Extrusion blown molded bottles with high stiffness and transparency

A technology of high melt strength and nucleating agent, applied in the field of new products containing the polypropylene composition, can solve the problems of uneven surface properties, inability to produce visbreaking polypropylene, low transparency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

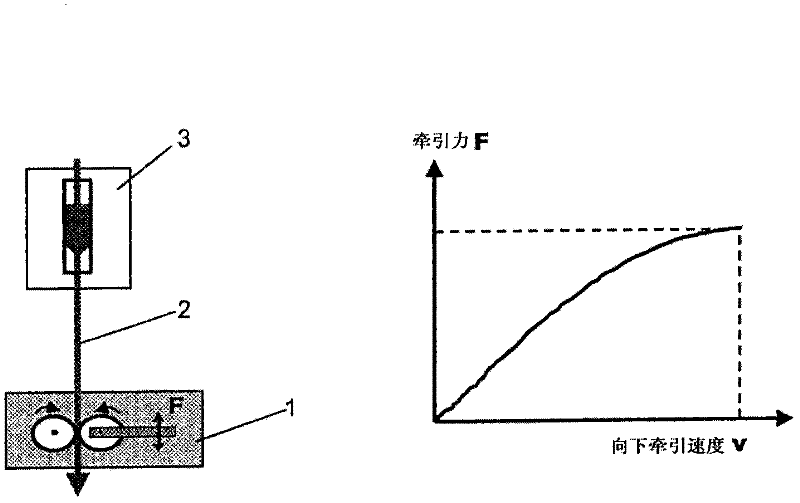

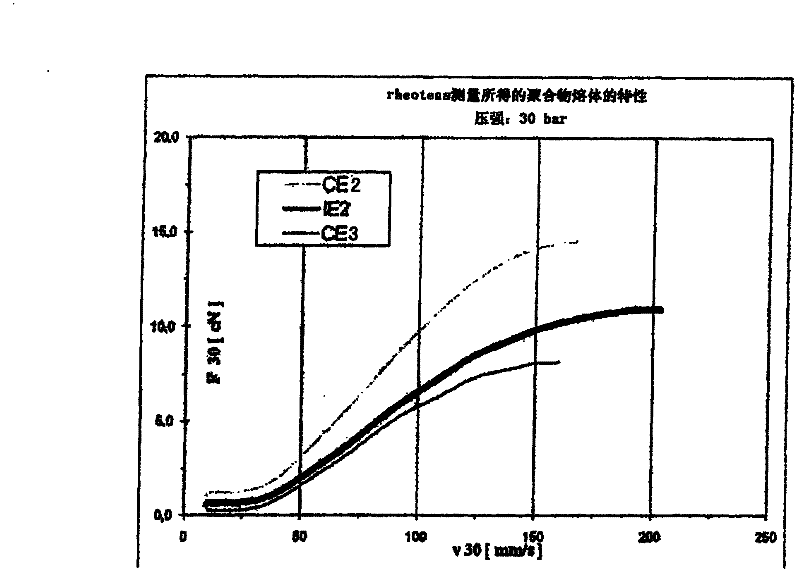

Image

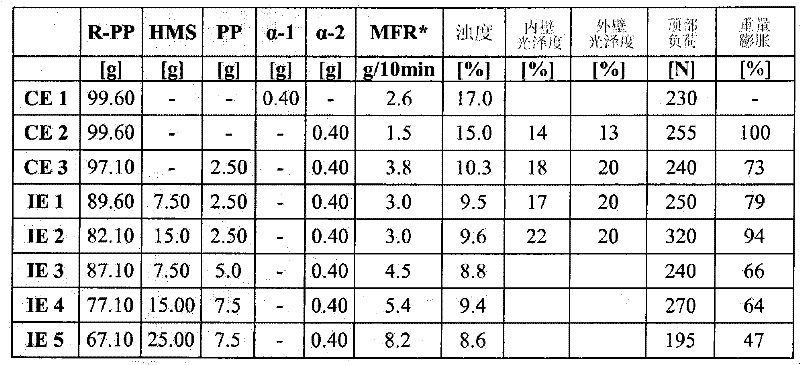

Examples

preparation example Construction

[0052] The preparation of the polypropylene copolymer (R-PP) will be described in more detail below.

[0053] As another essential requirement of the present invention, high melt strength polypropylene (HMS-PP) must be used. This polymer type is characterized by a certain degree of branching. A possible high melt strength polypropylene (HMS-PP) is known as Y / H-polypropylene, described for example in EP 0 787 750, i.e. a single branched polypropylene type (Y-polypropylene, having a backbone and A type of polypropylene in which a single long side chain, similar in structure to "Y"), and its inner polymer chains are connected by bridging groups (structurally similar to "H"). These polypropylenes are characterized by a rather high melt strength. One parameter of the degree of branching is the branching index g'. The branching index g' is related to the number of branches in the polymer. The branching index g' is defined as g'=[IV] br / [IV] lin , where g′ is the branching coe...

Embodiment

[0155] 1. Definition / measurement method

[0156] Unless otherwise stated, the following definitions of terms and measurement methods apply to the above general description of the invention and to the following examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| traction force | aaaaa | aaaaa |

| traction force | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com