Engraftment type nano-zinc oxide and production process thereof

A nano-zinc oxide and production process technology, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of easy reunion of products and insufficient preparation methods, so as to improve purity and quality and expand market adaptability , Eliminate the effect of polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

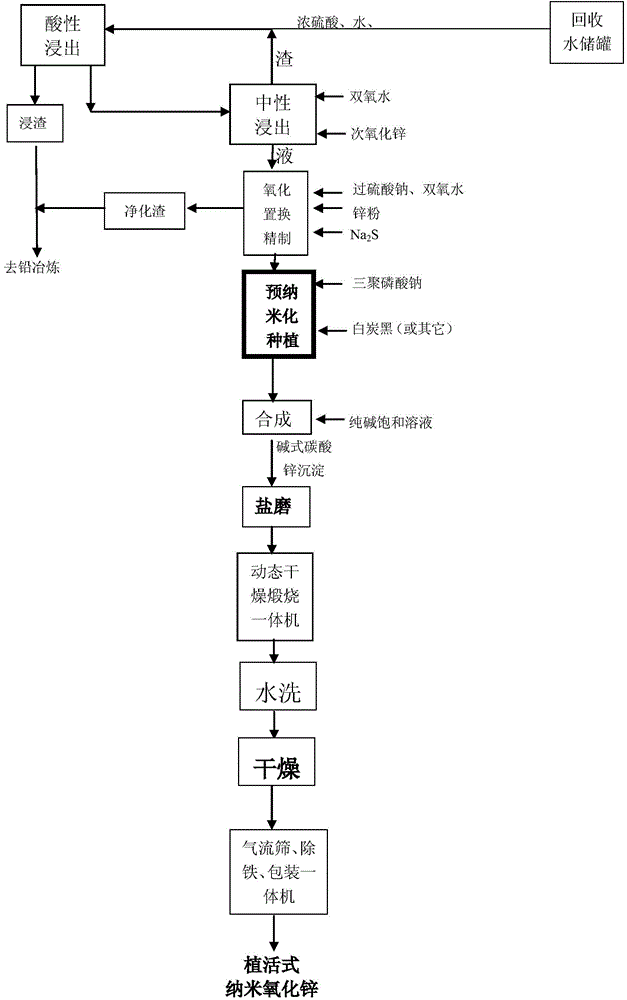

[0073] Such as figure 1 Shown, a kind of planting type nano-zinc oxide and production technology thereof, comprises the following steps:

[0074] (1) Leaching: With sulfuric acid as the leaching solvent, the zinc in the secondary zinc oxide is leached to make zinc sulfate solution; the main reaction formula of this step is as follows:

[0075] ZnO+H 2 SO 4 =ZnSO 4 +H 2 o

[0076] The leaching step is divided into two stages of neutral leaching and acid leaching, which are carried out in two leaching tanks respectively. The filter residue after neutral leaching is added into the acid leaching tank under stirring and then leached, and the acid leaching filter residue is discarded. The acidic leaching solution is added to the neutral leaching tank again as a leaching solvent, and the secondary zinc oxide is put into the neutral leaching tank under stirring, and the leached leaching solution enters the next step, and the cycle repeats like this;

[0077] During the neutral l...

Embodiment 2

[0096] The plant active nano-zinc oxide and its production process of the present embodiment comprise the following steps:

[0097] (1) Leaching: With sulfuric acid as the leaching solvent, the zinc in the secondary zinc oxide is leached to make zinc sulfate solution; the main reaction formula of this step is as follows:

[0098] ZnO+H 2 SO 4 =ZnSO 4 +H 2 o

[0099] The leaching step is divided into two stages of neutral leaching and acid leaching, which are carried out in two leaching tanks respectively. The filter residue after neutral leaching is added into the acid leaching tank under stirring and then leached, and the acid leaching filter residue is discarded. The acidic leaching solution is added to the neutral leaching tank again as a leaching solvent, and the secondary zinc oxide is put into the neutral leaching tank under stirring, and the leached leaching solution enters the next step, and the cycle repeats like this;

[0100] During the neutral leaching, second...

Embodiment 3

[0119] The plant active nano-zinc oxide and its production process of the present embodiment comprise the following steps:

[0120] (1) Leaching: With sulfuric acid as the leaching solvent, the zinc in the secondary zinc oxide is leached to make zinc sulfate solution; the main reaction formula of this step is as follows:

[0121] ZnO+H 2 SO 4 =ZnSO 4 +H 2 o

[0122] The leaching step is divided into two stages of neutral leaching and acid leaching, which are carried out in two leaching tanks respectively. The filter residue after neutral leaching is added into the acid leaching tank under stirring and then leached, and the acid leaching filter residue is discarded. The acidic leaching solution is added to the neutral leaching tank again as a leaching solvent, and the secondary zinc oxide is put into the neutral leaching tank under stirring, and the leached leaching solution enters the next step, and the cycle repeats like this;

[0123] During the neutral leaching, zinc o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com