Preparation method for silver powder

A kind of silver powder, contact preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

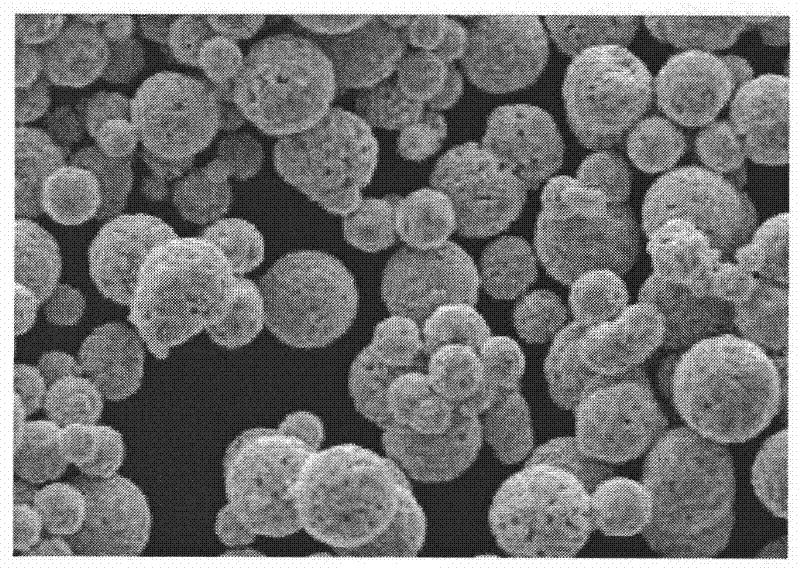

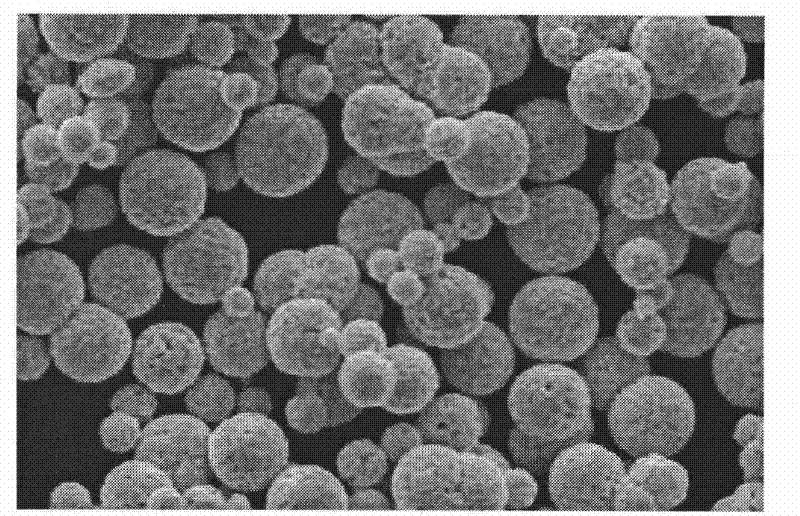

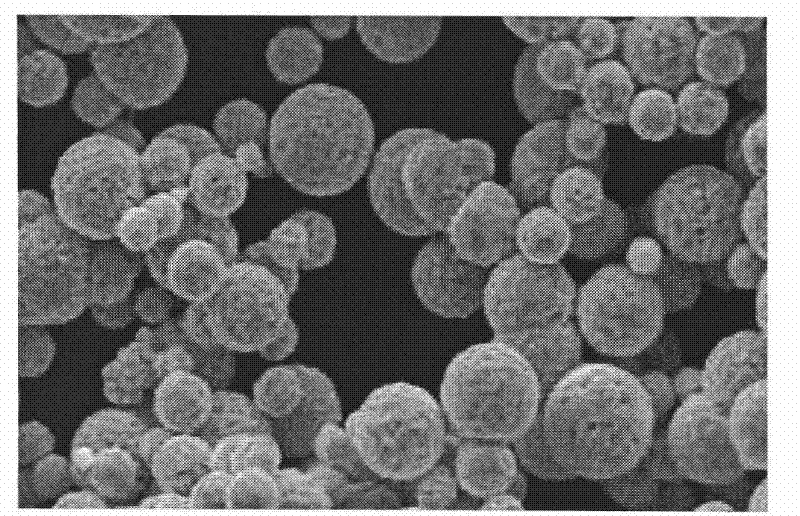

Image

Examples

preparation example Construction

[0039] The preparation method of silver powder of the present invention is based on 100 parts of the quality of silver nitrate, specifically can comprise the following steps:

[0040] a. Preparation of silver nitrate solution:

[0041] Silver nitrate 100

[0042]Deionized water 600-1000

[0043] Dispersant 1.0-10

[0044] Thickener 0.5-6

[0045] The above-mentioned substances are mixed and stirred until completely dissolved according to their corresponding parts by weight;

[0046] b. Preparation of reducing agent solution:

[0047] Deionized water 100-300

[0048] Dispersant 1.0-10

[0049] Thickener 0.5-6

[0050] Neutralizer 10-80

[0051] Strong reducing agent 0.1-5

[0052] Medium strong reducing agent or medium reducing agent 1-95

[0053] Weak reducing agent 5-200

[0054] Prepare reducing agent solution by above-mentioned each material and corresponding weight portion thereof;

[0055] c. Preparation of silver powder:

[0056] Heat 1000 parts by mass of t...

Embodiment 1

[0059] a. Preparation of silver nitrate solution

[0060] 60g of silver nitrate, 1000g of deionized water, 2.5g of polyvinylpyrrolidone, and 2g of hydroxymethylcellulose were mixed and stirred until completely dissolved.

[0061] b. Preparation of reducing agent solution

[0062] Mix and stir 0.06 g of hydrazine hydrate (88%) solution, 200 g of deionized water, 13.5 g of ascorbic acid, 20 g of glucose, 0.5 g of polyvinylpyrrolidone, 2 g of hydroxymethyl cellulose, and 24 g of 25% concentrated ammonia water until completely dissolved.

[0063] c. Preparation of silver powder

[0064] Heat the silver nitrate solution prepared in a to a constant temperature of 72°C in a water bath, and stir at a speed of 500r / min, then drop the reducing agent solution prepared in b into the silver nitrate solution at a speed of 5ml / min, Continue to stir for 5 minutes after dripping, take it out, let it stand, cool, precipitate, and age. Pour off the supernatant liquid, wash the silver powder t...

Embodiment 2

[0067] a. Preparation of silver nitrate solution

[0068] Silver nitrate 60g, deionized water 1000g, polyethylene glycol 400 (PEG) 5g, carboxymethyl starch sodium 3g, mix and stir until completely dissolved.

[0069] b. Preparation of reducing agent solution

[0070] Hydrazine hydrate (88%) solution 0.06g, deionized water 200g, formaldehyde (37%) 0.36g, polyethylene glycol 400 (PEG) 1.25g, sodium carboxymethyl starch 3g, glucose 20g, ammonium bicarbonate ( AR) 26.7g, mixed and stirred until completely dissolved.

[0071] c. Preparation of silver powder

[0072] Heat the silver nitrate solution prepared in a to a constant temperature of 70°C in a water bath, and stir at a speed of 300r / min, then drop the reducing agent solution prepared in b into the silver nitrate solution at a speed of 4ml / min, Continue to stir for 5 minutes after dripping, take it out, let it stand, cool, precipitate, and age. Pour off the supernatant liquid, wash the silver powder twice with alcohol and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com