Predicting method for lithiumion cell heat safety performance

A lithium-ion battery, safety performance technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem of spending a lot of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation methods and features provided according to the present invention are described in detail as follows:

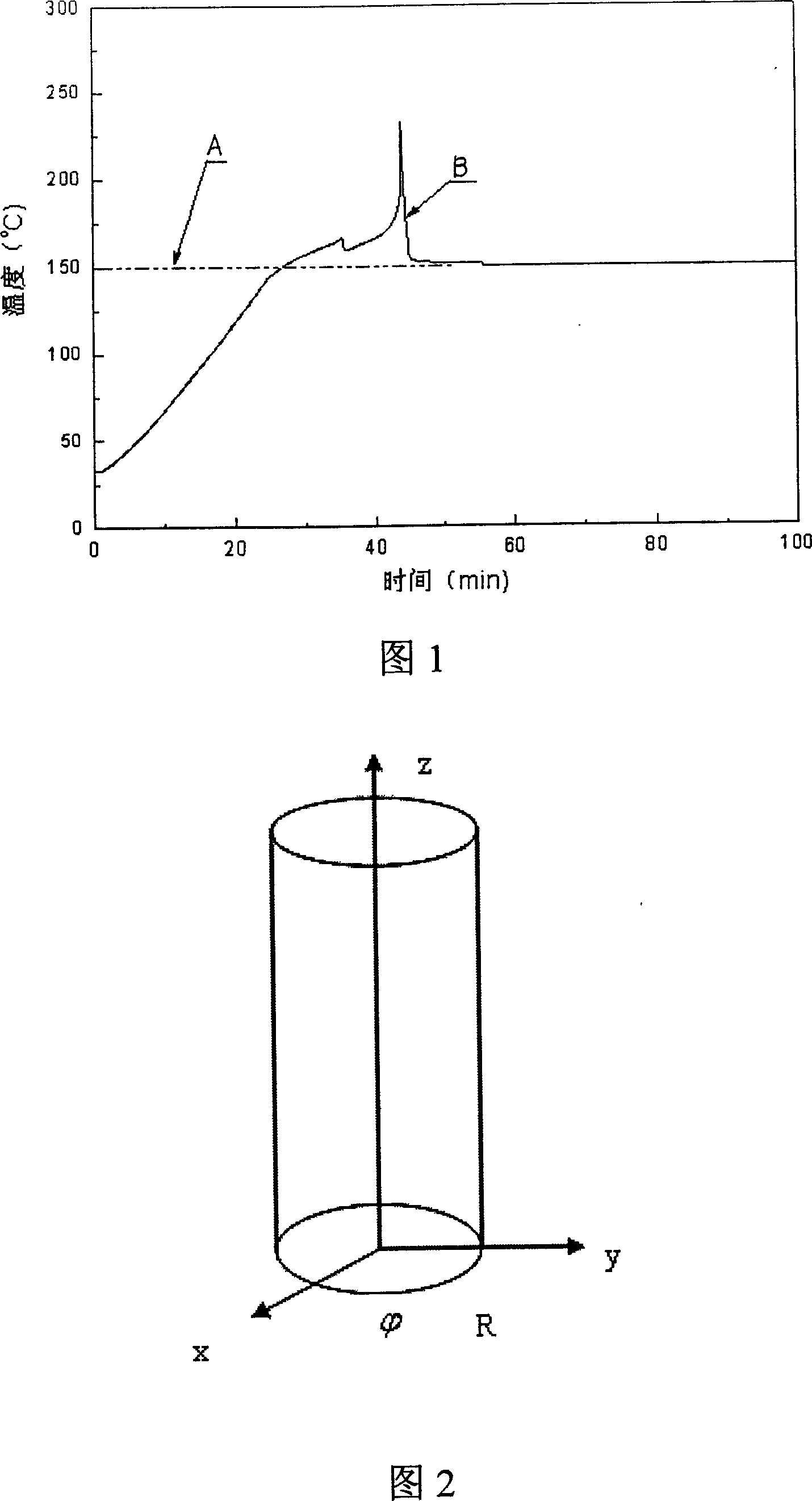

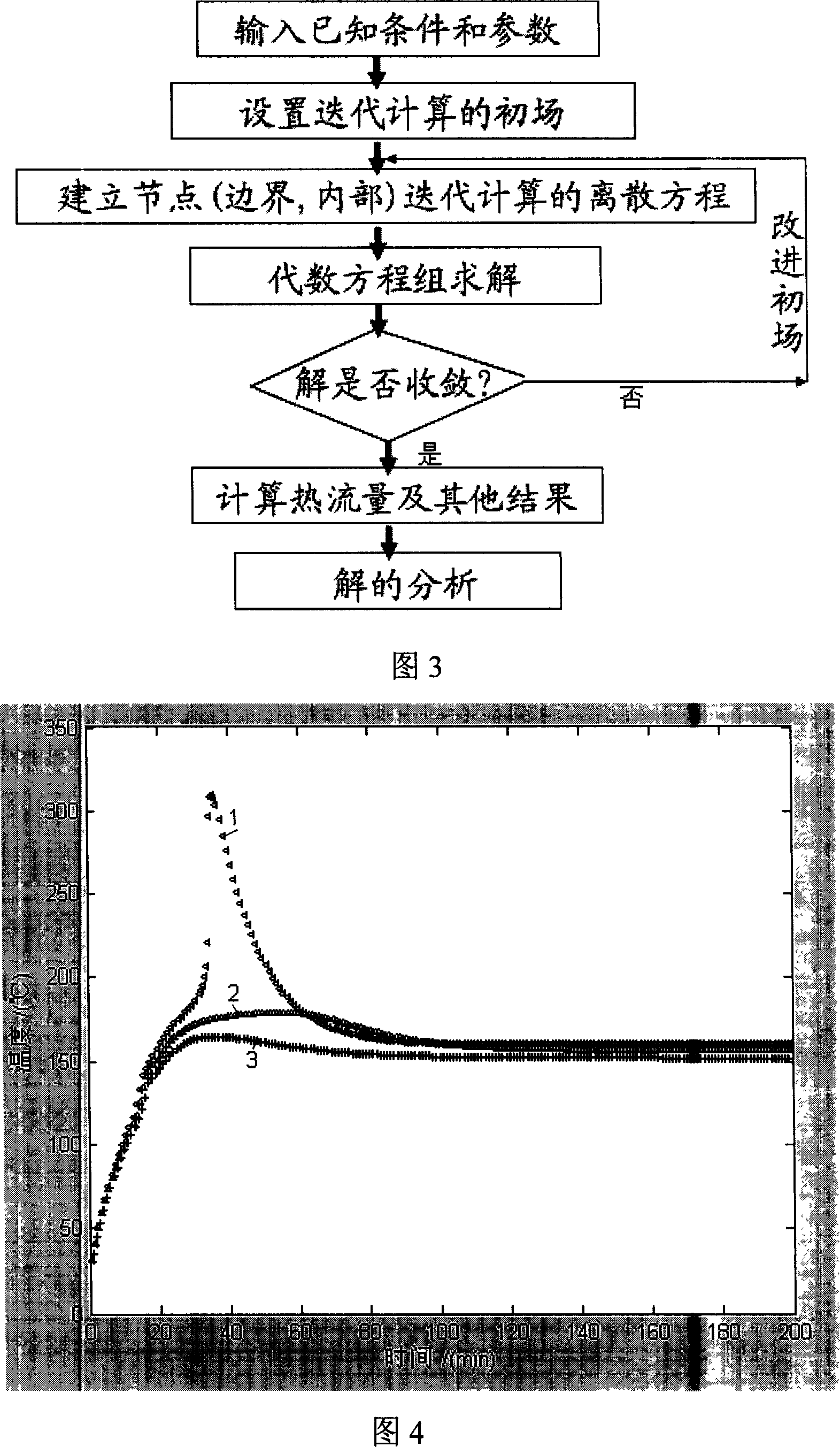

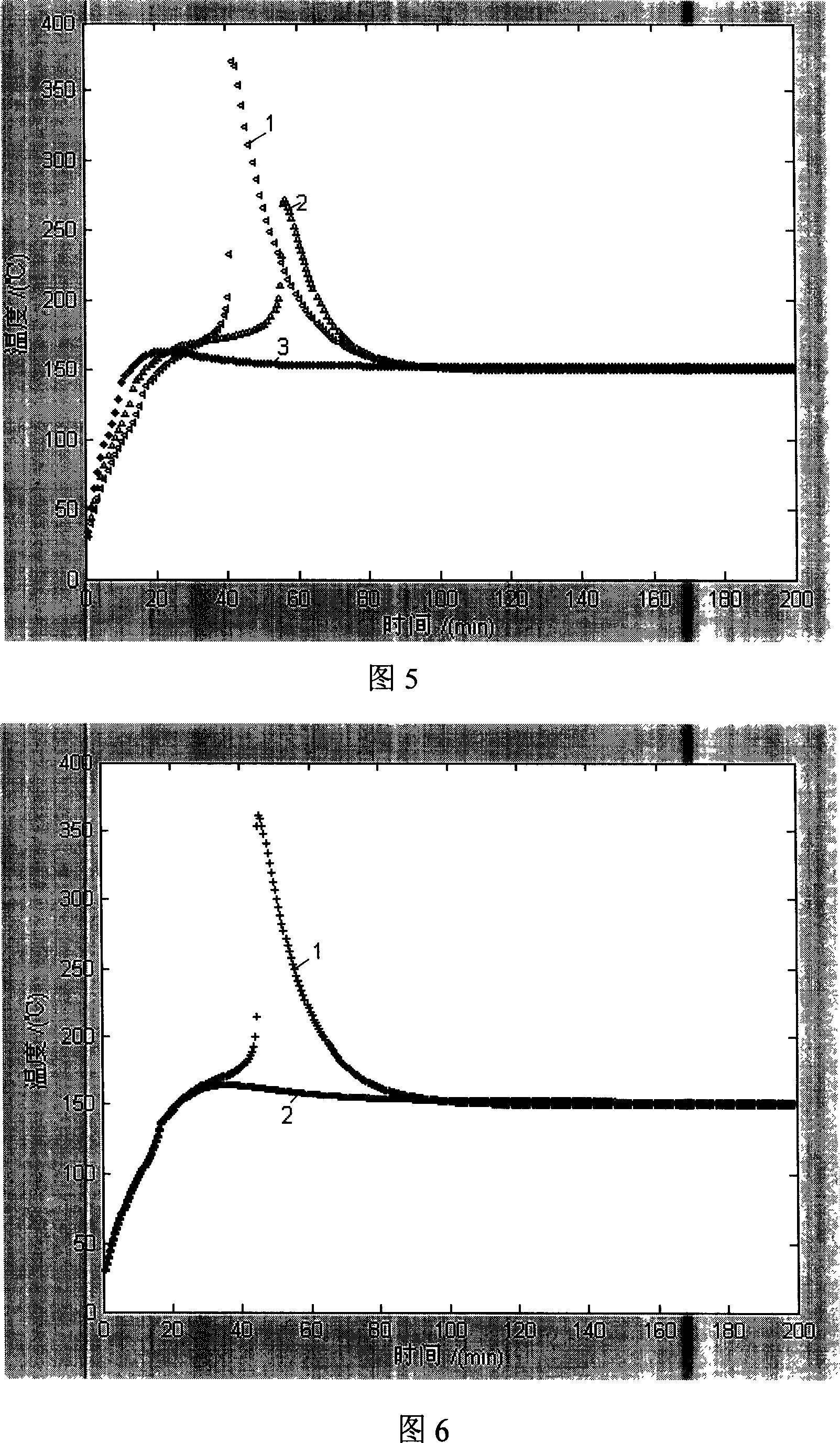

[0021] Referring to Figures 1-7, this representative example is simulated in a hot box test to illustrate the invention in further detail.

[0022] Description of hot box experiment:

[0023] The hot box test is one of the UL1642 lithium-ion battery safety standard experiments. Because the hot box test results are usually very repeatable, this makes the hot box test more generalizable than other methods in verifying the safety of lithium-ion batteries. The test is to attach a thermocouple to the surface of the battery, place the battery in a hot box, and heat the battery to a higher temperature at a heating rate of 5±1°C / min from an initial temperature (room temperature). For commercial batteries, the temperature of the hot box is generally required to be 150°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com