Low temperature-resistant flexible crosslinkable halogen-free flame retardant cable material and preparation method thereof

A flame-retardant cable material, low-temperature flexible technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of a large number of toxic and harmful gases, loss of flame-retardant performance, suffocation and casualties, and avoid the deterioration of flame-retardant performance. , The effect of improving electrical insulation properties and improving dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

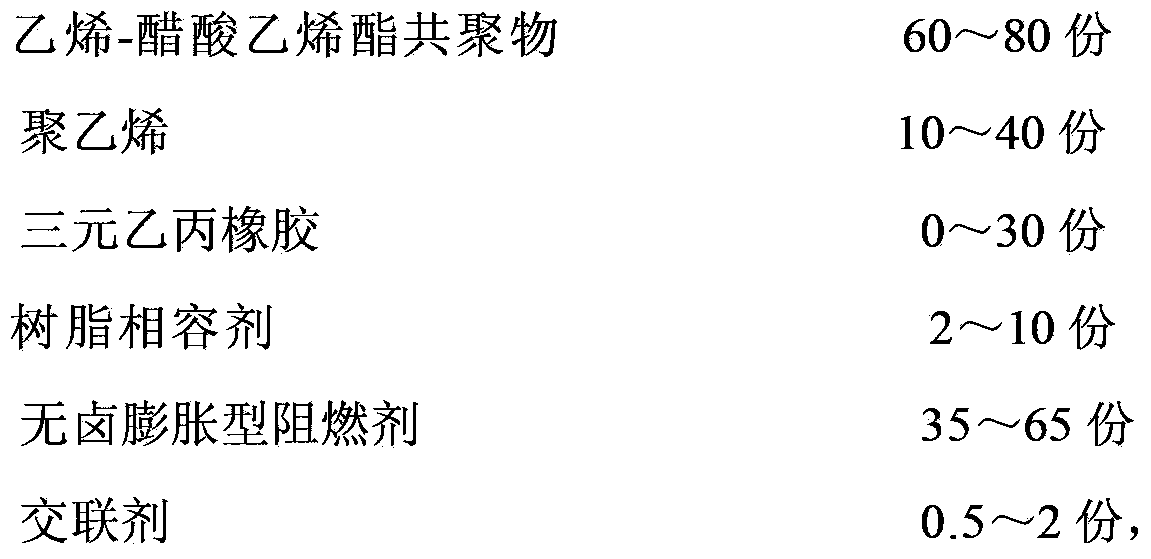

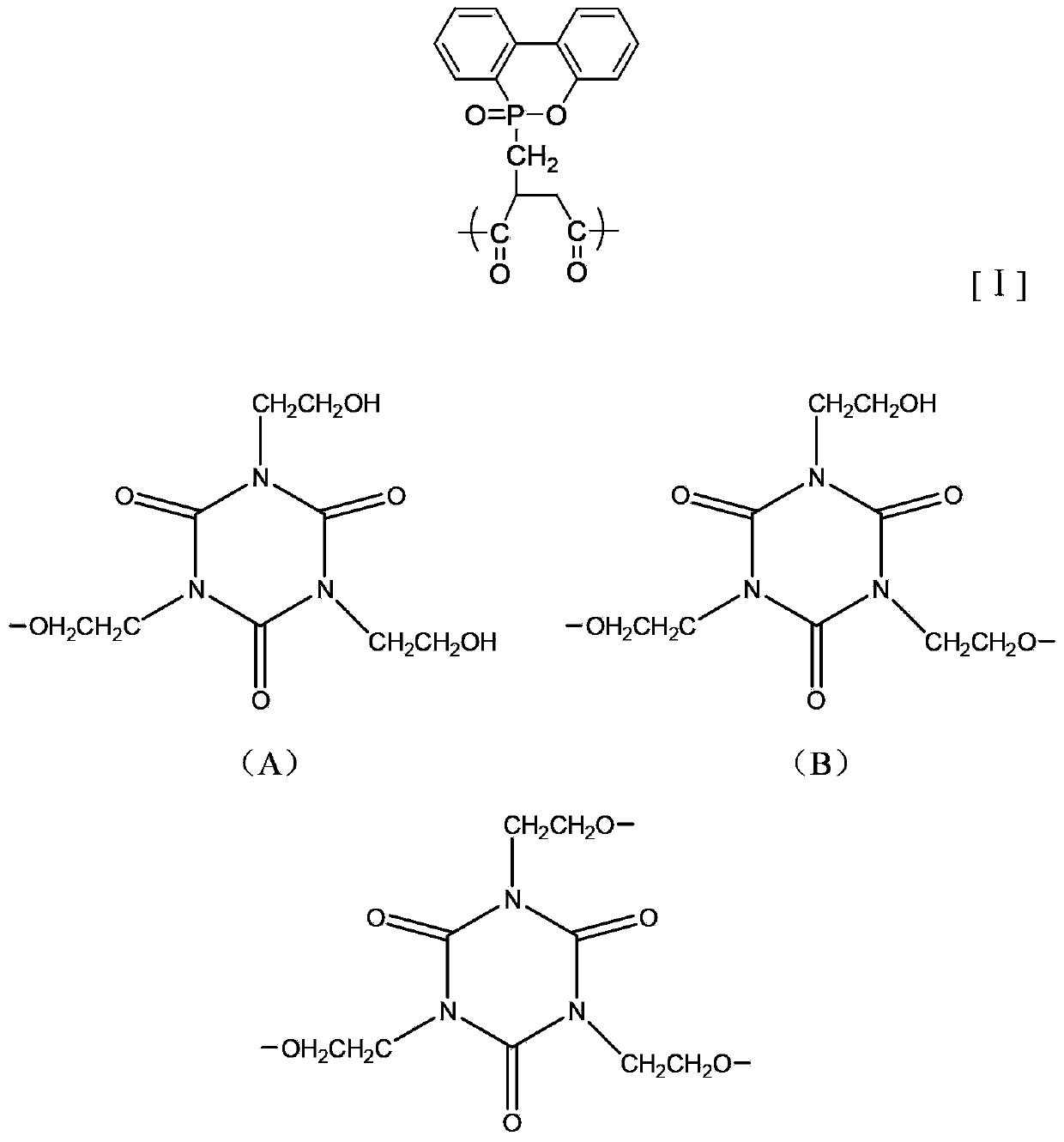

[0038] 150.4 g of 9,10-dihydro-9-oxa-10-phosphorananthrene-succinic acid, 800 g of tris(2-hydroxyethyl) isocyanurate, 288.7 g of terephthalic acid and 4.5 g of g tetrabutyl titanate was added to the reaction kettle, filled with nitrogen to remove the air in the kettle, and pressurized to 0.07MPa; under mechanical stirring, the temperature was raised to 200-240℃ within 2h to carry out esterification reaction, and the pressure in the kettle was controlled to be ≤0.1MPa , when the water generated by the esterification reaches 70ml, the esterification reaction is completed; the vacuum dehydration reaction is performed at 230-245°C for at least 0.5h, the material is discharged, pulverized and ground to pass through a 100-mesh sieve. The obtained product is a co-esterification product of char-forming agent DDP, terephthalic acid and THEIC (CFA-TTD1.41), the melting point is 110-116 °C, the initial thermal decomposition temperature is 265 °C, and the solubility in water at room temper...

Embodiment 2

[0043] 793.8 g of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-succinic acid, 1000 g of tris(2-hydroxyethyl) isocyanurate and 5 g of tetrabutyl titanate were added to the In the reaction kettle, fill with nitrogen to remove the air in the kettle, and pressurize it to 0.07MPa; under mechanical stirring, the temperature is raised to 200-240℃ within 2h to carry out the esterification reaction, and the pressure in the kettle is controlled to be ≤0.1MPa, when the water generated by the esterification is collected When it reaches 75ml, the esterification reaction is finished; the vacuum dehydration reaction is carried out at 230-245°C for at least 0.5h, the material is discharged, pulverized and ground to pass through a 100-mesh sieve. The obtained product is a co-esterified product of char-forming agent DDP and THEIC (CFA-TD1.67), with a melting point of 105-109 °C, an initial thermal decomposition temperature of 267 °C, and a solubility in water of 0.5g / 100ml at room temperature.

[...

Embodiment 3

[0048]497g of 9,10-dihydro-9-oxa-10-phosphophenanthrene-succinic acid, 1000g of tris(2-hydroxyethyl)isocyanurate, 238g of terephthalic acid and 4.5g of titanium Add tetrabutyl ester to the reaction kettle, fill the kettle with nitrogen to remove the air in the kettle, and pressurize to 0.07MPa; under mechanical stirring, the temperature is raised to 200-240°C within 2 hours to carry out the esterification reaction, and the pressure in the kettle is controlled to be ≤0.1MPa. When the water generated by the esterification reaches 95ml, the esterification reaction is over; vacuum dehydration reaction at 230-245°C for at least 0.5h, discharge, pulverize and finely pass through a 100-mesh sieve. The resulting product is the co-esterification product (CFA-TTD1.33) of char-forming agent DDP, terephthalic acid and THEIC, with a melting point of 109-113°C, an initial thermal decomposition temperature of 266°C, and a solubility in water at room temperature of 0.2 g / 100ml.

[0049] Mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com