Filter device

A filter and equipment technology, applied in the field of filter equipment, can solve the problems of process safety and equipment availability still to be improved, and achieve the effect of reducing mechanical load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

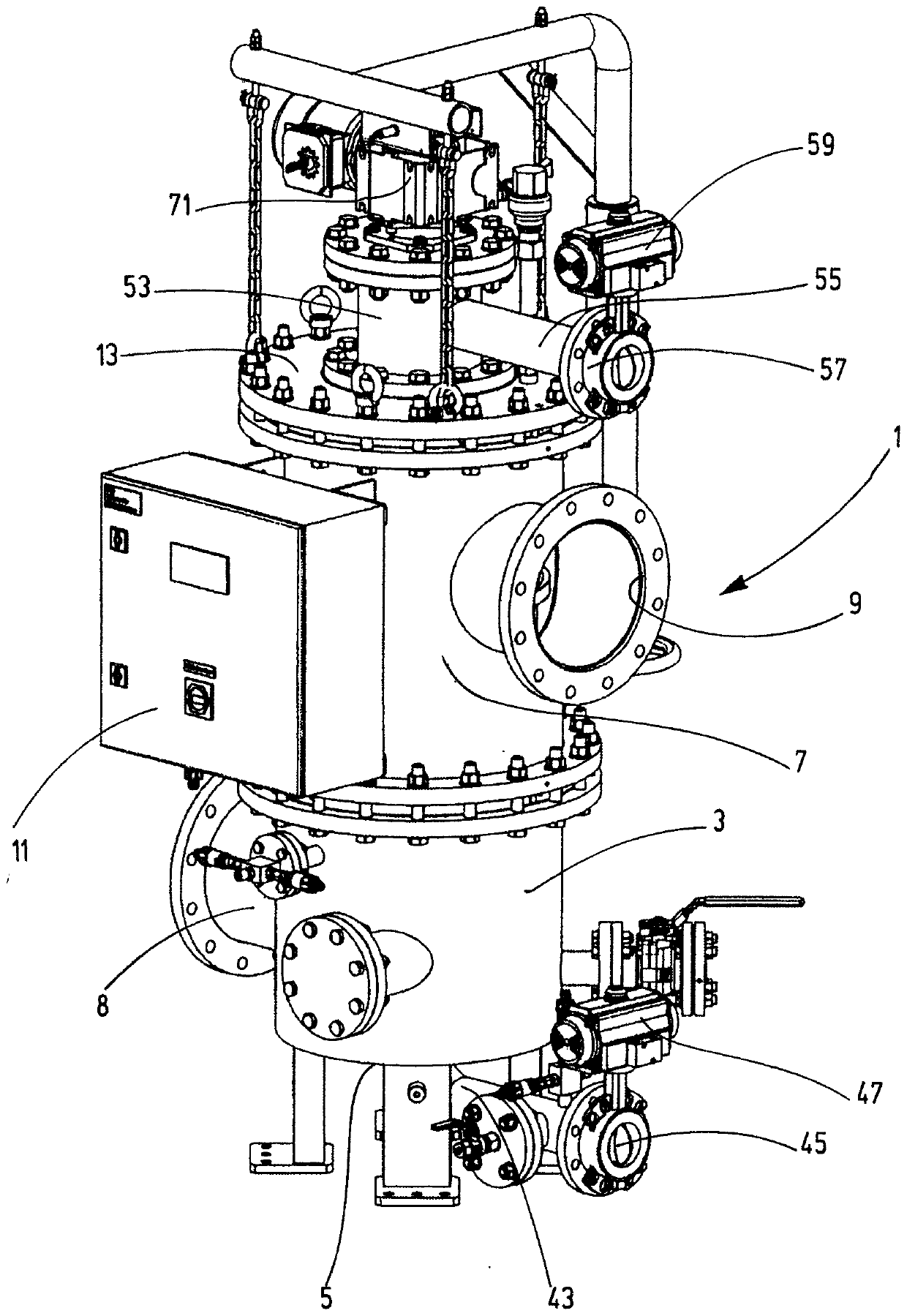

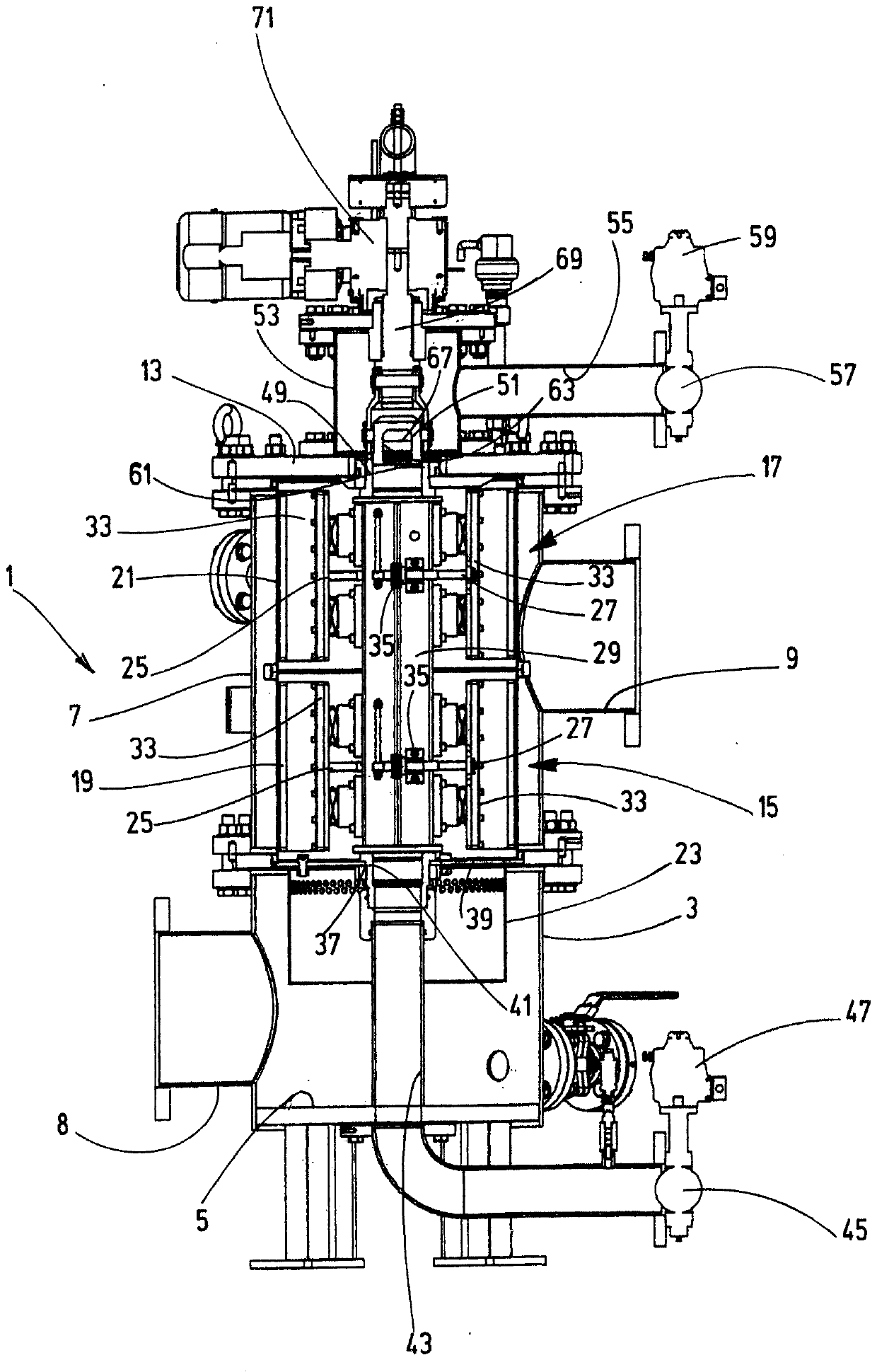

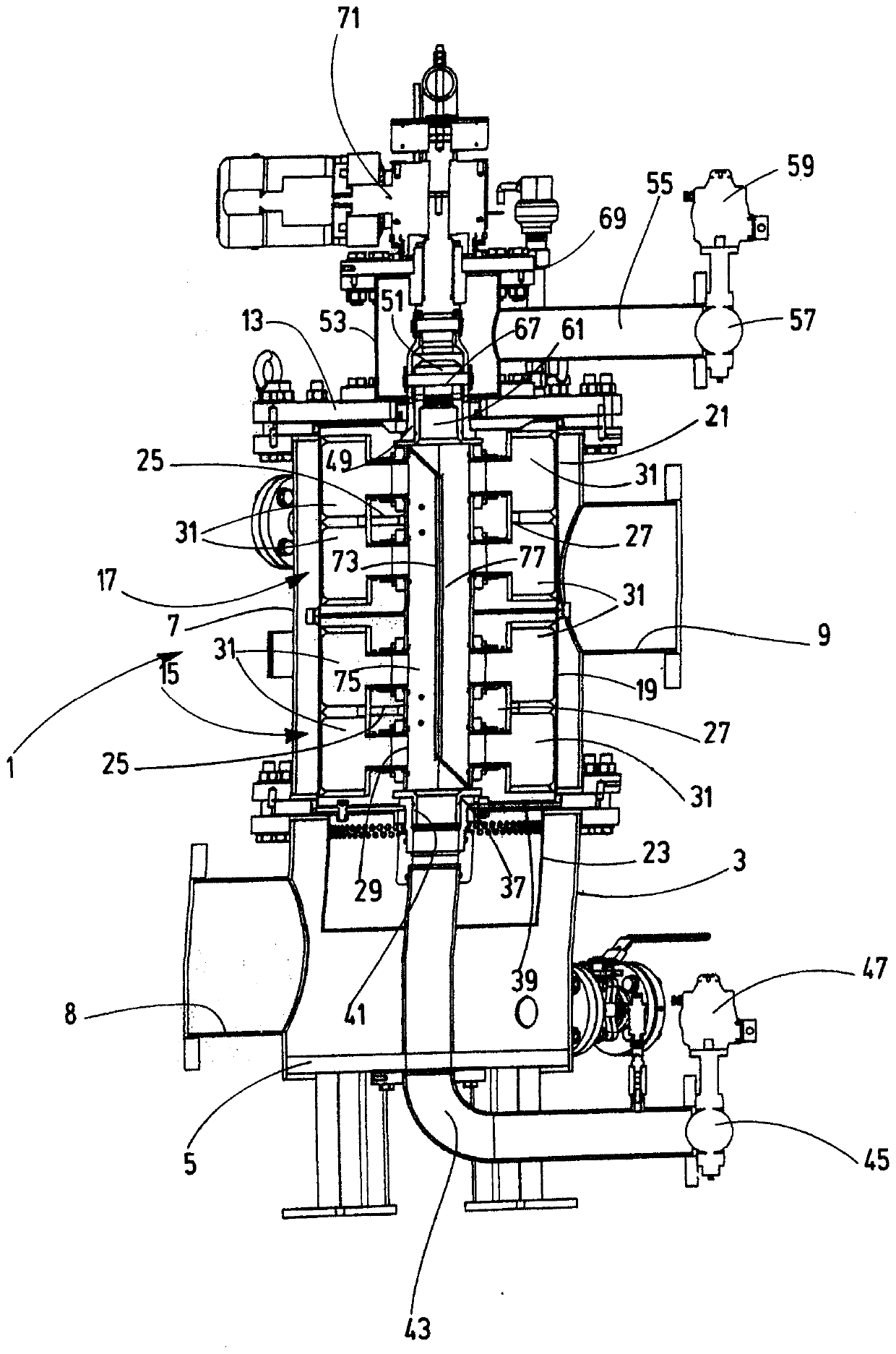

[0024] In the embodiment of the filter device according to the invention shown as a whole Figure 1 to Figure 4 In , the filter housing as a whole is marked with 1. The two-part filter housing 1 has a cylindrical inlet part 3 with a closed bottom 5 . Arranged on the input part 3 is a housing body part 7 which, like the input part 3 , is cylindrical. On the side wall of the inlet part 3 there is a fluid inlet 8 for flowing unfiltered liquid into said inlet part and a fluid outlet 9 for filtrate is located on the side wall of the body part 7 . like figure 1 As shown, on the outside of the body part 7 a switch box 11 is mounted, said switch box essentially containing an electronic filter control according to the prior art. The body part 7 is closed at the top by a cover part 13 . Received in the main part 7 are a lower filter core 15 and an upper filter core 17 whose filter screens 19 or 21 are pierced from the inside to the outside during the filtration process. flow. Unfi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com