Selectivity volatilization reclaiming technique for waste zinc-manganese battery and reclaiming system thereof

A zinc-manganese battery, a selective technology, applied in battery recycling, recycling technology, manganese sulfate and other directions, can solve problems such as being unsuitable for the overall economic situation, environmental pollution of waste zinc-manganese batteries, and high power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

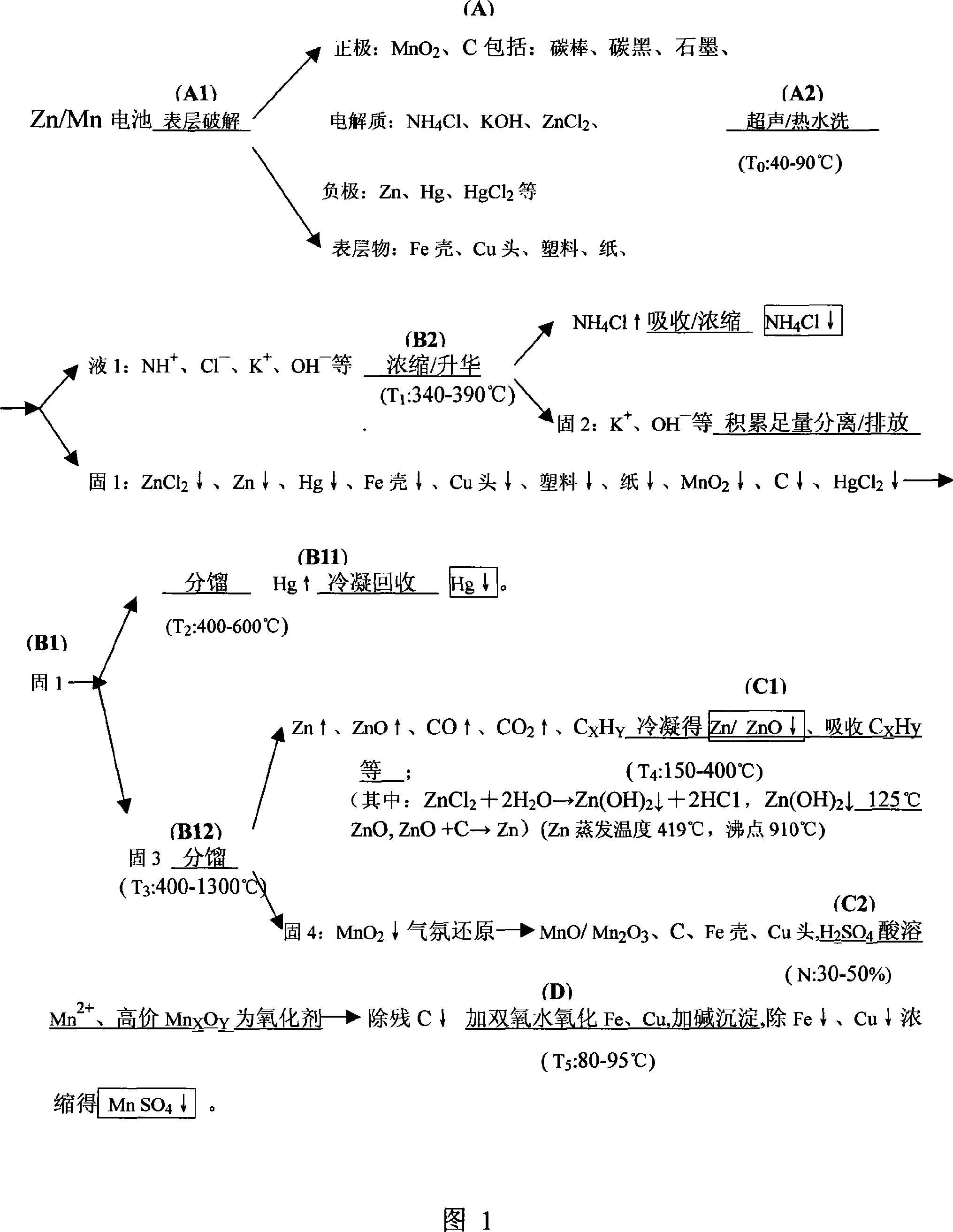

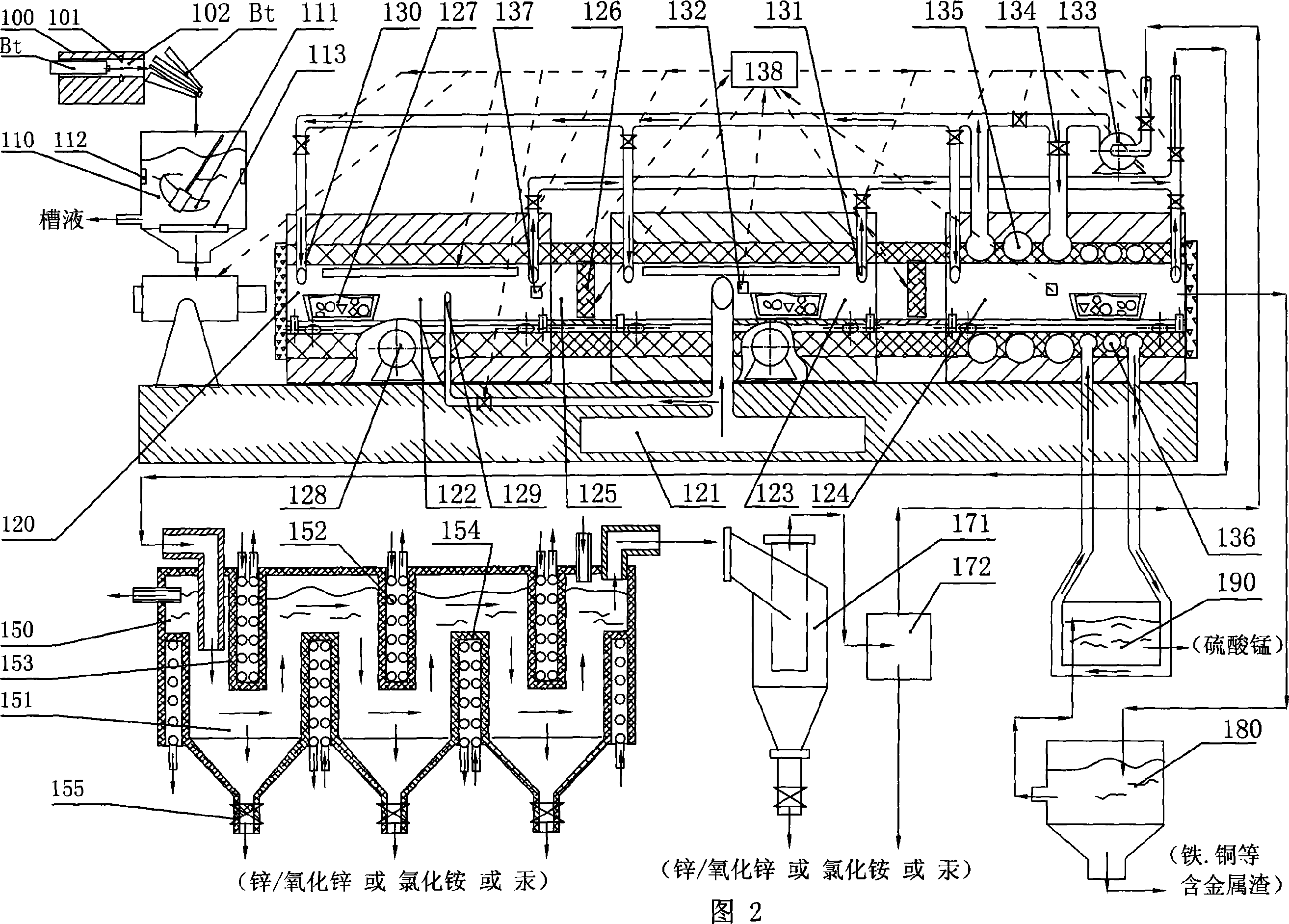

[0033] As shown in Figure 1, it is a selective volatilization recovery process embodiment of a waste zinc-manganese battery of the present invention. In Figure 1, the corresponding steps are represented by bold letters in brackets, and the main steps before and after the treatment of each step are briefly listed. Material composition, state, reference process and conditions, etc. The zinc-manganese battery includes an electrochemically active content and a coating surface layer, and the recovery process includes the following steps:

[0034] Step A):

[0035] A1- Decompose the surface layer of the waste zinc-manganese battery,

[0036] A2- Put the cracked and separated surface and contents in the washing tank, apply energy to the water body in the tank, and the water temperature in the tank T 0 , wash the surface and contents in the washing tank, so that the alkaline substances in the battery are dissolved in the tank water, and obtain the tank liquid, the cleaned surface an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com