Method for preparing ultra-high rare earth composite oxide ultraviolet screening agent

A rare earth compound and oxide technology, applied in the direction of coating, can solve the problems of DNA damage, skin cancer, dermal fiber damage, and high harm to human body, and achieve the effects of light aggregation, low preparation cost and good dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

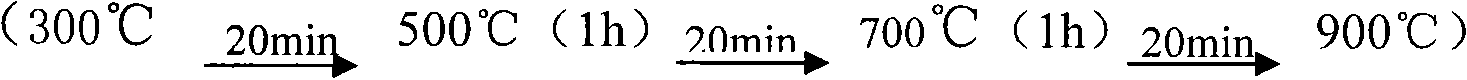

[0017] Example 1: Accurately weigh 7g of yttrium oxide, 2g of zinc oxide, and 1g of titanium oxide and dissolve them in 260ml of deionized water, heat, control the temperature at 60°C, and add 20ml of concentrated nitric acid to dissolve until the solution is clear. At this time, the solution is clear and transparent, and 1g of PEG 6000, then accurately weigh 16g of ammonium bicarbonate, dissolve it in 230ml deionized water with slight heat, add the carbon ammonia solution into the nitric acid mixture, control the temperature at 70°C until the reaction is complete, filter, wash, and put the precursor in the drying box Dry at a constant temperature of 100°C for 12 hours, then place in a muffle furnace and increase the temperature from 300°C to 900°C

[0018]

[0019] , heat preservation 2h, the product is white powder, the white powder particle size D measured by the United States Coulter LS230 laser particle size analyzer 50 It is 75.8nm, after being added into the polyeste...

Embodiment 2

[0020] Example 2: Accurately weigh 6g of yttrium oxide, 3g of zinc oxide, and 1g of titanium oxide, dissolve them in 260ml of deionized water, heat, control the temperature at 60°C, and add 20ml of concentrated nitric acid to dissolve until the solution is clear. At this time, the solution is clear and transparent, and 1g of PEG 6000, then accurately weigh 16g of ammonium bicarbonate, dissolve it in 230ml deionized water with slight heat, add the carbon ammonia solution into the nitric acid mixture, control the temperature at 70°C until the reaction is complete, filter, wash, and put the precursor in the drying box Dry at a constant temperature of 100°C for 12 hours, then place it in a muffle furnace and raise the temperature from 300°C to 900°C (same example 1), and keep it warm for 2 hours. The particle size of the white powder is measured by the American Coulter LS230 laser particle size analyzer 50 It is 80nm, after being added into the polyester resin coating, and detected...

Embodiment 3

[0021] Example 3: Accurately weigh 5g of yttrium oxide, 3g of zinc oxide, and 2g of titanium oxide and dissolve them in 260ml of deionized water, heat, control the temperature at 60°C, and add 20ml of concentrated nitric acid to dissolve until the solution is clear. At this time, the solution is clear and transparent, and 1g of PEG 6000, then accurately weigh 16g of ammonium bicarbonate, dissolve it in 230ml deionized water with slight heat, add the carbon ammonia solution into the nitric acid mixture, control the temperature at 70°C until the reaction is complete, filter, wash, and put the precursor in the drying box Dry at a constant temperature of 100°C for 12 hours, then place it in a muffle furnace and raise the temperature from 300°C to 900°C (same example 1), and keep it warm for 2 hours. The particle size of the white powder is measured by the American Coulter LS230 laser particle size analyzer 50 It is 90nm, after being added into the polyester resin paint, and detecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com