Catalyst preparation method for efficiently catalyzing organic pollutant in ozone oxidation water

A technology of ozone oxidation and catalyst, which is applied in the research of catalytic ozonation of organic pollutants in water, and the preparation of mesoporous zirconia-supported nano-manganese oxide catalyst, which can solve the problems of poor effect and serious metal dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical characteristics and advantages of the present invention can be seen through the embodiments and application examples given below.

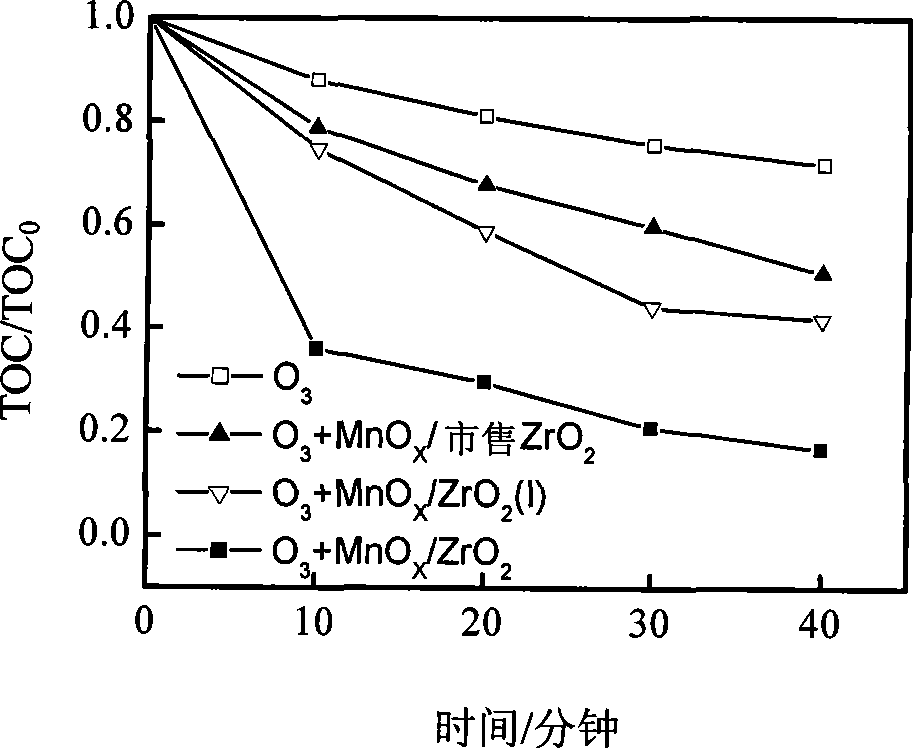

[0012] 1. MnO X / ZrO 2 Structural Properties of Catalysts

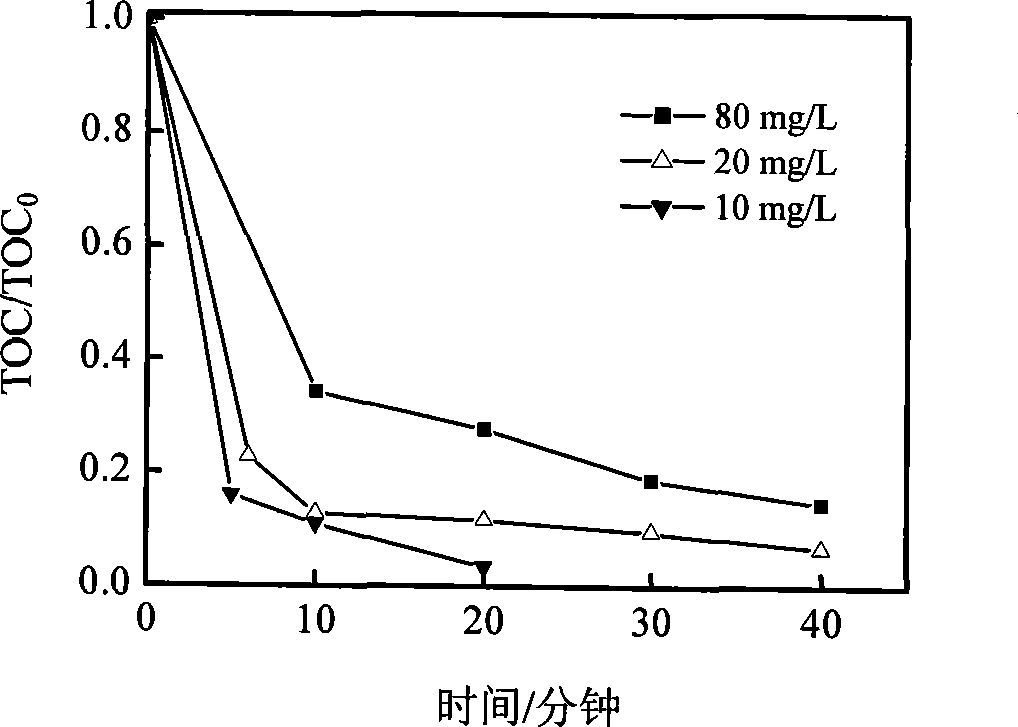

[0013] The preparation of the catalyst adopts the equal-volume impregnation method. A certain amount of manganese acetate is added to deionized water, and then a certain amount of mesoporous zirconia is added to the solution to make MnO X / ZrO 2 Medium Mn (as MnO 2 Calculation) percentage is 1-15wt%, impregnated at room temperature for 0.5-6 hours, the obtained system is dried in an oven at 100-140°C for 1-6 hours, then washed with deionized water, and then dried at 100-140°C for 1 hour -6 hours, and finally calcined the obtained powder at 300-500°C for 2-6 hours to obtain MnO X / ZrO 2 sample. In order to compare the superiority of the catalyst prepared by the present invention, the same preparation method was adopted with mesoporous zirconia and commercially a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com