Preparation method of cellular V-Ti low-temperature smoke denitration catalyst

A denitrification catalyst and low-temperature flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as unfavorable long-term operation of the denitrification system, difficulty in ensuring catalyst life, and large bed resistance, etc., to achieve Guaranteed service life, good mechanical properties and low smoke resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

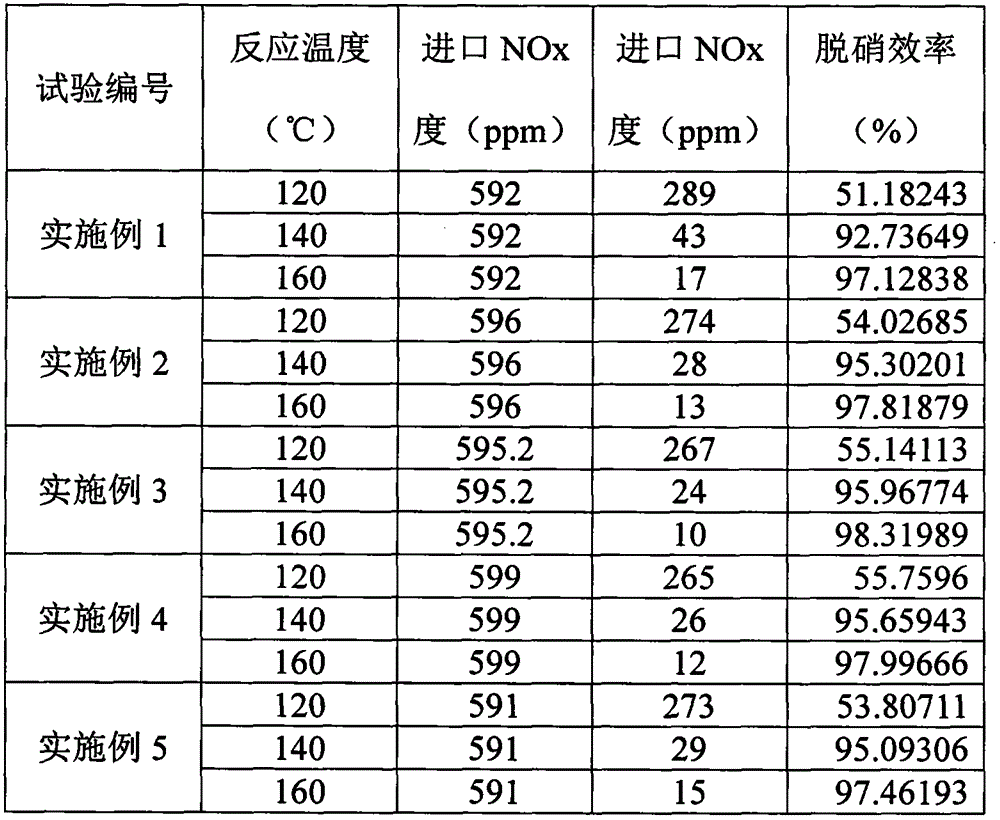

Embodiment 1

[0029] (1) Mixing process

[0030] In the reactor, add a certain amount of deionized water and heat to 80 ° C, TiO 2 , providing V 2 o 5 The salt, salt and oxalic acid that provide oxide additives are added to the reactor according to the mass of 280kg: 17kg: 20kg: 40kg, and react for 1h. After the material in the reactor is muddy, dry at 160°C for 50-60min, transfer to the calciner Calcined in the kiln at 250-450°C for 50-60min and pulverized into granular catalyst.

[0031] (2) Forming process

[0032] Take by weighing the granular catalyst 200kg that mixing process gained, add stearic acid 8kg, add carboxymethacrylic acid 6.4kg, add glass fiber 11kg, add pure ammoniacal liquor 6kg, add deionized water 80kg through mud refining, vacuum mud refining, in Aged for 24 hours under constant temperature and humidity conditions, molded, dried at 60°C for 60-90 hours, and sintered in a tunnel kiln at 180-450°C for 2 hours to become a honeycomb denitrification catalyst.

Embodiment 2

[0034] (1) Mixing process

[0035] In the reactor, add a certain amount of deionized water and heat to 80 ° C, TiO 2 , providing V 2 o 5 The salt, the salt and oxalic acid that provide the oxide auxiliary agent are added in the reactor according to the mass of 280kg: 30.2kg: 20kg: 40kg, and react for 1h. Calcined at 250-450°C for 50-60 minutes in a calcining kiln and pulverized into a granular catalyst.

[0036] (2) forming process (same as the forming process of embodiment 1)

Embodiment 3

[0038] (1) Mixing process

[0039] In the reactor, add a certain amount of deionized water and heat to 80 ° C, TiO 2 , providing V 2 o 5 The salt, salt and oxalic acid that provide oxide additives are added to the reactor according to the mass of 280kg: 26kg: 20kg: 40kg, and react for 1h. The material in the reactor is in the form of mud, dried at 160°C for 50-60min, and transferred to the calciner. Calcined in the kiln at 250-450°C for 50-60min and pulverized into granular catalyst.

[0040] (2) forming process (same as the forming process of embodiment 1)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com