Recovery method for active matter from waste material containing lithium ionic cell anode active matter

A positive electrode active material and lithium-ion battery technology, which is applied in the field of recycling active materials in waste materials, can solve the problems of poor performance of positive electrode active materials and low recovery rate of positive electrode active materials, and achieve short roasting time, good dispersion and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example illustrates the recycling method of waste materials containing positive electrode active materials provided by the present invention.

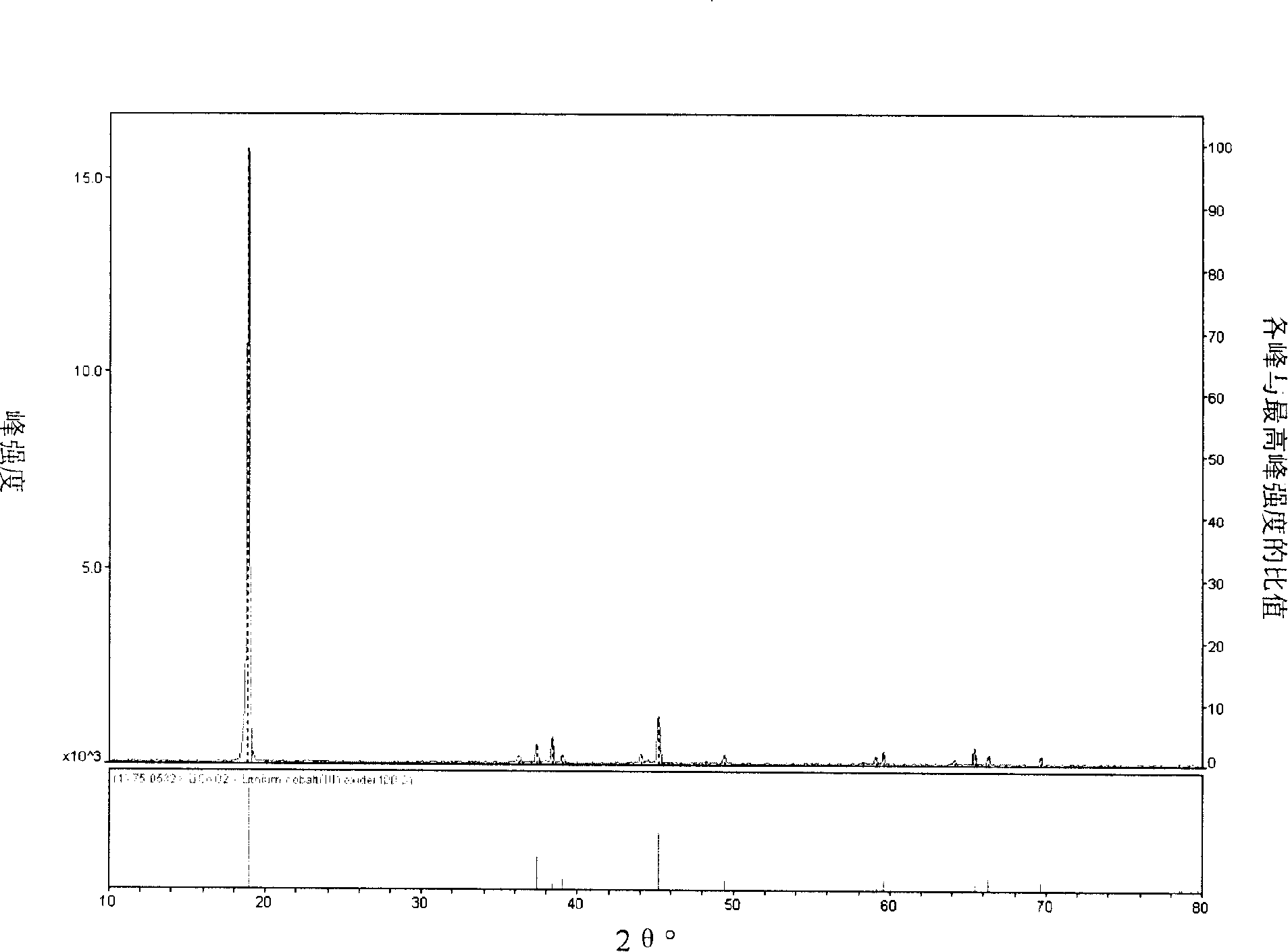

[0032] Under heating in a water bath at 85°C, 2000 grams of dry waste slurry containing lithium cobaltate and lithium manganate (active material in the dry waste slurry: acetylene black: polyvinylidene fluoride (PVDF) The weight ratio is 8:1:1) and 10,000 grams of N-methylpyrrolidone (NMP) are mixed evenly in a stirring tank with a volume of 15 liters, and stirred for 5 hours to make the binder polyvinylidene fluoride (PVDF) Fully dissolved in an organic solvent, the mixture was separated after standing for 15 hours, the upper layer of unsettled conductive agent and most of the adhesive dissolved in the organic solvent were poured off, and the lower layer of precipitate was separated. Then the lower layer of sediment was mixed with ethanol (the weight ratio of the lower layer of sediment to ethanol was 1: 0.7), and stirred ...

Embodiment 2

[0034] This example illustrates the recycling method of waste materials containing positive electrode active materials provided by the present invention.

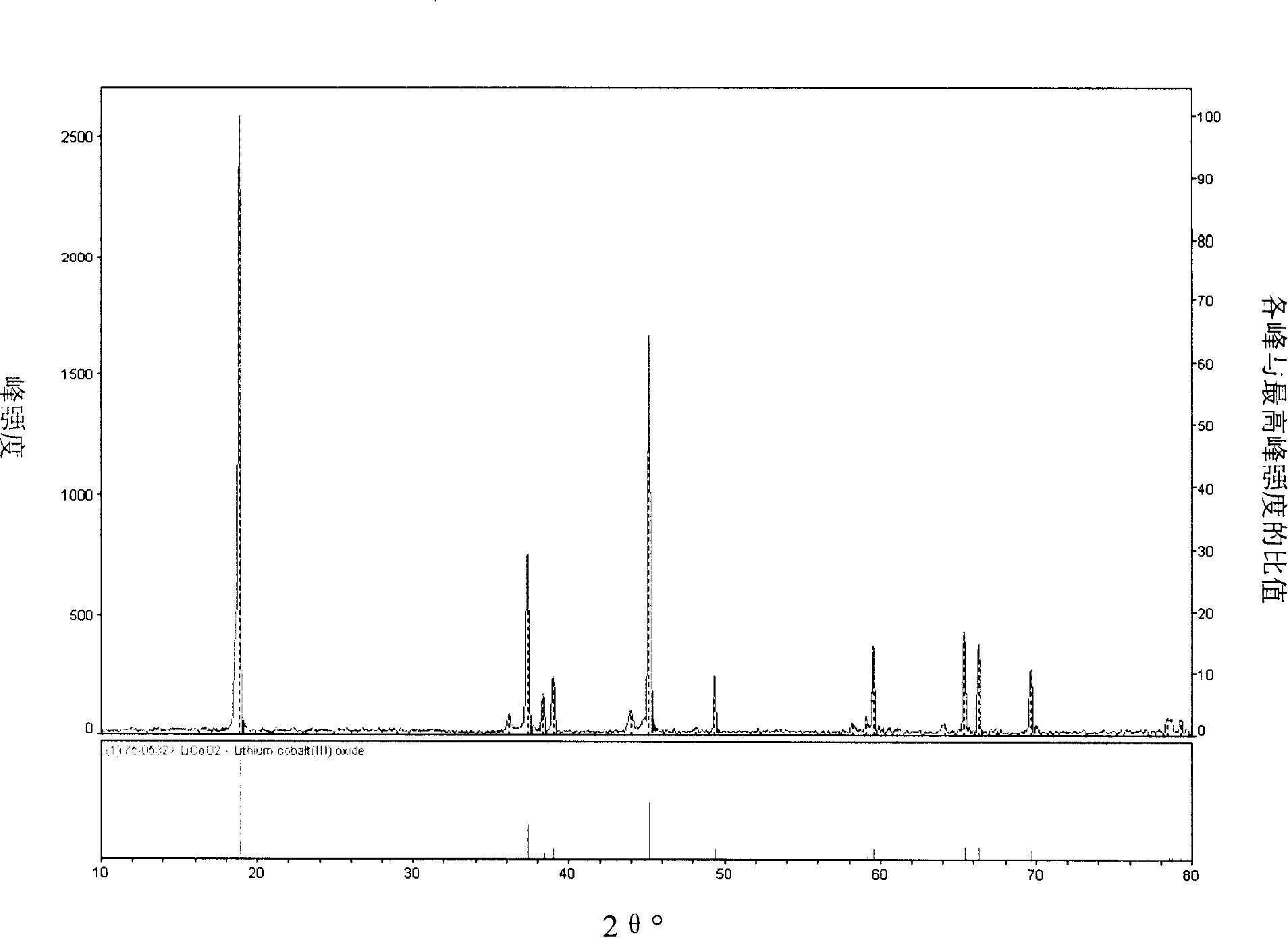

[0035] Under heating in a water bath at 85°C, 2500 grams of spent pole pieces containing lithium nickel manganese cobalt oxide (on the pole piece lithium manganese cobalt acid: acetylene black: the mass ratio of polyvinylidene fluoride (PVDF) is 8:1 : 1, the substrate is aluminum foil) and 8500 grams of N, N-dimethylacetamide in a volume of 15 liters of mixing tank mixed, and stirred for 5 hours, sieved to remove the aluminum foil (the aluminum foil weighed 196 after drying. gram). After standing still for 10 hours, the mixture was separated into layers, the upper layer of unsettled conductive agent and most of the adhesive dissolved in the organic solvent were poured off, and the lower layer of precipitate was separated. Then mix the lower layer of precipitate with isopropanol (the mass ratio of the lower layer of non-pre...

Embodiment 3

[0037] This example illustrates the recycling method of waste materials containing positive electrode active materials provided by the present invention.

[0038] Under heating in a water bath at 95°C, 3000 grams of spent pole pieces containing lithium nickel manganese cobalt oxide (on the pole piece lithium manganese cobalt acid: acetylene black: the mass ratio of polyvinylidene fluoride (PVDF) is 8:1 : 1, the substrate is aluminum foil) and 5000 grams of N, N-dimethylacetamide and 5000 grams of N-methylpyrrolidone (NMP) are mixed uniformly in a stirring tank with a volume of 15 liters, and stirred for 5 hours, and sieved The aluminum foil was removed (weighed 196 grams after the aluminum foil was dried). After standing still for 8 hours, the mixture was separated into layers, the upper layer of unsettled conductive agent and most of the adhesive were poured off, and the lower layer of sediment was separated. Mix the sediment in the lower layer with acetone (the mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com