Carbon nanotube paste for lithium battery and preparation method for carbon nanotube paste

A carbon nanotube and lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of carbon nanotubes being difficult to disperse, and achieve the effects of improving electrical conductivity, good mixing effect, and improved dispersion degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

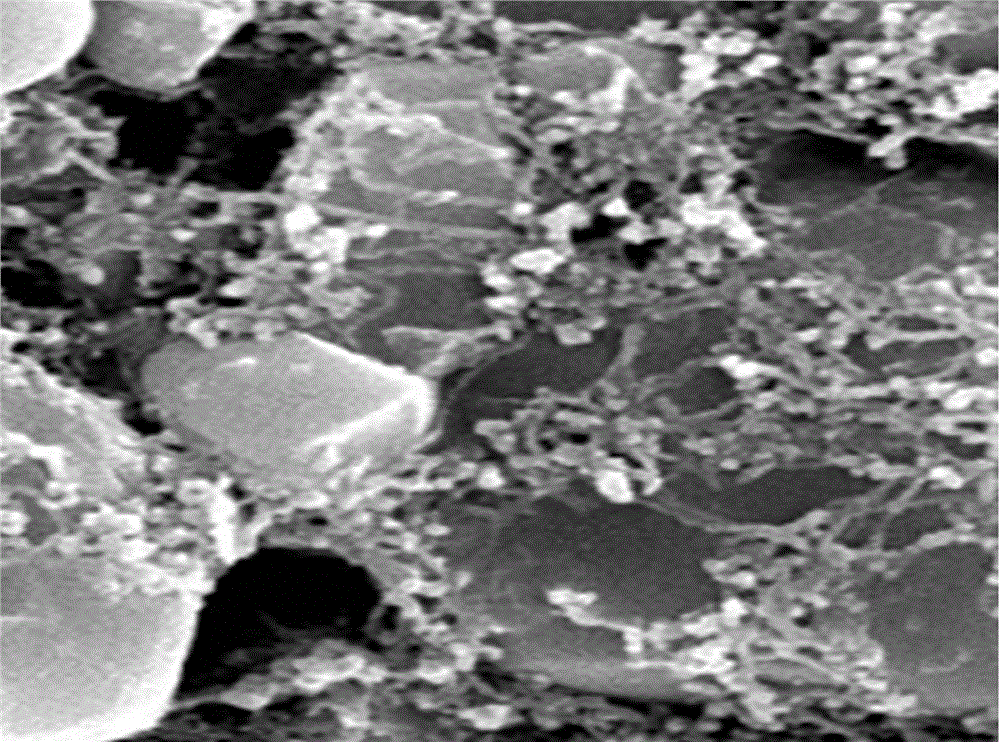

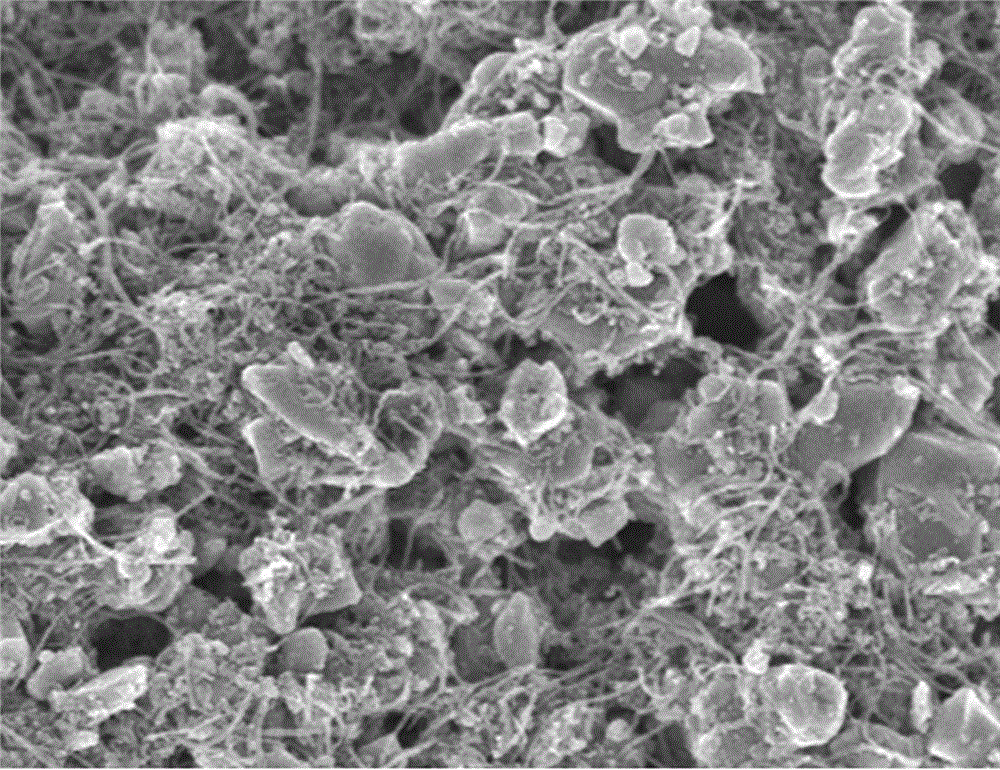

Image

Examples

Embodiment 1

[0019] Taking the oily carbon nanotube slurry and its preparation method as an example, its formula and steps are as follows.

[0020] A carbon nanotube slurry for lithium batteries, the formula used is: carbon nanotube: carbon black: polyvinylpyrrolidone: nitrogen methylpyrrolidone = 6wt%: 3wt%: 1.2wt%: 89.8wt%. Among them, the diameter of carbon nanotubes is 7~15nm, the length is 6~15μm, and the specific surface area is 260m 2 / g. Carbon black particle size is 30~50nm, specific surface area is 60m 2 / g.

[0021] The mixing and stirring process includes dry powder premixing, solution preparation, slurry premixing and stirring, and mixing mode circulation stirring. The specific steps are as follows:

[0022] (1) Dry powder premixing: weigh carbon nanotubes and carbon black to 6Kg and 3Kg respectively, and then premix in a powder mixer for 40 minutes;

[0023] (2) Solution preparation: weigh the surfactant polyvinylpyrrolidone to 1.2Kg, add it into the solvent after weighin...

Embodiment 2

[0028] Taking the water-based carbon nanotube slurry and its preparation method as an example, its formula and steps are as follows.

[0029] The formula used is: carbon nanotube: carbon black: polyacrylate copolymer: sodium carboxymethyl cellulose: deionized water=3wt%: 1wt%: 0.5wt%: 0.2wt%: 95.3wt%. Among them, the diameter of carbon nanotubes is 12~25nm, the length is 13~25μm, and the specific surface area is 160m 2 / g. Carbon black particle size is 40~60nm, specific surface area is 40m 2 / g.

[0030] The mixing and stirring process includes dry powder premixing, solution preparation, slurry premixing and stirring, and mixing mode circulation stirring. The specific steps are as follows:

[0031] (1) Dry powder premixing: weigh carbon nanotubes and carbon black to 3Kg and 1Kg respectively, and then premix in a powder mixer for 30 minutes;

[0032] (2) Solution preparation: weigh the surfactant polyvinylpyrrolidone and the thickener sodium carboxymethyl cellulose, the mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com