Production method and device of fine-grained low-chloride rare earth carbonate

A technology of rare earth carbonate and production method, applied in rare earth metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as affecting the recovery rate of rare earth, pollute the environment, etc., and achieve the effect of continuous production and less washing water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

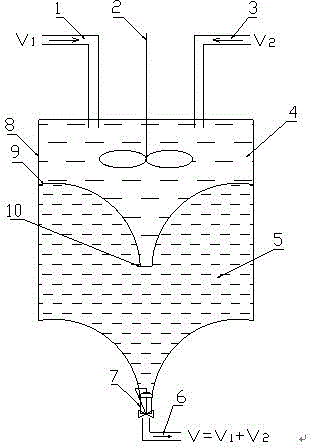

Image

Examples

Embodiment 1

[0029] Take 200 mL of pure water and place it in the precipitation reaction device. At the same time, add 5 g of lanthanum carbonate to the pure water as a seed crystal, heat the solution in the reaction device to a constant temperature of 50 °C, and add lanthanum chloride material with a concentration of 40 g / L Both the ammonium bicarbonate solution and the ammonium bicarbonate solution with a concentration of 80 g / L were simultaneously fed in parallel at a feeding rate of 6 mL / min. After stirring the reaction system for 20 min, the valve at the bottom of the reaction device was opened to allow the suspension to Discharge at a discharge rate of 12 mL / min, filter, and wash with normal temperature water until the filtrate does not become turbid in contact with the silver nitrate solution, and the obtained solid is a fine-grained low-chloride lanthanum carbonate product. The total amount of rare earth in the lanthanum carbonate product is 50.31%, the chloride radical contained in...

Embodiment 2

[0031] Take 200 mL of pure water and place it in the precipitation reaction device, add 5 g of cerium carbonate as a seed crystal to the pure water at the same time, heat the solution temperature in the reaction device to a constant temperature of 60 °C, and transfer the cerium chloride material with a concentration of 60 g / L The ammonium bicarbonate solution and the ammonium bicarbonate solution with a concentration of 80 g / L were fed in parallel flow at the feeding speed of 5 mL / min and 3 mL / min respectively. After stirring the reaction system for 30 min, the valve at the bottom of the reaction device was opened. The suspension was discharged at a discharge rate of 8 mL / min, filtered, and washed with normal temperature water until the filtrate contacted with the silver nitrate solution did not produce turbidity, and the obtained solid was a fine-grained low-chloride cerium carbonate product. The total amount of rare earth in the cerium carbonate product is 51.12%, the chlorid...

Embodiment 3

[0033] Take 200 mL of pure water and place it in the precipitation reaction device. At the same time, add 5 g of yttrium carbonate to the pure water as a seed crystal, heat the solution in the reaction device to a constant temperature of 60 °C, and transfer the yttrium chloride material with a concentration of 60 g / L to The ammonium bicarbonate solution and the ammonium bicarbonate solution with a concentration of 100 g / L were simultaneously fed in a co-current manner at a feeding rate of 6 mL / min and 3 mL / min, respectively. After stirring the reaction system for 30 min, the valve at the bottom of the reaction device was opened. The suspension was discharged at a discharge rate of 9 mL / min, filtered, and washed with normal temperature water until the filtrate contacted with the silver nitrate solution did not produce turbidity, and the obtained solid was fine-grained and low-impurity yttrium carbonate product. The total amount of rare earths in the yttrium carbonate product is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com