PLA/PBAT biodegradable composite material and preparation method thereof

A composite material and biodegradable technology, which is applied in the field of PLA/PBAT biodegradable composite materials and its preparation, can solve problems such as poor compatibility, and achieve the effects of improved toughness, excellent tensile strength, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

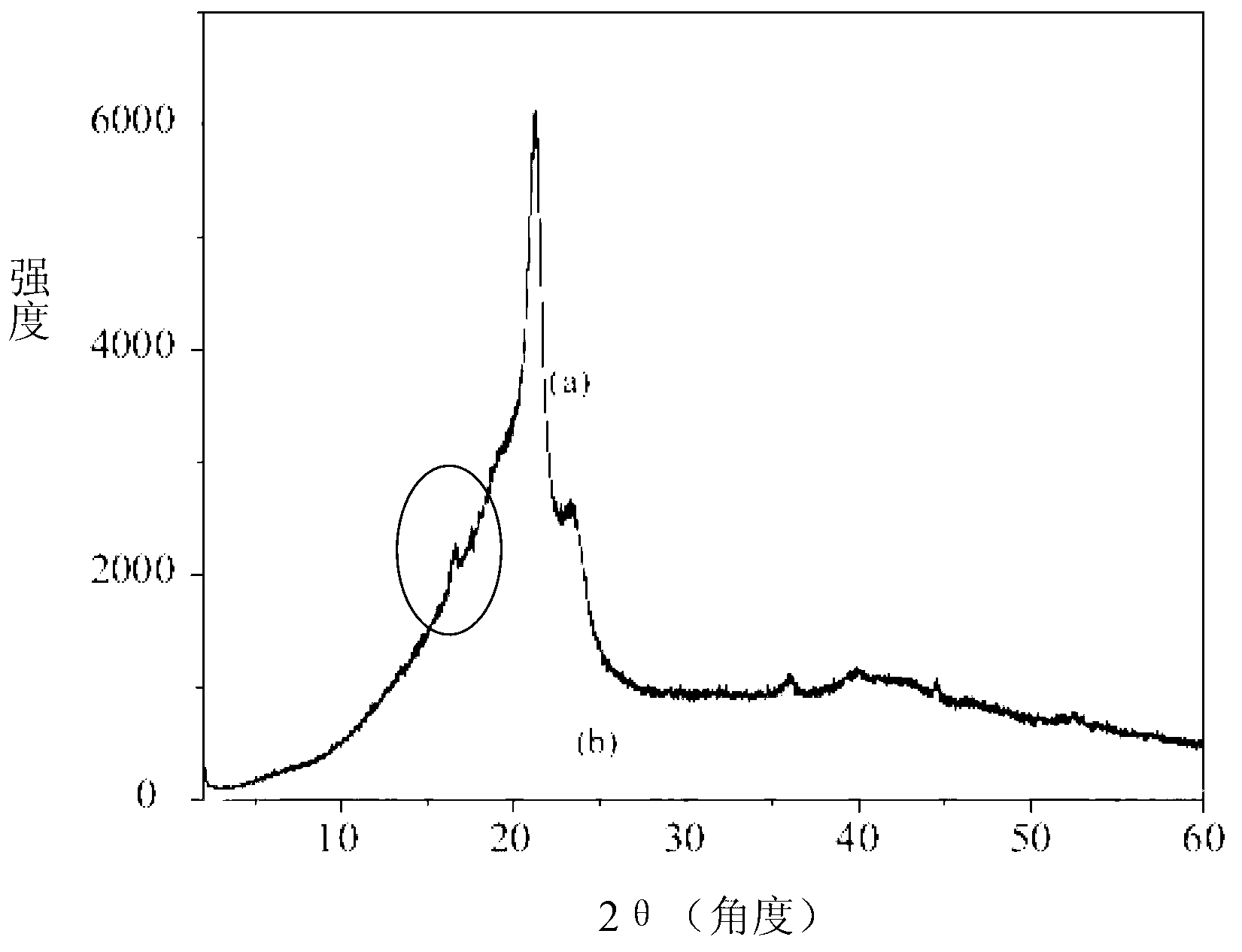

Image

Examples

Embodiment 1

[0057] In the torque rheometer (Hacke, Germany), add 60g EVA (Escorene Ultra Lot.61E466, Exxon Mobil, the content of vinyl acetate (mass fraction) is 27%), the temperature is 160 ℃, two rotors The direction of rotation of the two rotors is opposite, the speed of the two rotors is 40 rpm, and the heating is maintained for 40 minutes. Then turn on the torque rheometer, and add the catalyst Ti(OPr) with a mass of 2g 4 and polylactic acid with a mass of 40g (Natureworks2002D, LD mixed polylactic acid). Under the original temperature conditions, continue heating for 30 minutes, that is, react at 160 ° C for 30 minutes, add the obtained product into 120 mL of acetone, then filter to obtain the undissolved product, and then add it into 60 mL of hot toluene ( 80°C), the crude graft copolymer was obtained by filtration, and finally washed with methanol, placed in a vacuum drying oven at a temperature of 90°C, and dried for 20 minutes to obtain an EVA-PLA grafted copolymer with a PLA m...

Embodiment 2~12

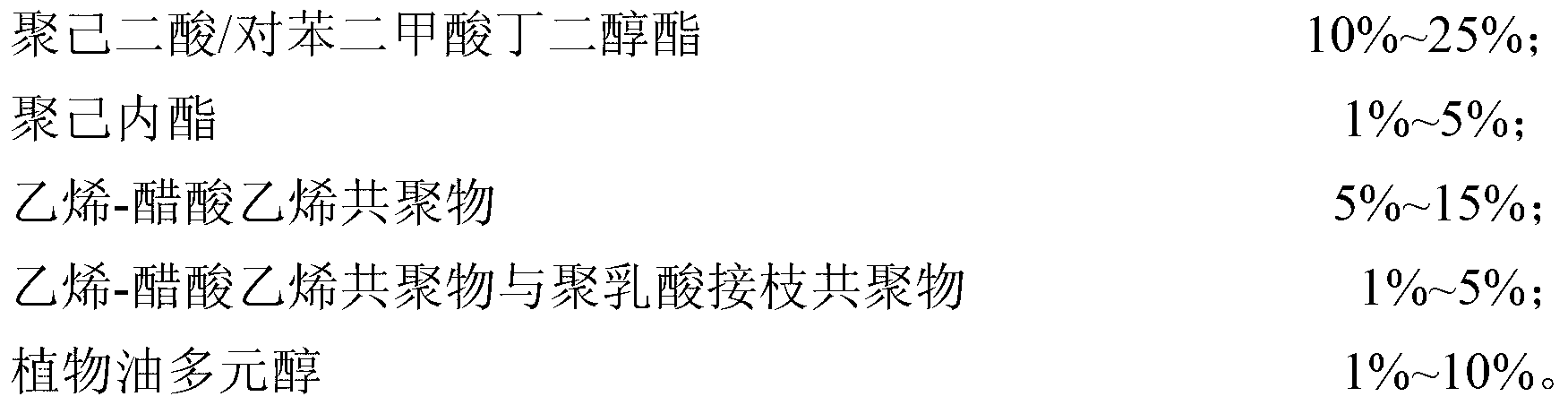

[0061] The PLA / PBAT biodegradable composite material adopts the following raw materials in weight percentage:

[0062]

[0063] Among them, polylactic acid adopts Natureworks2002D, LD mixed type polylactic acid; polyadipate / butylene terephthalate adopts the product produced by BASF company Polycaprolactone adopts the product produced by Belgian Solvay Caprolactones company, and its weight average molecular weight is 68000; %). Vegetable oil polyols can adopt commercially available products.

[0064] Mix polylactic acid, polyadipate / butylene terephthalate, polycaprolactone, ethylene-vinyl acetate copolymer, ethylene-vinyl acetate copolymer with polylactic acid graft copolymer and vegetable oil polyol, The mixed material is fed into a twin-screw extruder for melt blending, then drawn into strands and pelletized to obtain a PLA / PBAT biodegradable composite material.

[0065] The temperature of melt blending is 160°C, 165°C, 165°C, 170°C, 170°C, 165°C, 165°C, 160°C in each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com