Preparation method and application of ceramic preform

A prefabricated body and ceramic technology, which is applied in the field of preparation of ceramic prefabricated bodies, can solve problems such as being unable to apply to industrial production, unable to meet the needs of wear-resistant parts, and restricting long-term development, so as to improve wetting ability, increase thickness, and improve the use of workpieces. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the ceramic preform described in this embodiment is as follows:

[0032] (1) According to the mass ratio of water glass and 20 mesh zirconium corundum ceramic particles of 1:20, the water glass and the ceramic particles are uniformly mixed to make the water glass evenly adhere to the surface of the ceramic particles to obtain ceramic particles coated with water glass. ;

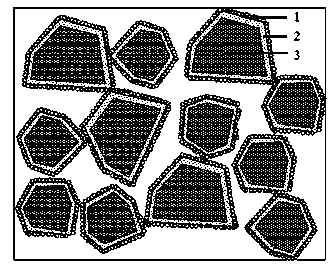

[0033] (2) Mix the titanium carbide powder and alumina powder thoroughly, and then add them to the ceramic particles coated with water glass obtained in step (1), so that the titanium carbide powder and alumina powder are uniformly coated on the surface of the ceramic particles , Make the surface of ceramic particles form a coating layer with good wettability with molten metal, such as figure 1 As shown, the addition amount of titanium carbide is 3% of the mass of ceramic particles, the powder size is 0.5um, the addition amount of alumina is 0.5% of the mass of ceramic particles, a...

Embodiment 2

[0038] The preparation method of the ceramic preform described in this embodiment is as follows:

[0039] (1) The silica sol and PVA are mixed in a ratio of 20:1 and then mixed with 16 mesh black corundum ceramic particles in a mass ratio of 1:24 to make the binder evenly adhere to the surface of the ceramic particles to obtain a bonded Agent-coated ceramic particles;

[0040] (2) Mix the boron carbide powder and zirconia powder thoroughly, and then add them to the ceramic particles coated with silica sol obtained in step (1), so that the boron carbide powder and zirconia powder are evenly coated on the surface of the ceramic particles , Make the surface of ceramic particles form a coating layer with good wettability with molten metal, wherein the addition of titanium carbide is 9% of the mass of ceramic particles, the powder size is 3um, and the addition of alumina is 1.2% of the mass of ceramic particles. The powder size is 25um;

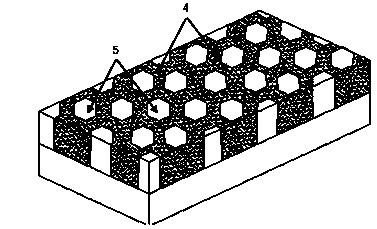

[0041] (3) Fill the mixed materials in step (2) ...

Embodiment 3

[0045] The preparation method of the ceramic preform described in this embodiment is as follows:

[0046] (1) According to the mass ratio of polyaluminum chloride and 8 mesh silicon carbide ceramic particles of 1:28, the polyaluminum chloride and the ceramic particles are uniformly mixed to make the polyaluminum chloride uniformly adhere to the surface of the ceramic particles to obtain the polymerized Ceramic particles coated with aluminum chloride;

[0047] (2) Fully mix the silicon carbide powder and calcium oxide powder, and then add them to the polyaluminum chloride coated ceramic particles obtained in step (1), so that the silicon carbide powder and calcium oxide powder are evenly coated on the ceramic The surface of the particles makes the surface of the ceramic particles form a coating layer with good wettability with the molten metal. The addition of titanium carbide is 18% of the mass of the ceramic particles, the powder size is 12um, and the addition of alumina is 2.5 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com