High heat and chlorine resistant polyurethaneurea elastic fiber and preparation of thereof

一种弹性纤维、聚氨酯脲的技术,应用在连续聚合制备该聚氨酯脲弹性纤维领域,能够解决滤压降低可纺性、差分散性、黄色等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

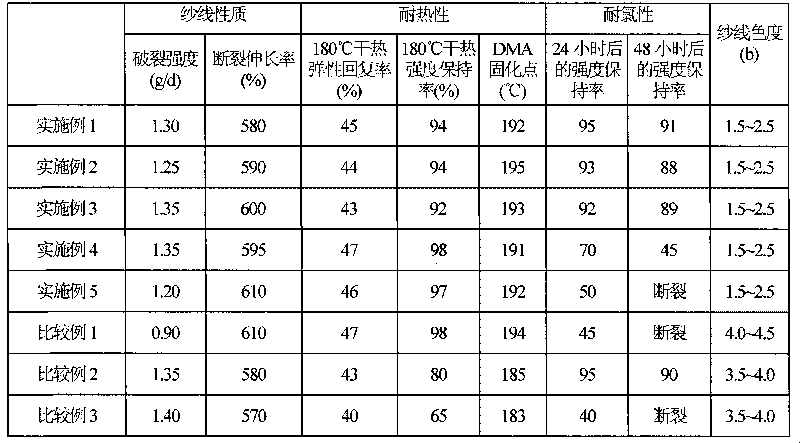

Examples

Embodiment 1

[0093] 305.80 g of polytetramethylene ether glycol (molecular weight: 1815) and phosphoric acid (molecular weight: 98.0, 7 ppm based on the weight of polytetramethylene ether glycol) were mixed. Charge 72.72 g of diphenylmethane-4,4'-diisocyanate into a static mixer using a metering pump at 40 °C and mix with the above mixture, which is charged into a cylindrical tubular continuous polymerization tube at 80 °C , followed by 135 minutes of reaction. The reaction was adjusted so that the content of unreacted diisocyanate at the end was 2.64 mol%. Thus, a primary polymer having a viscosity of 620 poise was synthesized.

[0094] The primary polymer was cooled to 40°C and then stabilized within 24 hours. The polymer was continuously charged into the high shear mixer along with 608.78 g of N,N-dimethylacetamide followed by vigorous stirring at 3500 rpm for 20 seconds before charging the polymer to the secondary reactor. The primary polymer was completely dissolved and cooled to 4...

Embodiment 2

[0101] Elastic fibers were prepared according to the same method described in Example 1, except that 90 ppm of diethylenetriamine was used as a viscosity stabilizer and a crosslinking agent.

Embodiment 3

[0103] Elastic fibers were prepared according to the same method described in Example 1, except that diethylamine and 230 ppm of diethylenetriamine were added as viscosity based on the chain extender (ethylenediamine) solution in a 1 / 14 amine equivalent ratio Stabilizers and crosslinkers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elastic recovery ratio | aaaaa | aaaaa |

| strength retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com