Casting parts method and forging press for forging casting part with side opening or pleural furrow, and adjustable wrench

An adjustable wrench and casting technology, applied in the field of adjustable wrench, can solve the problems of reducing manpower and material resources, shortening production cycle, low manufacturing cost, etc., and achieving the effect of reducing production cost, saving manpower and material resources, and reducing clamping torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

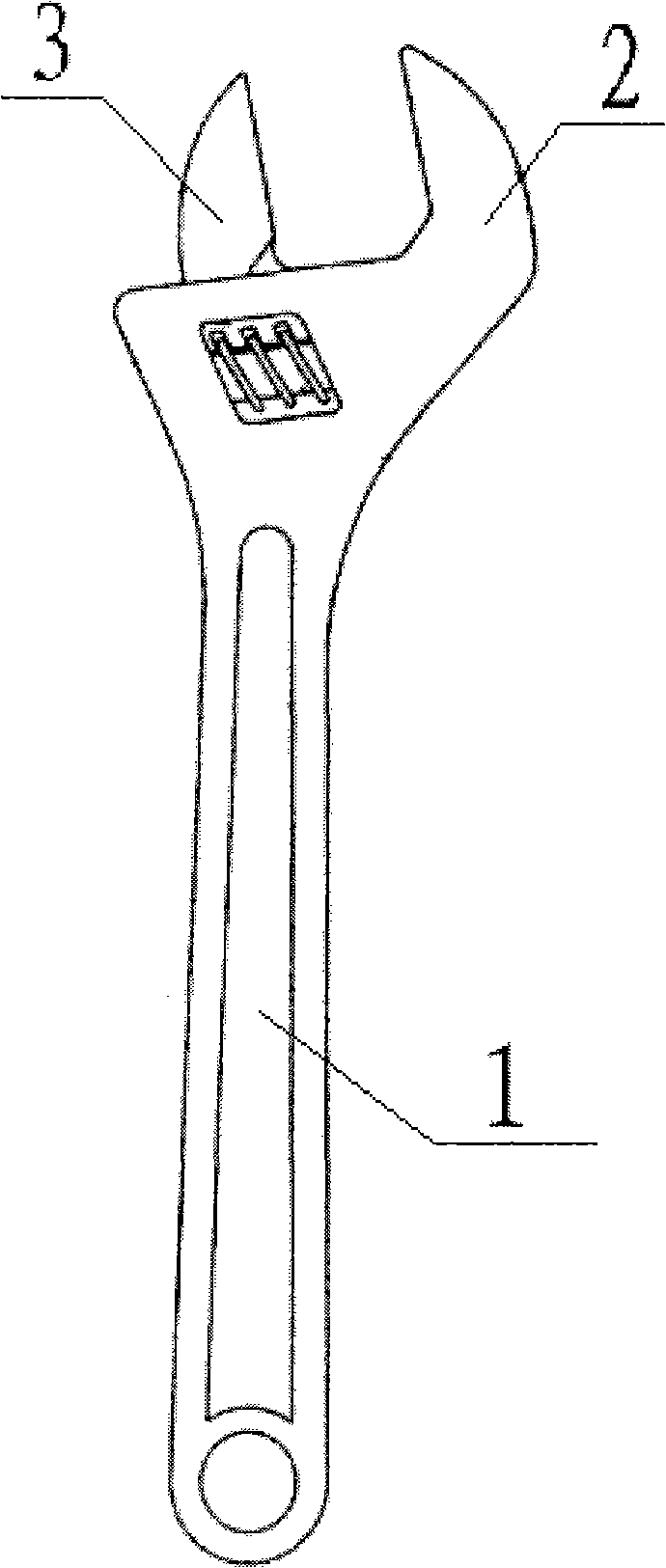

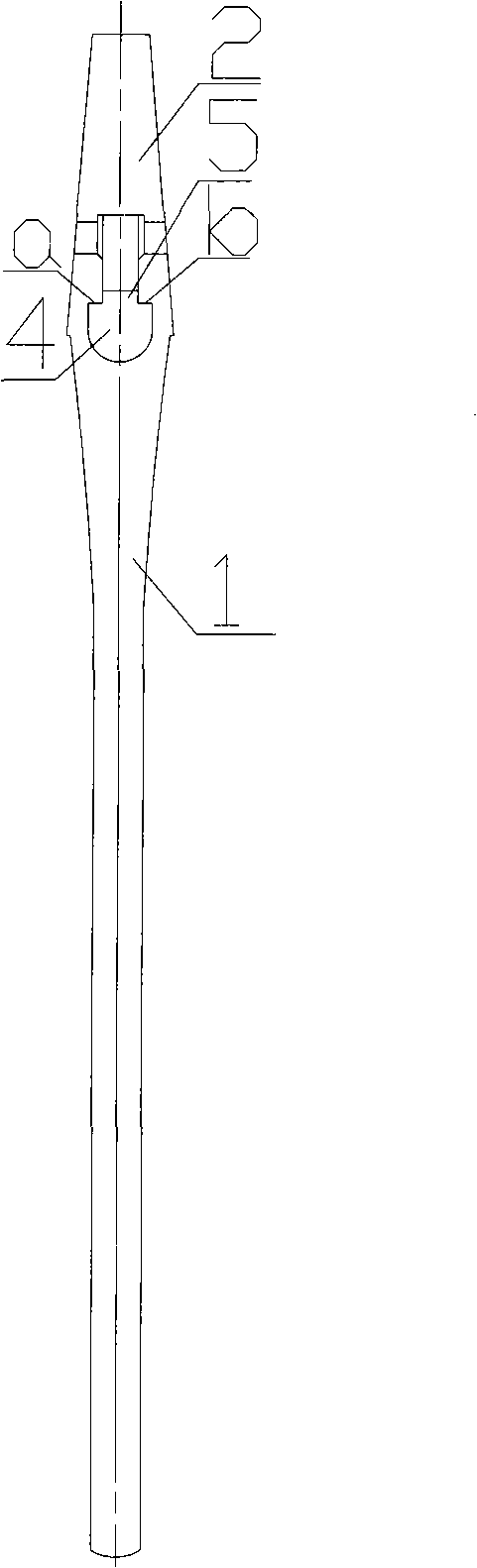

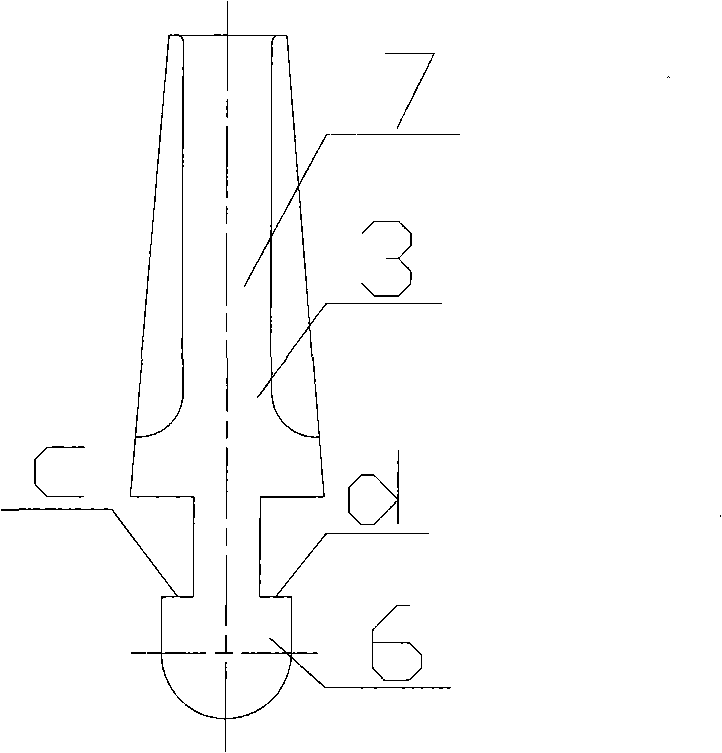

[0034] Such as figure 1 and figure 2As shown, the movable wrench includes a wrench body 1, a fixed jaw 2 and a movable jaw 3, the front end of the wrench body 1 is provided with a fixed jaw 2, and the fixed jaw 2 is provided with a sliding groove 4 and a sliding groove adjacent thereto. The rail 5 and the moving column 6 integrated with it are axially arranged below the movable jaw 3, and the moving column 6 is embedded in the sliding groove 4 and the sliding rail 5. The inner surfaces a and b of the slide groove 4 adjacent to the slide rail 5 are horizontal, and the corresponding outer surfaces c and d of the moving column 6 are also horizontal. When the wrench is working, the force acting on the inner surface of the sliding groove 4 is the force perpendicular to the a surface and the b surface, that is, the vertical force. This force has no component force in the horizontal direction, so the fixed jaw 2 and the movable jaw 3 can be eliminated. The gap between the adjustab...

Embodiment 2

[0046] This embodiment is the second production method of adjustable wrench, which adopts large-tonnage cold pressing, and mainly includes the following steps:

[0047] First, casting molding: the wrench body is initially formed by sand casting. Precision casting can also be used during casting, but it will increase production costs, and ordinary sand casting has already met the production requirements;

[0048] The second step is to detect the hardness of the wrench casting, and when the Rockwell hardness is less than HRC20, the casting is subjected to large-tonnage cold pressing;

[0049] The third step, forging: Put the wrench casting into the forging die, apply a small pressure on the wrench casting through the forging press, insert the side mold in the sliding groove of the wrench casting, the shape and size of the side mold must be consistent with the sliding groove The cross-sectional shape and size of the wrench are consistent, and then the wrench casting in the forgin...

Embodiment 3

[0053] Such as Figure 9 and Figure 10 There are three holes in the oil circuit connection cap of the automobile engine shown, wherein hole 15 and hole 16 are through holes, hole 14 is a blind hole, and the axis direction of hole 15 and hole 16 is perpendicular to hole 14, the oil circuit connection The processing method of the cap is as follows:

[0054] The first step, casting molding: the oil passage connecting cap is preliminarily formed by sand casting;

[0055] The second step, heating: reheat the casting of the cast oil connection cap to its plastic deformation temperature. The specific temperature value is determined according to the material of the oil connection cap;

[0056] The third step, precision forging: using such as Figure 8 In the forging press shown, put the heated oil passage connecting cap casting into the forging die. When putting it in, make the axial direction of the hole 15 and the hole 16 parallel to the axial direction of the forging press, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com