Ultra-stable rare earth Y-type molecular sieve and preparation method thereof

一种分子筛、稀土的技术,应用在分子筛催化剂、分子筛和碱交换化合物、化学仪器和方法等方向,能够解决降低分子筛比表面和孔体积、增加稀土离子交换阻力、降低稀土离子利用率等问题,达到提高活性稳定性、减少密度和强度、提高二次利用率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

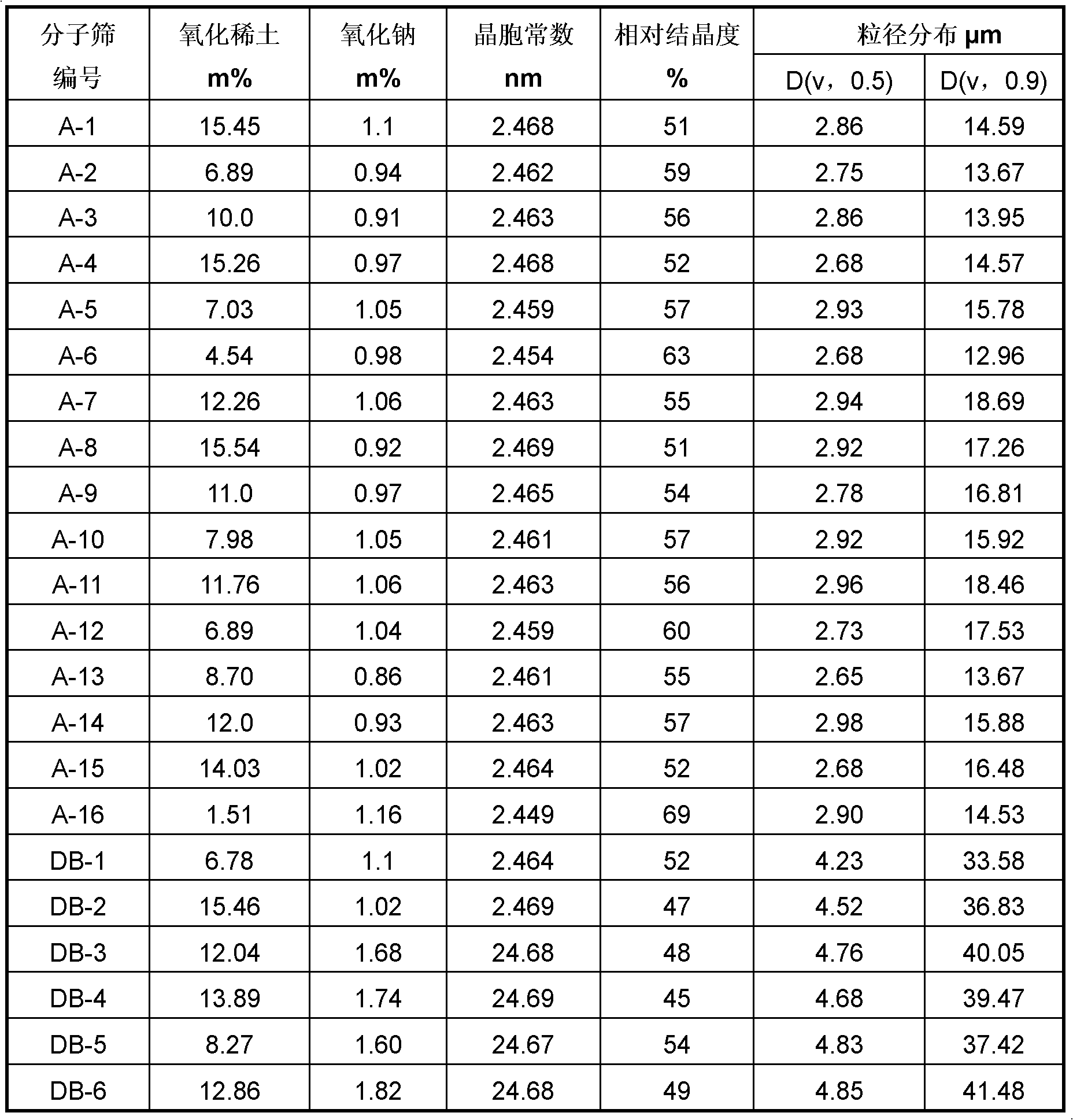

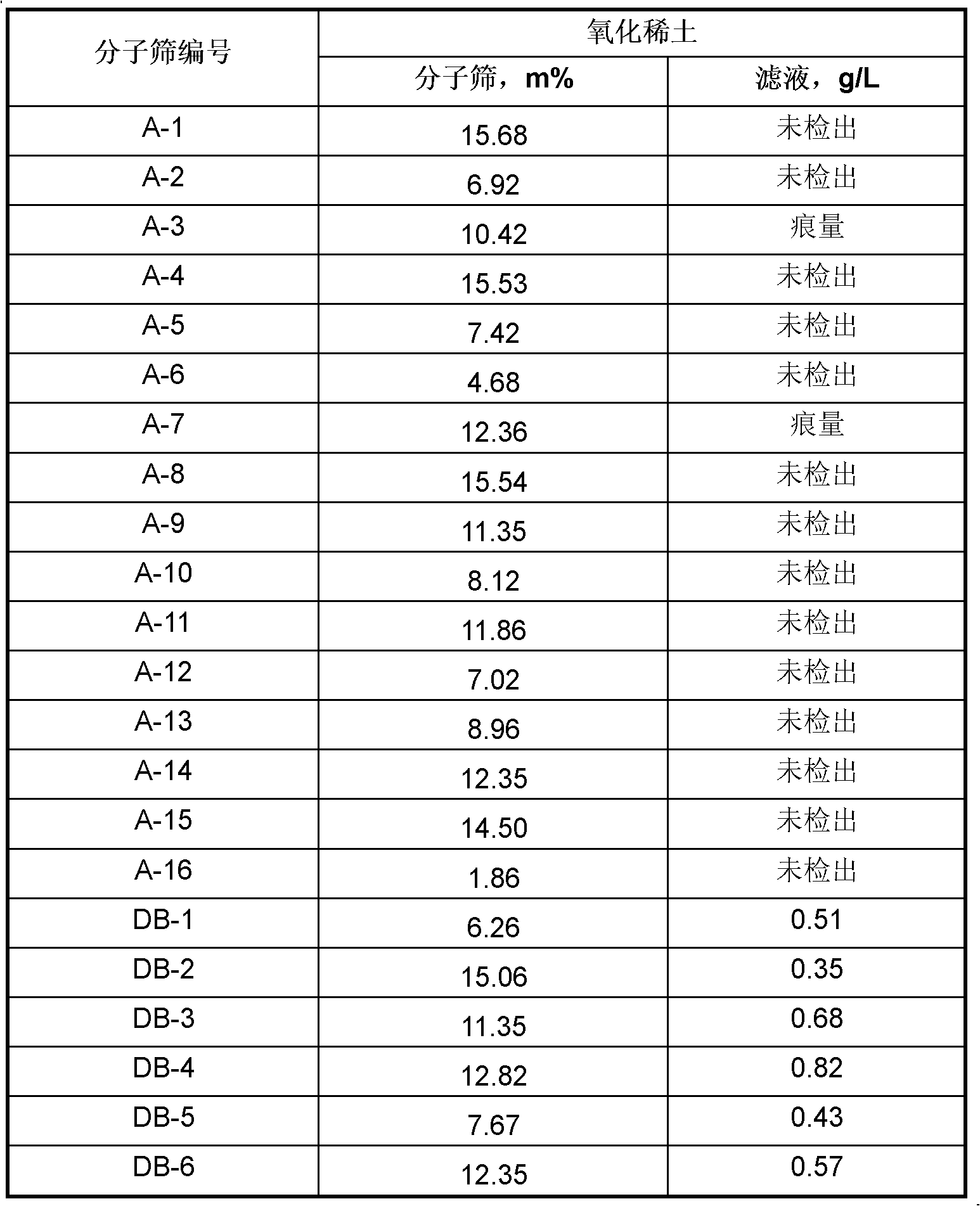

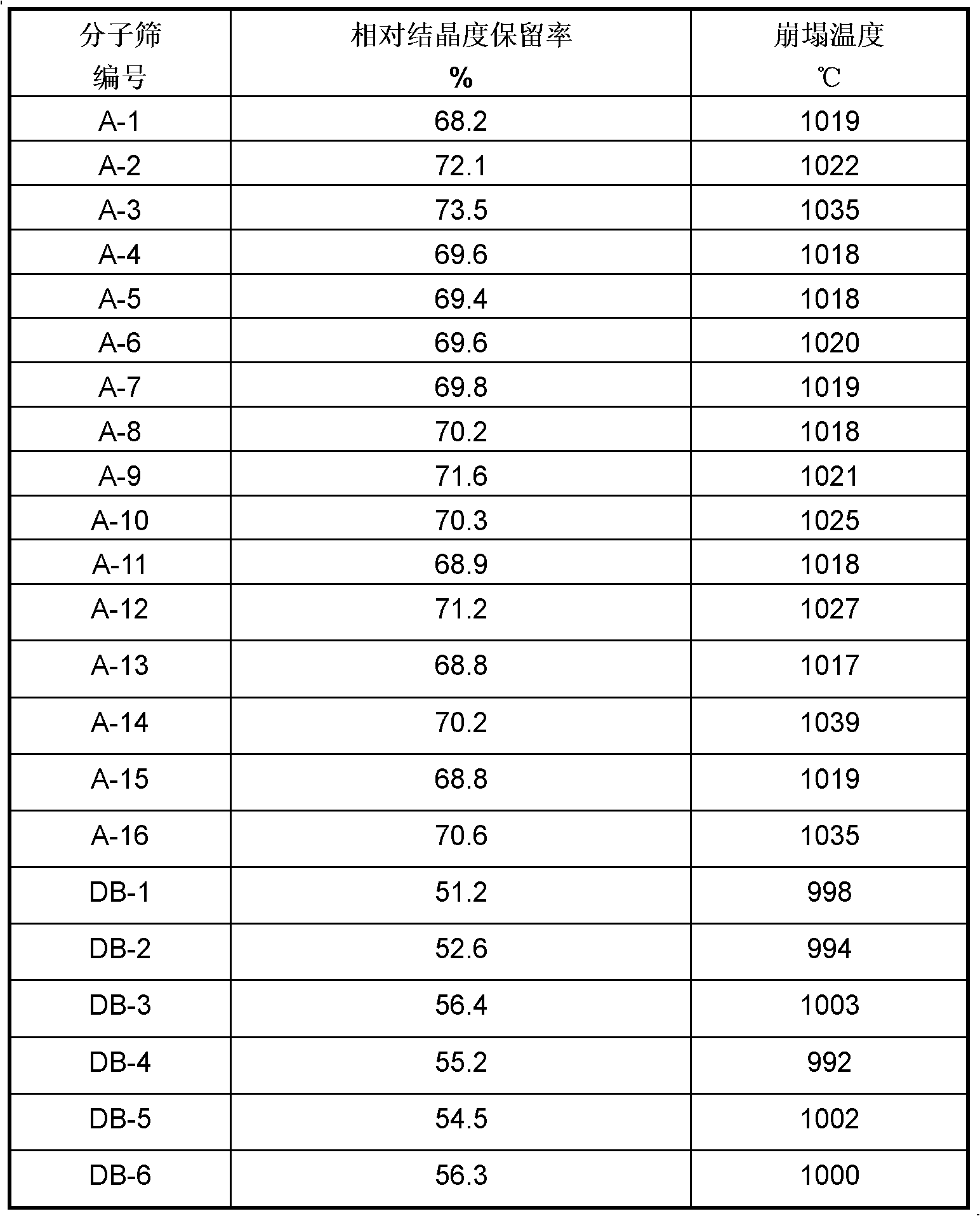

Examples

Embodiment 1

[0044] In the reactor with heating mantle, add 3000gNaY-1 molecular sieve (dry base) and a certain amount of deionized water successively, be allocated to the slurry that solid content is 220g / L, add 82g boric acid and 105 gram scallop powder, then Raise the temperature to 85°C, exchange and react for 0.5 hours under stirring, then filter and wash, put the obtained filter cake in the reaction kettle, and then add 1.67 liters of rare earth chloride to adjust the pH of the system to 4.0, raise the temperature to 80°C, and perform the exchange reaction After 0.3 hours, flash-dry the obtained filter cake to make the water content between 30% and 50%, and finally roast it at 70% water vapor and 670° C. for 1.0 hour to obtain “one-roasted” rare earth sodium Y. In a reaction kettle with a heating jacket, add 500 grams (dry basis) of "cross-baking" ultra-stable rare earth sodium Y molecular sieve and a certain amount of deionized water to make a slurry with a solid content of 120g / L, a...

Embodiment 2

[0046] In the reaction kettle with heating jacket, add 3000gNaY-1 molecular sieve (dry basis) and a certain amount of deionized water successively to prepare a slurry with a solid content of 360g / L, add 0.82 liters of rare earth nitrate, and adjust the system pH= 3.3, heat up to 80°C, exchange reaction for 1.5 hours, then filter and wash, put the obtained filter cake in the reaction kettle, add 202g polyacrylamide and 30g salicylic acid, then heat up to 78°C for dispersion exchange, and stir Under the exchange reaction for 0.5 hours, the resulting filter cake was flash-dried to make the water content 30% to 50%, and finally roasted at 30% water vapor and 630°C for 1.8 hours to obtain the "one-to-one-roasted" rare earth sodium Y. In a reactor with a heating jacket, add 500 grams (dry basis) and deionized water of "cross-baked" ultra-stable rare earth sodium Y molecular sieve to make a slurry with a solid content of 370g / L, add 200g ammonium sulfate, Adjust the pH of the system ...

Embodiment 3

[0051] In a reaction kettle with a heating jacket, add 3000g NaY-1 molecular sieve (dry basis) and deionized water in sequence to prepare a slurry with a solid content of 100g / L, then add 180g citric acid for dispersion pre-exchange, and heat up to 85°C , exchange reaction for 0.5 hours, then add 1.08 liters of rare earth chloride, adjust the pH of the system to 4.5, raise the temperature to 85°C, perform exchange reaction for 1 hour, then filter and wash, and flash-dry the obtained filter cake to make the water content at 30 % to 50%, and finally roasted at 40% water vapor and 540°C for 1.5 hours to obtain "cross-roasting" ultra-stable rare earth sodium Y. In a reactor with a heating jacket, add 500 grams (dry basis) and deionized water of "cross-baking" ultra-stable rare earth sodium Y molecular sieve to make a slurry with a solid content of 145g / L, add 80g of ammonium sulfate, Adjust the pH of the system to 3.5, raise the temperature to 90°C, exchange for 1.2 hours, then fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com