Method for preparing mesoporous carbon material

A mesoporous carbon and mesoporous technology, applied in the field of preparing new mesoporous materials, can solve the problems of high cost and cumbersome process of mesoporous carbon materials, and achieve the effect of simple method and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, the preparation condition of phenolic resin prepolymer is as follows: 32.0g phenol is melted under 45 ℃ of conditions, add 7.0g mass percent concentration and be 20wt.%NaOH aqueous solution and 56.64g formaldehyde solution (37wt.%), at 65 Reflux at -70°C for 1 hour, after cooling to room temperature, adjust the pH to about 7 with 0.6M hydrochloric acid solution, place the reaction system in a water bath lower than 50°C and distill off water under reduced pressure to obtain 24.8g of the polymer precursor ( Molecular weight 200-500). The obtained 24.8g polymer prepolymer was dissolved in 99.2g ethanol, and the ethanol solution of the phenolic resin prepolymer with a mass percent concentration of 20wt.% was configured for future use.

Embodiment 2

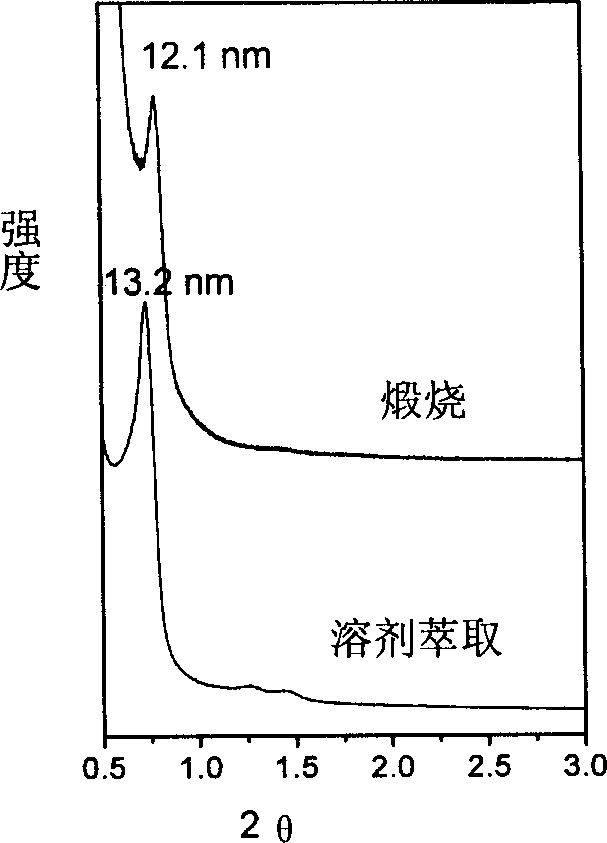

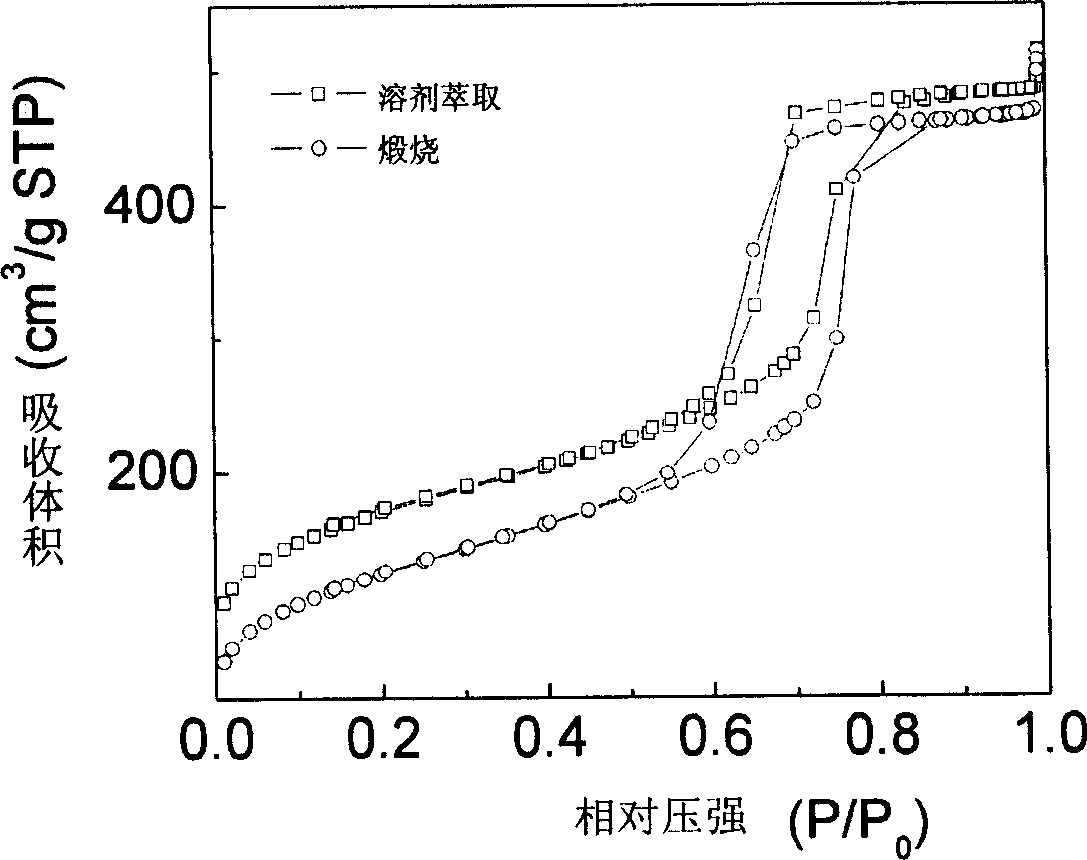

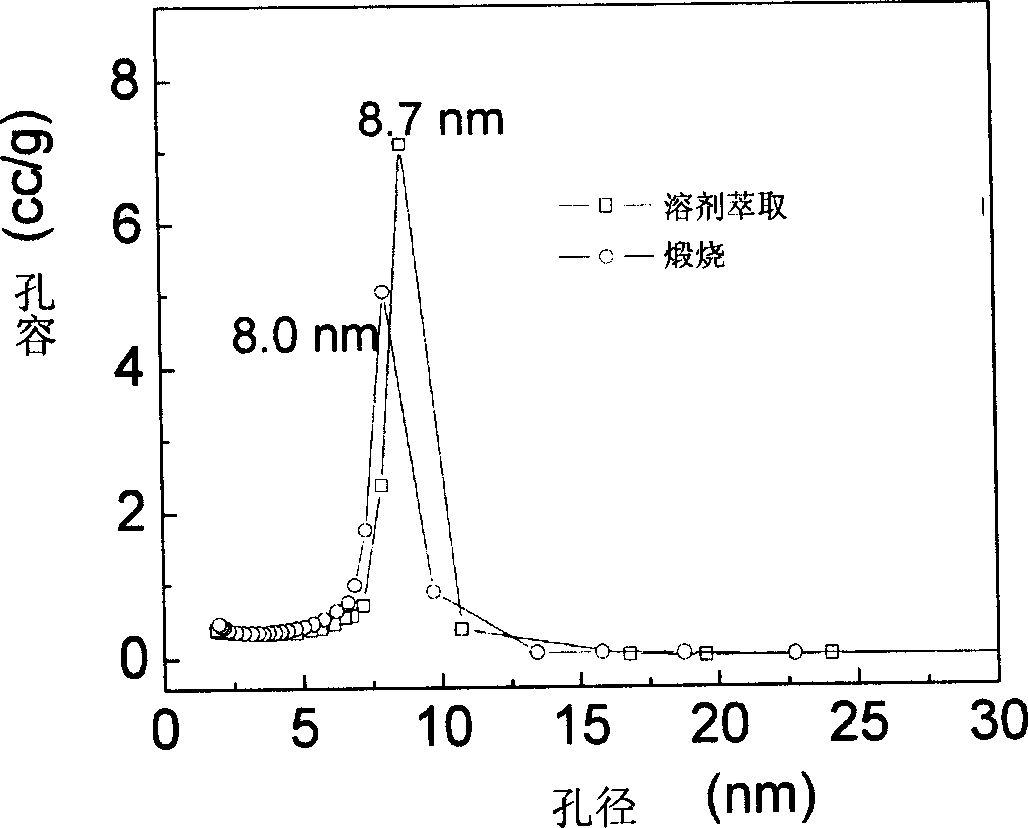

[0041] Example 2, 1.0g F127(EO 106 PO 70 EO 106 ) and 1.0g 0.2M hydrochloric acid solution were dissolved in 10.0g absolute ethanol, stirred to obtain a clear solution, adding 2.5g mass percent concentration in this solution was the alcohol solution of 20wt.% phenolic resin prepolymer and 2.08g Orthoethyl silicate (TEOS), stirred for 2 hours to make TEOS undergo preliminary hydrolysis and polycondensation. The solution was transferred to a watch glass, left to evaporate at room temperature, and then placed in an oven at 100°C for 24 hours for further polymerization to obtain 1.75 g of F127 / polymer / silicon dioxide composite material. Reflux 1.75g of F127 / polymer / silica composite material in 0.1M HCl ethanol solution at 78°C for 24 hours, filter and dry to obtain 0.85g of mesoporous polymer / silica composite material (wherein the polymer The mass percent content is 55wt.%, and the mass percent content of silicon is 45wt.%). This material has a pore diameter of 8.7nm and a p...

Embodiment 3

[0042] Example 3, 1.0g F127(EO 106 PO 70 EO 106 ) and 1.0g 0.2M hydrochloric acid solution were dissolved in 10.0g absolute ethanol, stirred to obtain a clear solution, adding 2.5g mass percent concentration in this solution was the alcohol solution of 20wt.% phenolic resin prepolymer and 2.08g Orthoethyl silicate (TEOS), stirred for 2 hours to make TEOS undergo preliminary hydrolysis and polycondensation. The solution was transferred to a watch glass, left to evaporate at room temperature, and then placed in an oven at 100°C for 24 hours for further polymerization to obtain 1.75 g of F127 / polymer / silicon dioxide composite material. The polymerized composite material was roasted at 350° C. for 2 hours under a nitrogen atmosphere to obtain 0.8 g of mesoporous polymer / silicon dioxide composite material (wherein the mass percentage of polymer was 52 wt.%, and the mass percentage of silicon Content is 48wt.%). This material has a pore diameter of 8.0nm and a pore volume of 0.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com