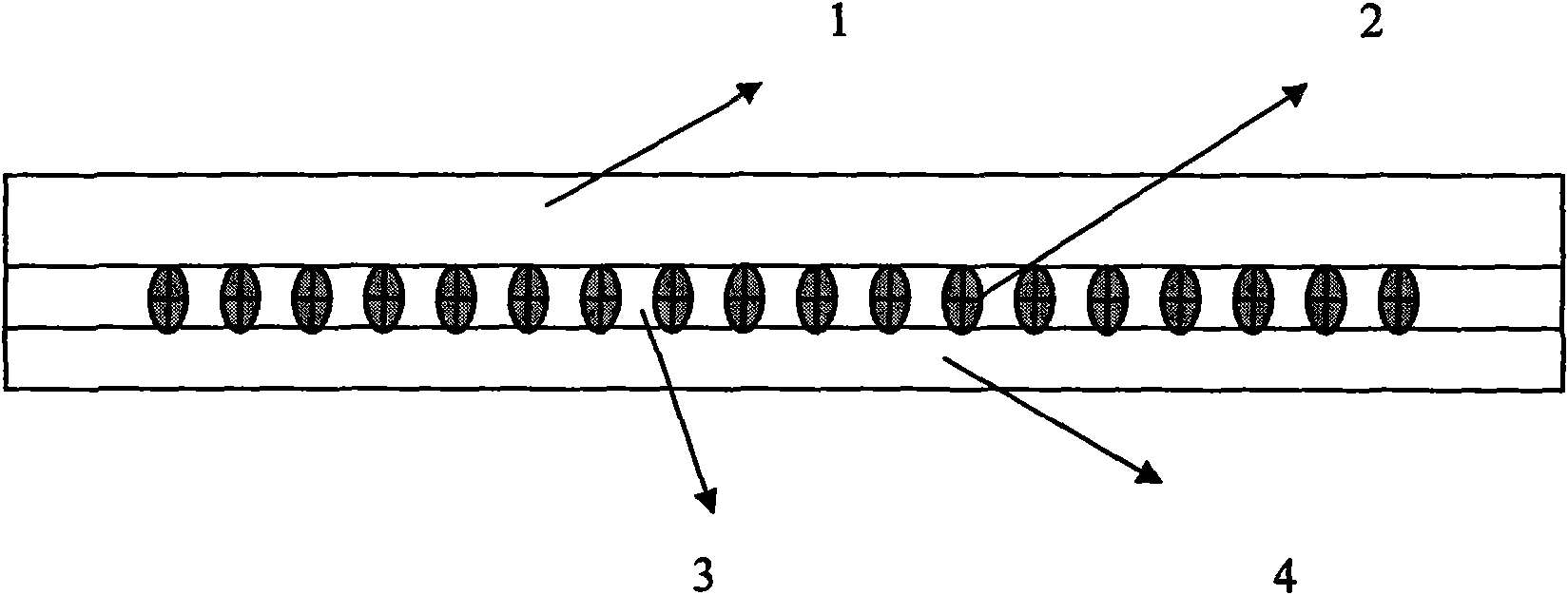

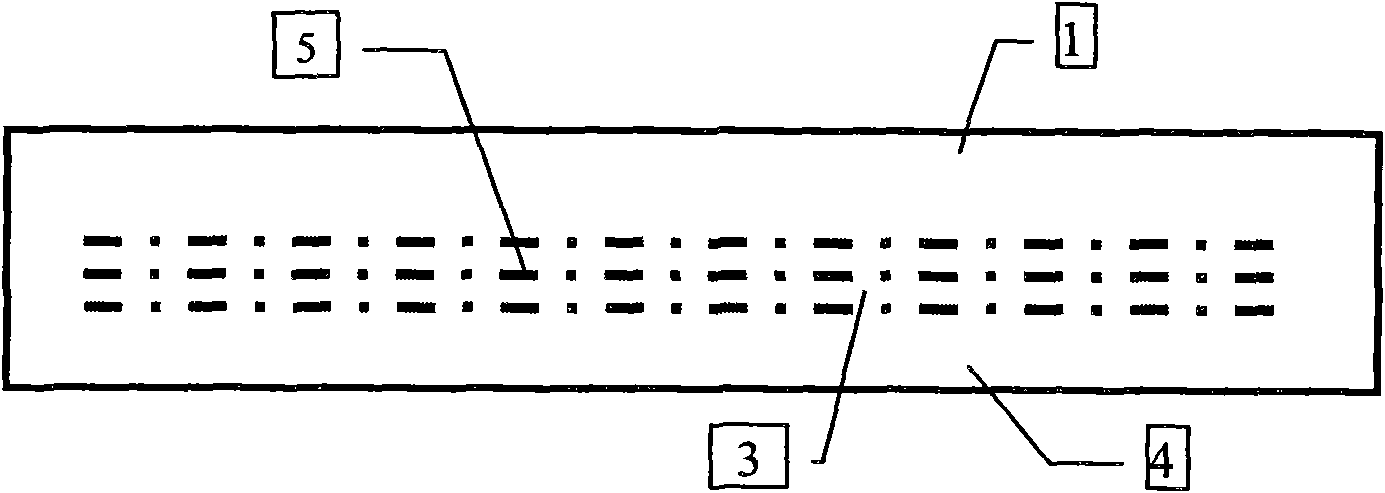

Oilproof flame retardant conveyor belt

A conveyor belt, flame-retardant technology, applied in the field of conveying materials, can solve problems such as short service life, failure to meet safety production indicators, shedding, etc., and achieve improved dispersion, improved flame retardancy, oil resistance and improved flame retardancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

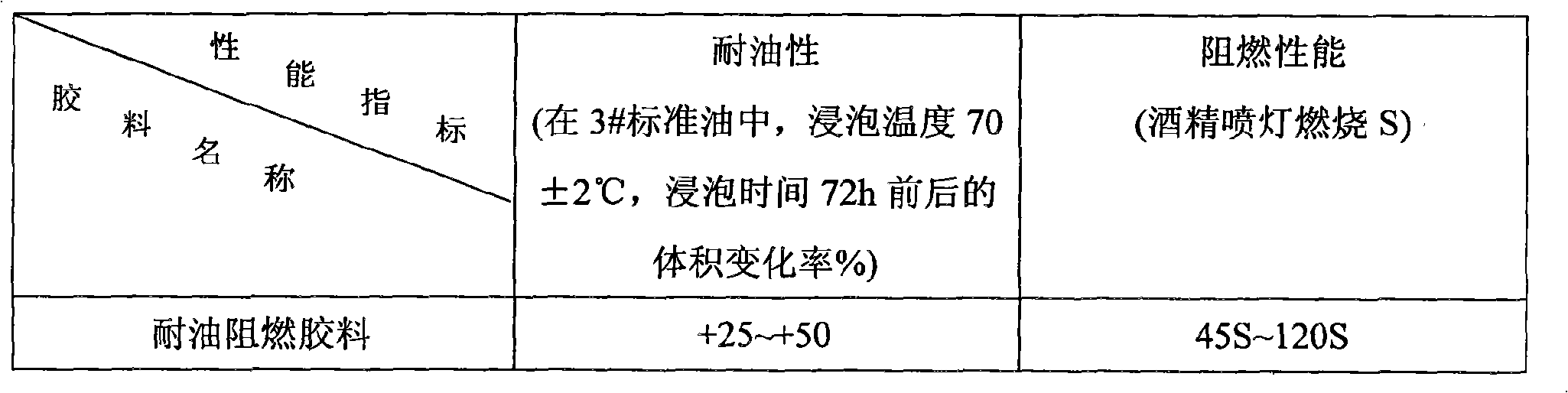

Examples

Embodiment 1

[0029] 20 parts of chloroprene rubber, 80 parts of nitrile rubber containing 35% (mass) acrylic hydrocarbon, 15 parts of chlorinated polyethylene, 50 parts of composite flame retardant (the quality of antimony trioxide: the quality of zinc borate: hydroxide The quality of aluminum: the quality of liquid bromine = 1:3:6:5), 3 parts of n-octanoic acid, 1.5 parts of methyl n-octanoate, 0.5 parts of potassium stearate, 3 parts of zinc oxide, 1 part of stearic acid, accelerator 1 part of CBS, 0.5 parts of accelerator TMTD, 1 part of antioxidant RD, 1 part of antioxidant 4020, 1 part of antioxidant 4010NA, 50 parts of carbon black, 3.0 parts of sulfur.

Embodiment 2

[0031] 40 parts of chloroprene rubber, 60 parts of nitrile rubber containing 40% (mass) acrylic hydrocarbon, 20 parts of chlorinated polyethylene, 70 parts of composite flame retardant (the quality of antimony trioxide: the quality of zinc borate: hydroxide The quality of aluminum: the quality of liquid bromine = 1:3:6:5), 2 parts of palmitic acid, 0.7 parts of methyl palmitate, 0.3 parts of potassium palm oil fatty acid, 5 parts of zinc oxide, 2 parts of stearic acid, accelerator 0.5 parts of CBS, 0.5 parts of accelerator TMTD, 1 part of antioxidant RD, 2 parts of antioxidant 4020, 40 parts of carbon black, and 2.0 parts of sulfur.

Embodiment 3

[0033] 30 parts of chloroprene rubber, 70 parts of nitrile rubber containing 35% (mass) acrylic hydrocarbon, 18 parts of chlorinated polyethylene, 4 parts of antimony trioxide, 12 parts of zinc borate, 24 parts of aluminum hydroxide, 20 parts of liquid bromine , 2.5 parts of lauric acid, 1 part of glyceryl laurate, 0.5 parts of sodium stearate, 4 parts of zinc oxide, 1.5 parts of stearic acid, 0.8 parts of accelerator CBS, 0.4 parts of accelerator TMTD, 1.5 parts of anti-aging agent RD, anti-aging Agent 4010NA 2.5 parts, carbon black 30 parts, sulfur 2.5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com