Detecting method and device for lithium ion cell material

A lithium-ion battery and material testing technology, which is applied in the direction of measuring devices, material analysis through electromagnetic means, and material analysis, can solve the problems of large deviation of results, long cycle, and inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Electrode Preparation Method 2

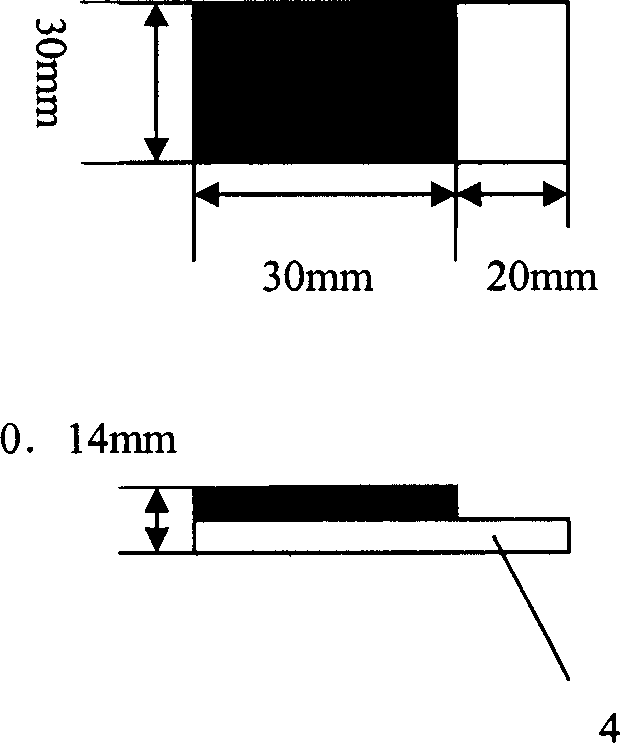

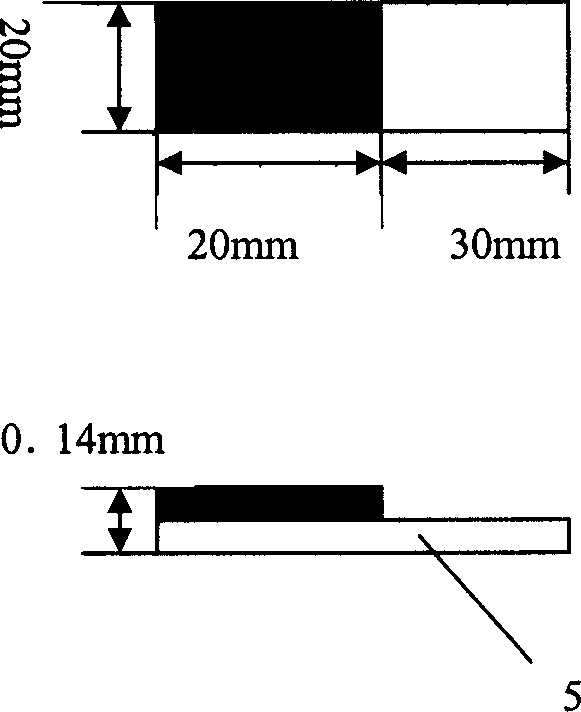

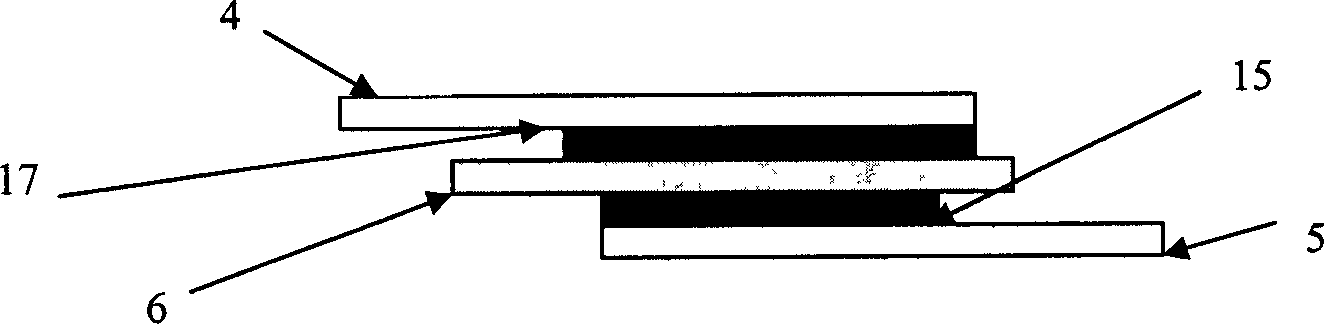

[0029] see figure 1 , the conductive agent, the binder, and the solvent are formulated into a positive electrode slurry according to the required ratio, and coated on a single surface of the aluminum foil 4 to make the above negative electrode 12, and cut into the size shown in the figure. see figure 2 , the conductive agent, binder, and solvent are made into a negative electrode slurry according to the required ratio, and coated on a single surface of the copper foil 5 to make the above positive electrode 14, and cut into the size shown in the figure. These conductive agents, binders, and solvents will vary due to testing different technical indicators.

[0030] After the positive electrode slurry and the negative electrode slurry are dried under high temperature to remove the solvent, they become the positive electrode active material 15 and the negative electrode active material 17 respectively, and are attached to the surfaces of ...

Embodiment 1

[0040] Example 1: Testing the limit gram specific capacity of the negative electrode material

[0041] Definition: "Limited gram specific capacity" refers to the capacity charged per gram of pure negative electrode material when the negative electrode material of the lithium ion battery is completely filled with lithium ions in the interlayer space without dendrite lithium precipitation.

[0042]The manufacturing method of the research electrode (negative electrode): 10 g of polyvinylidene fluoride (PVDF) was dissolved in N-methyl-2-pyrrolidinedione (NMP), and 100 g of the tested negative electrode graphite powder was added. A slurry-like negative electrode slurry is uniformly prepared by high-speed stirring, and the negative electrode slurry is coated on a single surface of a copper foil with a thickness of 20 microns. Dry at 120°C to remove N-methyl-2-pyrrolidinedione (NMP), the thickness of the electrode strip is controlled at 160±10 microns, the thickness of the electrode ...

Embodiment 2

[0051] Example 2: Testing of Limit Failure Gram Specific Capacity of Lithium-ion Battery Cathode Material

[0052] "Limited failure gram specific capacity of positive electrode material" refers to the capacity released when each gram of pure positive electrode material is discharged when the lithium ions in the interlayer space of the positive electrode material of the lithium ion battery are completely released (the crystal structure of the positive electrode material is completely destroyed at this time). .

[0053] Manufacturing method of auxiliary electrode (negative electrode): Dissolve 10g polyvinylidene fluoride (PVDF) in N-methyl-2-pyrrolidinedione (NMP), then add 3g Super-P, and finally add 100g Negative electrode graphite powder. A slurry-like negative electrode slurry is uniformly prepared by high-speed stirring, and the negative electrode slurry is coated on a single surface of a copper foil with a thickness of 20 microns. Dry at 120°C to remove N-methyl-2-pyrrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com