Magnetic nanoparticle, preparation method and application of magnetic nanoparticle

A magnetic nanoparticle and nanomagnetism technology, applied in the field of nanomaterial medicine, can solve problems such as high Curie temperature, damage to tissue cells, complicated process, etc., and achieve the effects of low Curie temperature, light degree of agglomeration, and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Dissolve 2g of polyvinyl alcohol (molecular weight: 1700) in 70ml of deionized water, soak for 20 hours, then stir and heat to 90°C to completely dissolve the polyvinyl alcohol, and then maintain the temperature at 70°C;

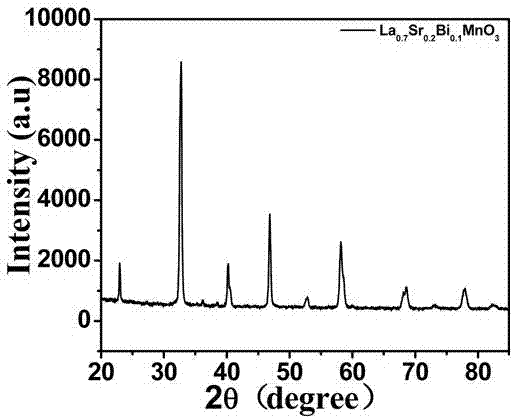

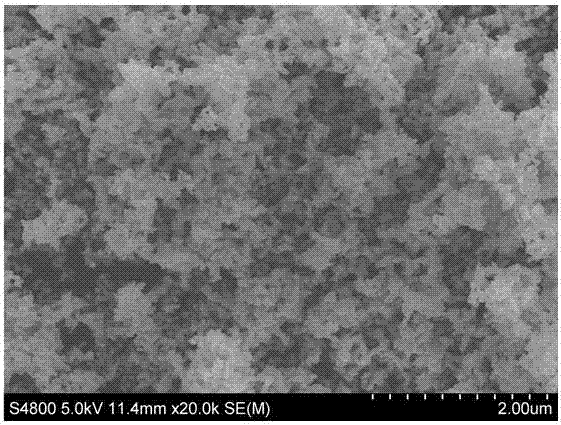

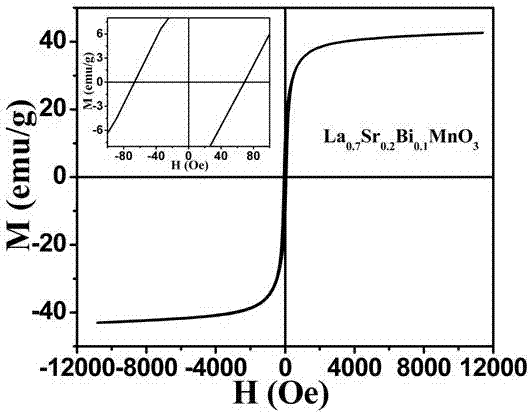

[0033] 2) La (NO 3 ) 3 ·6H 2 O (3.01 mmol, 1.303 g), Sr(NO 3 ) 2 (0.86 mmol, 0.181 g), 50% manganese nitrate solution (4.3 mmol, 1 ml) in 30 ml deionized water, Bi 2 o 3 (0.215 mmol, 0.1 g) was dissolved in 1ml of concentrated nitric acid, then mixed evenly and added to the aqueous solution of polyvinyl alcohol dissolved, the mixed solution was made uniform by magnetic stirring, the pH was adjusted to 7 by adding ammonia water, and the temperature was maintained at 70°C until the water slowed down. Slow evaporation forms a viscous liquid. Put the viscous liquid above into an oven for drying at 80°C, put the dried dry gel into a resistance furnace to raise the temperature to 800°C at a heating rate of 5°C / min, keep it at 800°C for 5 hours, and...

Embodiment 2

[0045] 1) Dissolve 2g of polyvinyl alcohol (molecular weight: 1750) in 70ml of deionized water, soak for 15 hours, then stir and heat to 100°C to completely dissolve the polyvinyl alcohol, and then maintain the temperature at 70°C;

[0046] 2) La (NO 3 )3 ·6H 2 O (3.01 mmol, 1.303 g), Sr(NO 3 ) 2 (0.86 mmol, 0.181 g), 50% manganese nitrate solution (4.3 mmol, 1 ml) in 30 ml deionized water, Bi 2 o 3 (0.215 mmol, 0.1 g) was dissolved in 1ml of concentrated nitric acid, then mixed evenly and added to the aqueous solution of polyvinyl alcohol dissolved, the mixed solution was made uniform by magnetic stirring, and ammonia water was added to adjust the pH to 7.5, and then the temperature was maintained at 80°C until the water slowed down. Slow evaporation forms a viscous liquid. Put the viscous liquid above into an oven for drying at 80°C, put the dried dry gel into a resistance furnace to raise the temperature to 800°C at a heating rate of 5°C / min, keep it at 800°C for 8 hou...

Embodiment 3

[0049] 1) Dissolve 2g of polyvinyl alcohol (molecular weight: 1800) in 70ml of deionized water, soak for 24 hours, then stir and heat to 90°C to completely dissolve the polyvinyl alcohol, and then maintain the temperature at 80°C;

[0050] 2) La (NO 3 ) 3 ·6H 2 O (3.01 mmol, 1.303 g), Sr(NO 3 ) 2 (0.86 mmol, 0.181 g), 50% manganese nitrate solution (4.3 mmol, 1 ml) in 30 ml deionized water, Bi 2 o 3 (0.215 mmol, 0.1 g) was dissolved in 1ml of concentrated nitric acid, and then mixed evenly and added to the aqueous solution of polyvinyl alcohol dissolved, and the mixed solution was made uniform by magnetic stirring, and the pH was adjusted to 8 by adding ammonia water, and the temperature was maintained at 70°C until the water was slow Slow evaporation forms a viscous liquid. Put the viscous liquid above into an oven for drying at 70°C, put the dried dry gel into a resistance furnace and raise the temperature to 850°C at a heating rate of 8°C / min, keep it at 850°C for 5 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com