Boron and nitrogen co-doping chitosan-base activated carbon and method for preparing same

A technology of chitosan and activated carbon, applied in the direction of chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of environmental pollution, increase of production cost, waste of water resources, etc., achieve simple preparation process, avoid high cost, Concentrated effect of pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

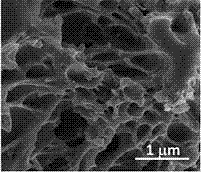

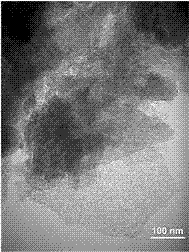

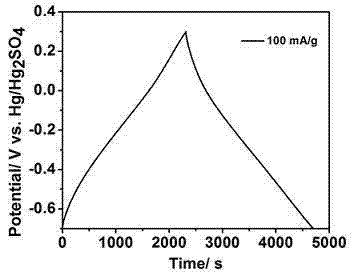

[0025] 1. A boron-nitrogen co-doped chitosan-based activated carbon, with chitosan and boric acid as raw materials, prepared according to the following preparation method: add 4 mL of deionized water to 2 g of chitosan, stir for 5 minutes, Then 1 mL of 1 mol / L hydrochloric acid was added dropwise and stirred for 10 minutes. Protonated chitosan was added to 11 g of boric acid aqueous solution with a mass concentration of 5%, and the temperature of the boric acid solution used was 60 °C, and stirred for 30 minutes. The obtained mixture was placed in a horizontal carbonization furnace, raised from room temperature to 700 °C at a heating rate of 5 °C / min under a nitrogen atmosphere, kept at a constant temperature for 1 hour, and then naturally cooled to room temperature. The carbonized product was ground into powder, passed through a 300-mesh sieve, then boiled in deionized water for 90 minutes, filtered with suction, the filter cake was rinsed 3 times with deionized water, and th...

Embodiment 2

[0029] 1. A boron-nitrogen co-doped chitosan-based activated carbon, with chitosan and boric acid as raw materials, prepared according to the following preparation method: add 4 mL of deionized water to 2 g of chitosan, stir for 5 minutes, Then 1 mL of 1 mol / L hydrochloric acid was added dropwise, and the protonated chitosan was added to 11 g of boric acid aqueous solution with a mass concentration of 9.09%. The temperature of the boric acid solution used was 60-90°C and stirred for 30 minutes. The resulting mixture was placed in a horizontal carbonization furnace, raised from room temperature to 800 °C at a heating rate of 5 °C / min under a nitrogen atmosphere, kept at a constant temperature for 1 hour, and then naturally cooled to room temperature. Grind the carbonized product into powder, sieve through a 300-mesh sieve, boil in deionized water for 90 minutes, then filter with suction, rinse the filter cake with deionized water for 3 times, and dry the filter cake in a vacuum ...

Embodiment 3

[0033] 1. A boron-nitrogen co-doped chitosan-based activated carbon, with chitosan and boric acid as raw materials, prepared by the following preparation method: add 10 mL of deionized water to 2 g of chitosan, stir for 5 minutes, Then 1 mL of 1 mol / L hydrochloric acid was added dropwise, and stirred for 5 min. The protonated chitosan was added to 11 g of boric acid aqueous solution with a mass concentration of 15%, and the temperature of the boric acid solution used was 60-90°C and stirred for 30 minutes. The resulting mixture was placed in a horizontal carbonization furnace, raised from room temperature to 900 °C at a heating rate of 5 °C / min under a nitrogen atmosphere, kept at a constant temperature for 1 hour, and then naturally cooled to room temperature. The carbonized product was ground into powder, passed through a 300-mesh sieve, then boiled in deionized water for 90 minutes, then suction filtered, the filter cake was rinsed 3 times with deionized water, and the filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com