Three-dimensional graphene-coated metal-organic framework (MOF) composite electrode material and preparation method thereof

A technology of graphene coating and electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of insufficient capacity, poor cycle stability, battery development, etc., and achieve improved utilization, superior electrochemical performance, Good electrical conductivity and the effect of encapsulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of graphene oxide:

[0028] Graphene oxide was prepared by the improved hummers method, specifically: take 0.5-5 g of 325 mesh-8000 mesh flake graphite powder, add 0.2-2.5 g of sodium nitrate powder, and then add 10-120 ml of concentrated sulfuric acid, concentrated phosphoric acid, and concentrated nitric acid One or more of them, stir for 5~30 min, slowly add 2~20 g of potassium permanganate, potassium perchlorate, and potassium carbonate in an ice-water bath. Stir in a water bath for 0.5~3 h, then add a small amount of water, continue the reaction for 10~30min, then add a large amount of water above 100 ml, react for 5~20min, and then add an appropriate amount of hydrogen peroxide until the solution turns golden yellow;

[0029] After the solution was allowed to settle, the supernatant was removed by decantation, an appropriate amount of 5% to 10% hydrochloric acid was added, and the solution was divided into centrifuge tubes for high-speed centrifuga...

Embodiment 2

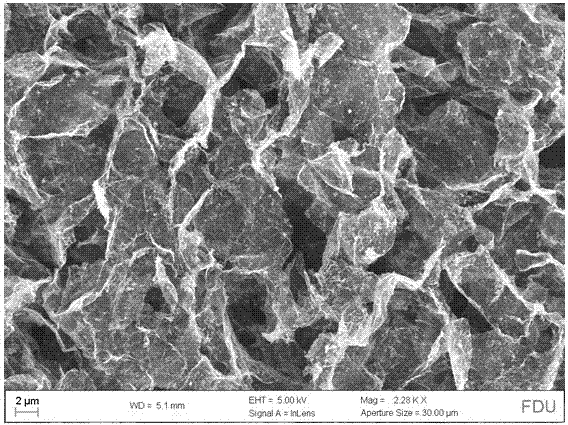

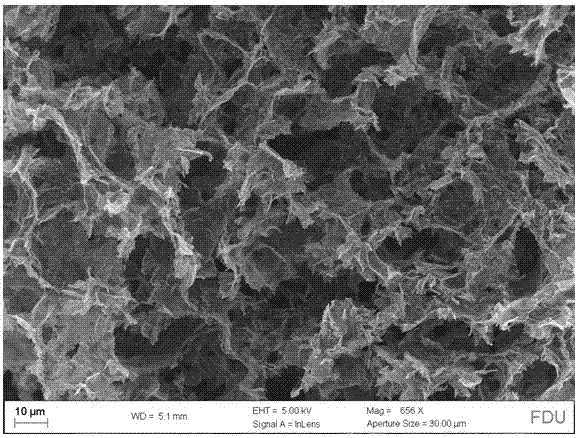

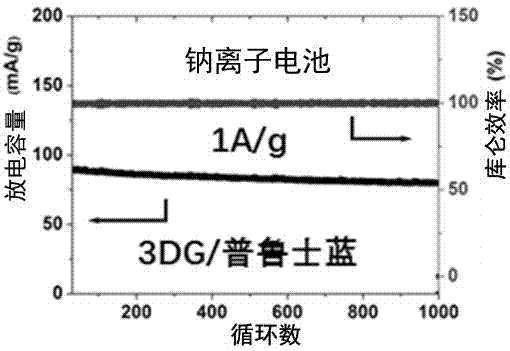

[0035] The 2 mg / mL GO aqueous solution was obtained by the method in the above Example 1, 0.02 mL of 0.5 mol / L potassium ferrocyanide solution was added to the 2 mg GO aqueous solution under stirring, and 0.2 mL of 0.5 mol GO was added after shaking well. / L ferric chloride solution, then add an appropriate amount of 1 M sodium ascorbate aqueous solution, mix evenly, and heat in an oven at 90-100 °C for 1-2 h to obtain a hydrogel of Prussian blue supported on graphene (3DG / PB), washed with water After 3 to 5 times, it was placed in the refrigerator for 1 to 3 hours, and then lyophilized for 16 to 24 hours to obtain a self-supporting 3DG / PB aerogel ( figure 1 ). The obtained composite gel was used as a cathode material for sodium-ion batteries, and the capacity after 1000 cycles at a current density of 1 A / g remained at 85 mAh / g ( image 3 ).

Embodiment 3

[0037] The 2 mg / mL GO aqueous solution was obtained by the method in the above Example 1, and 0.02 mL of 0.5 mol / L sodium ferrocyanide solution was added to the 2 mg GO aqueous solution under stirring, and 0.2 mL of 0.5 mol GO was added after shaking well. / L nickel chloride solution, then add an appropriate amount of 1 M sodium ascorbate aqueous solution, mix well and heat in an oven at 90-100 °C for 1-2 h to obtain a hydrogel of nickel ferricyanide supported on graphene (3DG / PBA) , washed with water for 3 to 5 times, placed in the refrigerator for 1 to 3 hours, and then lyophilized for 16 to 24 hours to obtain self-supporting 3DG / PBA aerogels. The obtained composite gel was used as a cathode material for sodium-ion batteries, and the capacity after 1000 cycles at a current density of 0.5 A / g remained at 50 mAh / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com