Lead recycling

A lead battery and lead citrate technology, applied in the field of lead recovery, can solve problems such as unpredictability, impact of lead waste, and difficulty in controlling the exact composition of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

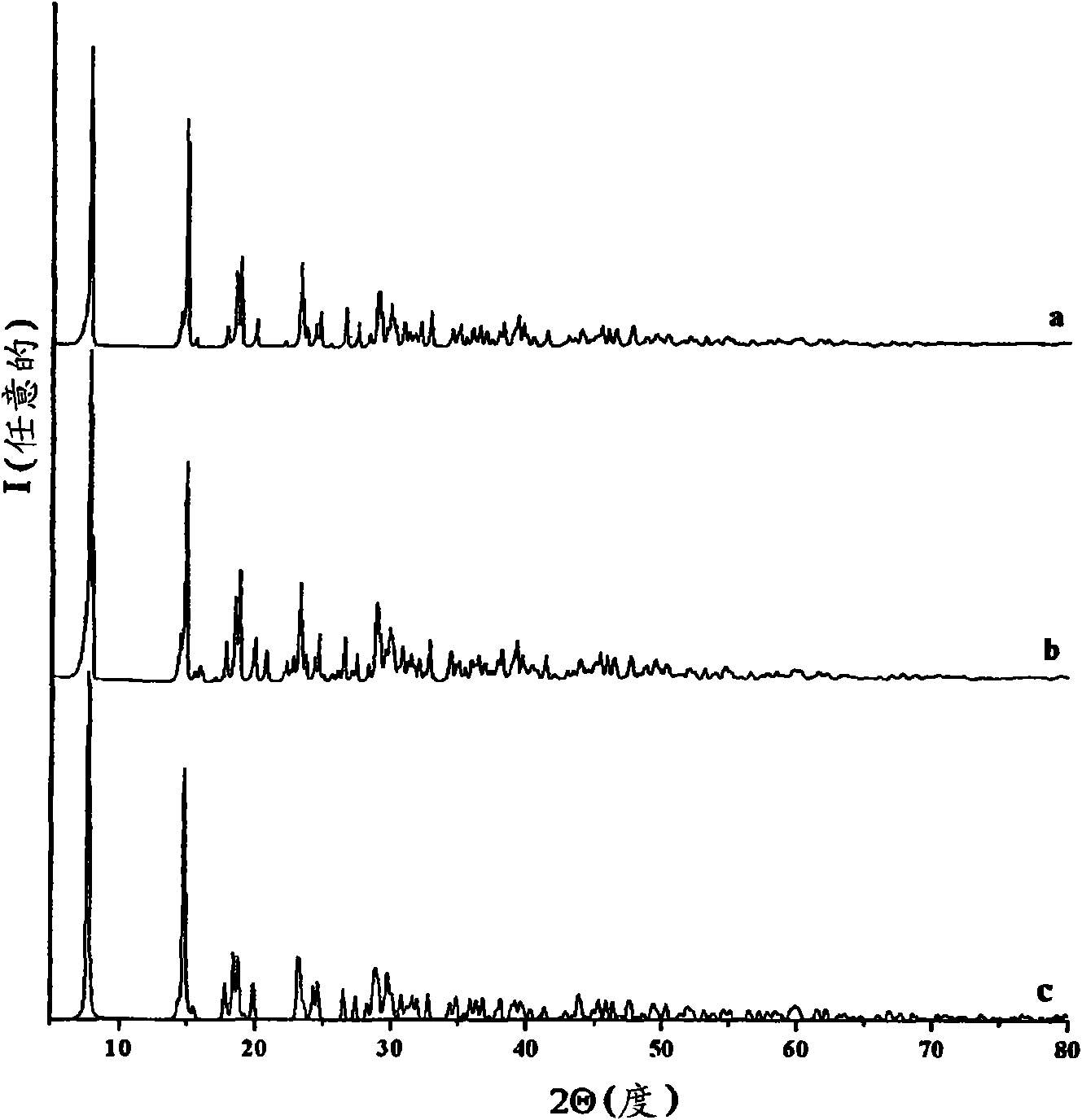

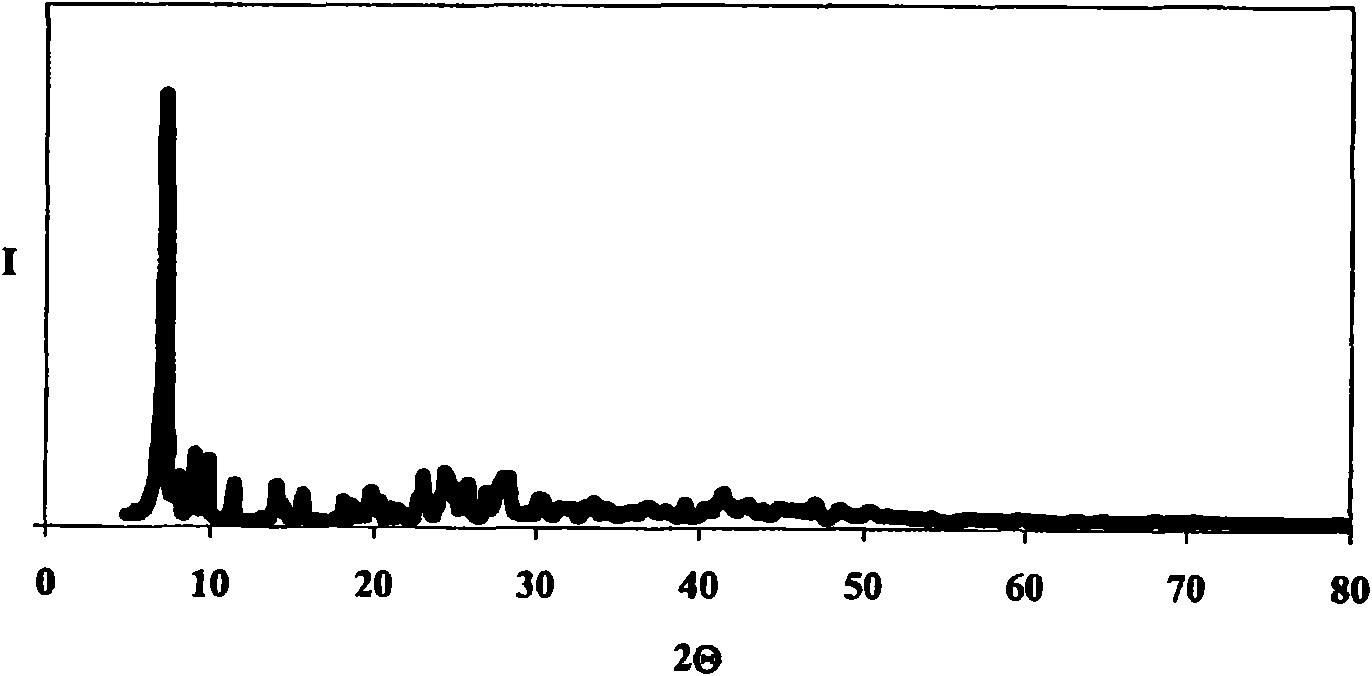

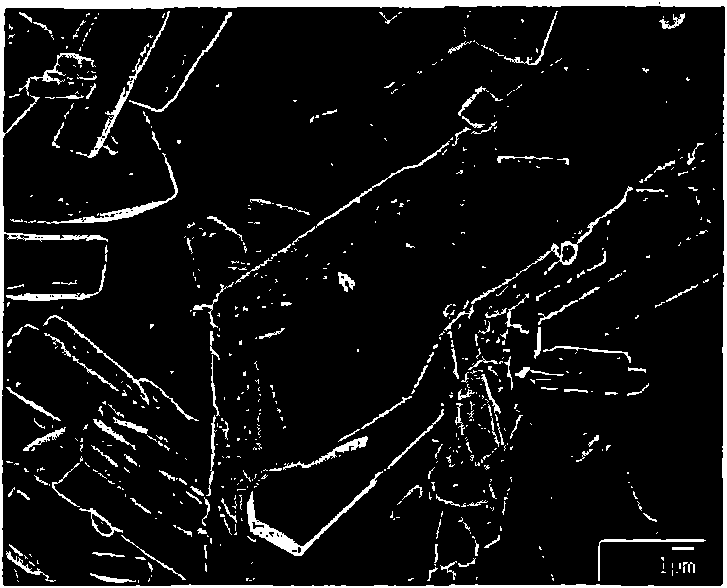

[0097] Synthesis of lead citrate

[0098] The reaction conditions suitable for the synthesis and recovery of lead citrate were studied. Preliminary experiments were performed using lead compounds available from commercial suppliers as models for spent battery pastes.

[0099] Analytical pure commercially available lead oxide (PbO, Acros Organics), lead dioxide (PbO 2 , Fisher Scientific), lead sulfate (PbSO 4 , Fisher Scientific), citric acid monohydrate (C 6 h 8 o 7 .H 2 O, Acros Organics) and, when appropriate, 27.5% hydrogen peroxide (H 2 o 2 ) aqueous solution (Aldrich) and trisodium citrate (Na 3 C 6 h 5 o 7 .2H 2 O, Fisher Scientific) was used as starting material.

[0100] The reaction was carried out in a beaker placed on a magnetic stirrer hot plate and equipped with a magnetic stirrer bar. In each experiment, the total volume of the aqueous citric acid solution was 30 mL. The reaction mixture was stirred at a constant rate of 250 rpm unless otherwise...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com