Composite photocatalyst for degrading pesticide residues

A photocatalyst and composite technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as easy agglomeration and unstable anatase, and achieve uniform dispersion and crystal grain The effect of controllable components and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

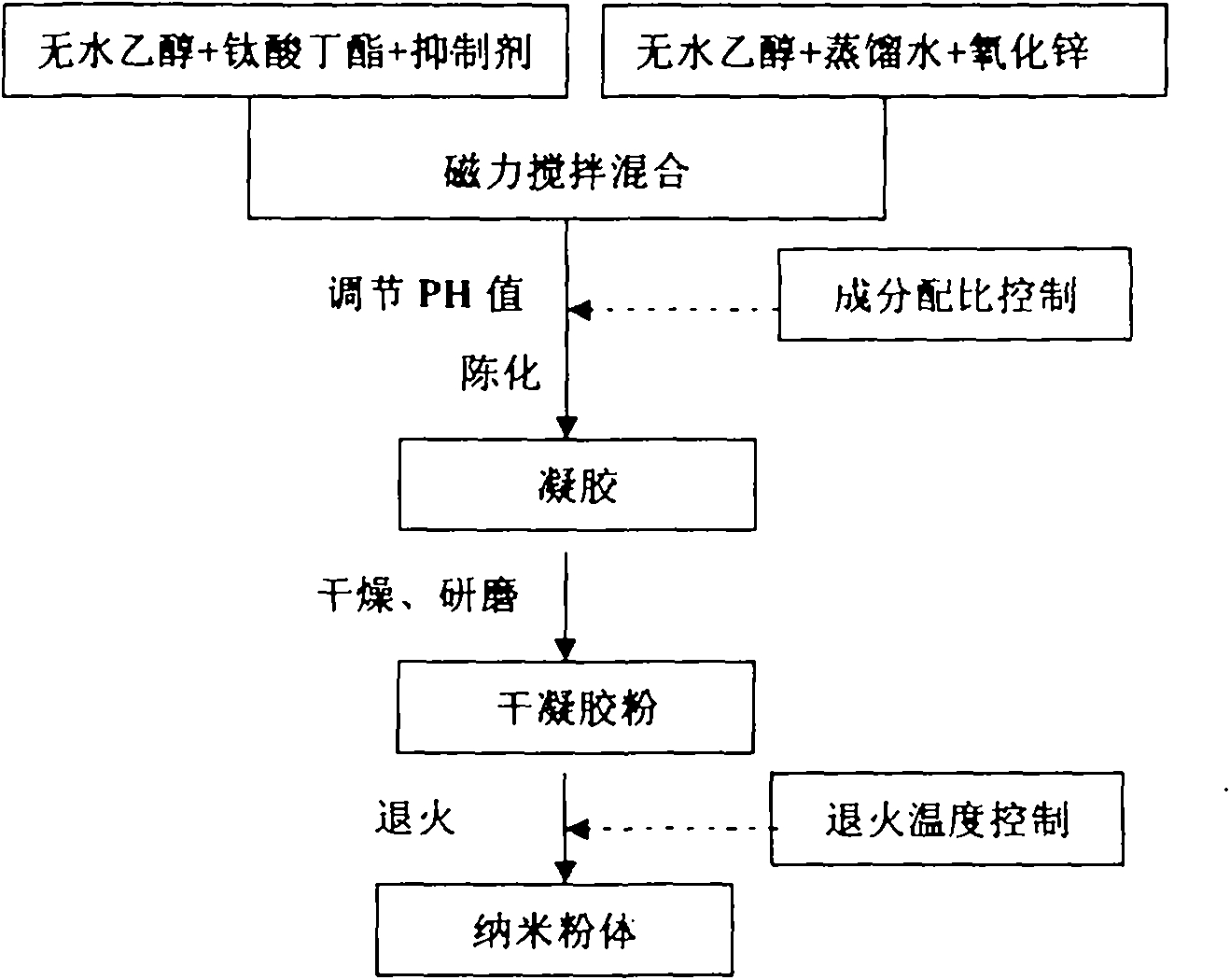

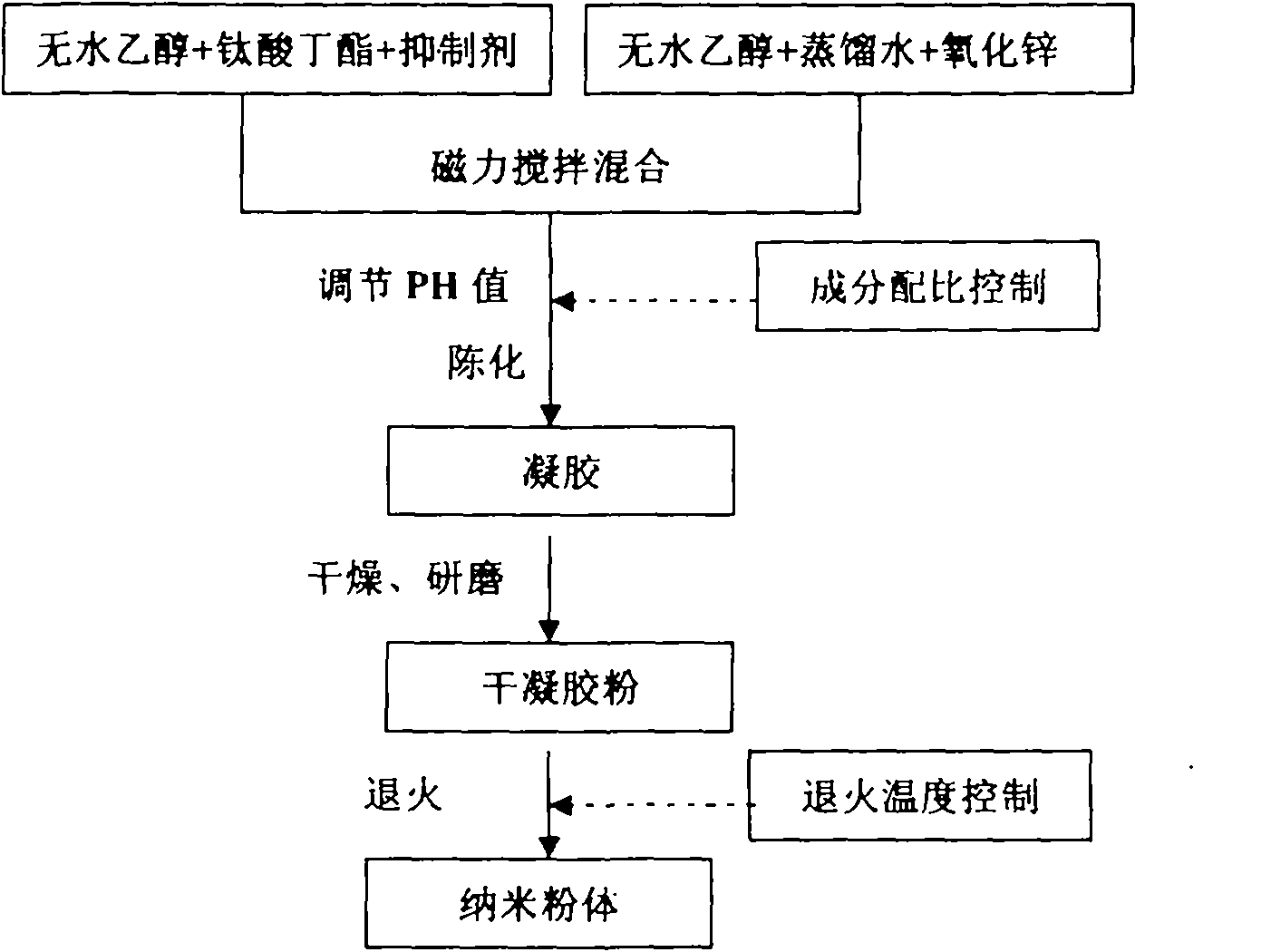

Method used

Image

Examples

Embodiment 1

[0019] Measure 10ml of tetrabutyl titanate, add 300ml of absolute ethanol to make a solution, drop 3-4 drops of glacial acetic acid at a stirring speed of 150r / min, and magnetically stir for 30min at room temperature to fully mix the solution to obtain A solution. At the same time, another 1 ml of distilled water and 200 ml of absolute ethanol were taken, and ZnO with a molar ratio of tetrabutyl titanate of 8:1 was added for compounding, and magnetically stirred for 30 minutes to obtain solution B. Slowly add the obtained B solution to A solution, add concentrated hydrochloric acid to adjust the pH to 3, and stir for 30 minutes to obtain stable, uniform, clear and transparent TiO 2 / ZnO sol. Put the sol into a vacuum drying oven and dry it at 80°C to form a xerogel. The xerogel was ground with an agate mortar to obtain a powder. Put the powder into a muffle furnace and heat-treat at 600°C to obtain nano-TiO 2 / ZnO powder. Then the obtained nano-TiO 2 / ZnO powder is hydro...

Embodiment 2

[0021] Measure 20ml of tetrabutyl titanate, add 300ml of absolute ethanol to make a solution, drop 3-4 drops of glacial acetic acid at a stirring speed of 150r / min, and magnetically stir for 30min at room temperature to fully mix the solution to obtain A solution. At the same time, another 1 ml of distilled water and 200 ml of absolute ethanol were taken, and ZnO compounded with tetrabutyl titanate at a molar ratio of 4:1 was added, and magnetically stirred for 30 minutes to obtain solution B. Slowly add the obtained B solution to A solution, add concentrated hydrochloric acid to adjust the pH to 4, and stir for 30 minutes to obtain stable, uniform, clear and transparent TiO 2 / ZnO sol. Put the sol into a vacuum drying oven and dry it at 80°C to form a xerogel. The xerogel was ground with an agate mortar to obtain a powder. Put the powder into a muffle furnace and heat-treat at 500°C to obtain nano-TiO 2 / ZnO powder. Then the obtained nano-TiO 2 / ZnO powder is hydrophili...

Embodiment 3

[0023] Measure 10ml of tetrabutyl titanate, add 300ml of absolute ethanol to make a solution, drop 3-4 drops of glacial acetic acid at a stirring speed of 150r / min, and magnetically stir for 30min at room temperature to fully mix the solution to obtain A solution. At the same time, another 1 ml of distilled water and 200 ml of absolute ethanol were taken, and ZnO with a molar ratio of tetrabutyl titanate of 6:1 was added for compounding, and magnetically stirred for 30 minutes to obtain solution B. Slowly add the obtained B solution to A solution, add concentrated hydrochloric acid to adjust the pH to 3, and stir for 30 minutes to obtain stable, uniform, clear and transparent TiO 2 / ZnO sol. Put the sol into a vacuum drying oven and dry it at 80°C to form a xerogel. The xerogel was ground with an agate mortar to obtain a powder. Put the powder into a muffle furnace and heat-treat at 600°C to obtain nano-TiO 2 / ZnO powder. Then the obtained nano-TiO 2 / ZnO powder is hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com