Graphene and multiwalled carbon nanotube synergetic enhanced polymer fiber and preparation method thereof

A technology of multi-walled carbon nanotubes and graphene, which is applied in the fields of fiber chemical characteristics, melt spinning, rayon manufacturing, etc., can solve the problems of limitation, low strength and modulus of PA6, and insignificant improvement of composite fiber strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The preparation method of polyamide 6 (PA6) / graphene / multi-wall carbon nanotube fiber, comprises the steps:

[0058] 1) Utilize above-mentioned Hummers method to prepare graphite oxide;

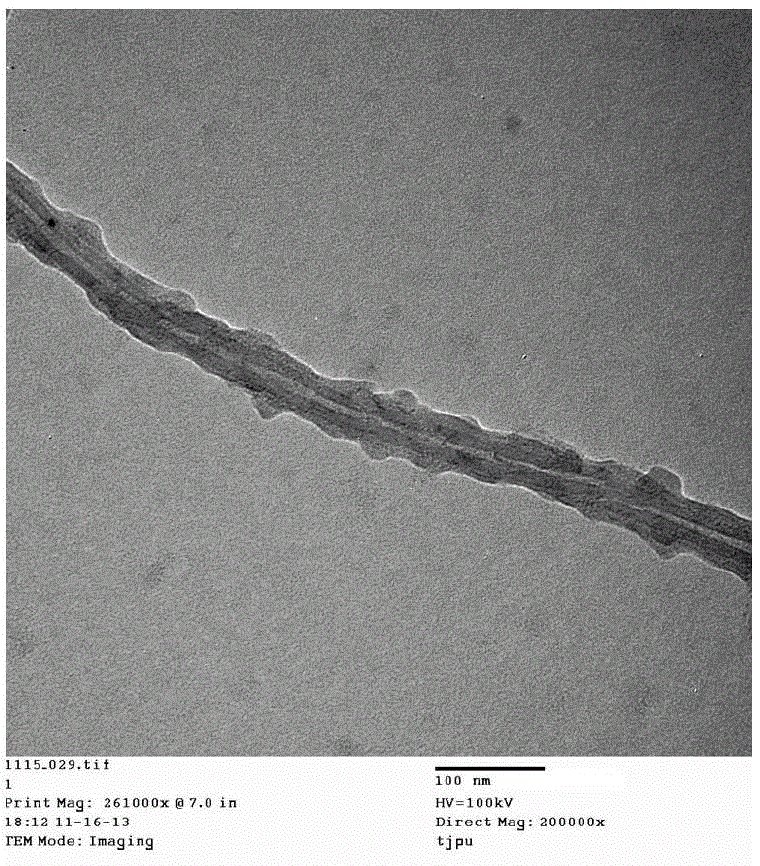

[0059] 2) Weigh 0.2g of the graphite oxide prepared in step 1), ultrasonically disperse it in 50ml of toluene, then add 2g of maleic anhydride, react for 5h under a nitrogen atmosphere at 40°C, and then add 0.16g of azobis Isobutyronitrile, 2g of styrene and 2g of maleic anhydride were copolymerized at 80°C for 2h to obtain a black solid, which was ultrasonically washed 3 times with acetone, centrifuged and then vacuum-dried at 80°C for 24h to obtain styrene -Maleic anhydride copolymer grafted functionalized graphene (such as Figure 1a shown);

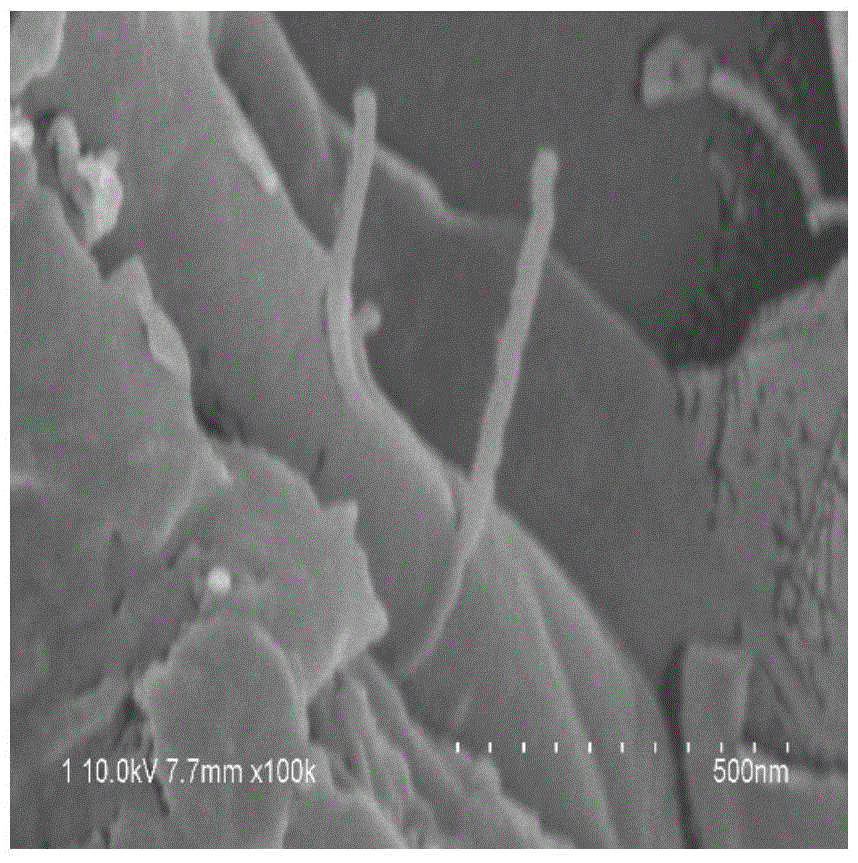

[0060] 3) Ultrasonic disperse 0.3g of hydroxylated carbon nanotubes in 70ml of toluene, add 3g of maleic anhydride, react for 5h under nitrogen atmosphere, 40°C, stirring conditions, then add 0.24g of azobisisobutyronitrile, 3g of styrene an...

Embodiment 2

[0068] 1) Utilize above-mentioned Hummers method to prepare graphite oxide;

[0069] 2) Weigh 0.2g of the graphite oxide prepared in step 1), ultrasonically disperse it in 50ml of toluene, then add 2g of maleic anhydride, react for 5h under a nitrogen atmosphere at 40°C, and then add 0.16g of azobis Isobutyronitrile, 2g styrene, 2g maleic anhydride, copolymerized at 80°C for 2h to obtain a black solid, the black solid was ultrasonically washed 3 times with acetone, centrifuged and then vacuum dried at 80°C for 24h to obtain styrene - functionalized graphene grafted with maleic anhydride copolymer;

[0070] 3) Ultrasonic disperse 0.3g of hydroxylated carbon nanotubes in 70ml of toluene, add 3g of maleic anhydride, react for 5h under nitrogen atmosphere, 40°C, and stir, add 0.24g of azobisisobutyronitrile and 3g of styrene respectively , copolymerization reaction at 80°C for 2h to obtain a black solid, which was ultrasonically washed 3 times with acetone, centrifuged and then v...

Embodiment 3

[0076] 1) Utilize above-mentioned Hummers method to prepare graphite oxide;

[0077] 2) Weigh 0.2g of the graphite oxide prepared in step 1), ultrasonically disperse it in 50ml of toluene, then add 2g of maleic anhydride, react for 5h under a nitrogen atmosphere at 40°C, and then add 0.16g of azobis Isobutyronitrile, 2g styrene, 2g maleic anhydride, copolymerized at 80°C for 2h to obtain a black solid, the black solid was ultrasonically washed 3 times with acetone, centrifuged and then vacuum dried at 80°C for 24h to obtain styrene - functionalized graphene grafted with maleic anhydride copolymer;

[0078] 3) Ultrasonic disperse 0.3g of hydroxylated carbon nanotubes in 70ml of toluene, add 3g of maleic anhydride, react for 5h under nitrogen atmosphere, 40°C, and stir, add 0.24g of azobisisobutyronitrile and 3g of styrene respectively , copolymerization reaction at 80°C for 2h to obtain a black solid, which was ultrasonically washed 3 times with acetone, centrifuged and then v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com