Anti-cracking and anti-aging blend material for oil pipe of automobile

A technology for oil pipes and automobiles, which is applied in the field of anti-cracking and aging blending materials for automobile oil pipes. It can solve the problems of poor fusion of plastic boxes and rubber, and product quality can not keep up. It achieves low price, good aging resistance, and extrusion process. Good performance in sex and vulcanization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

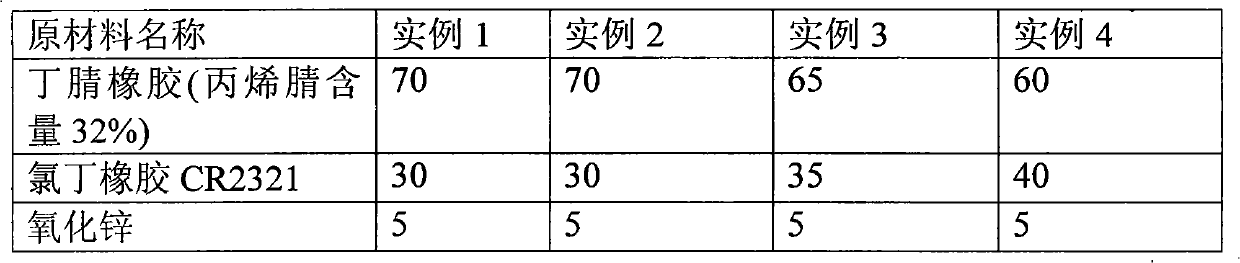

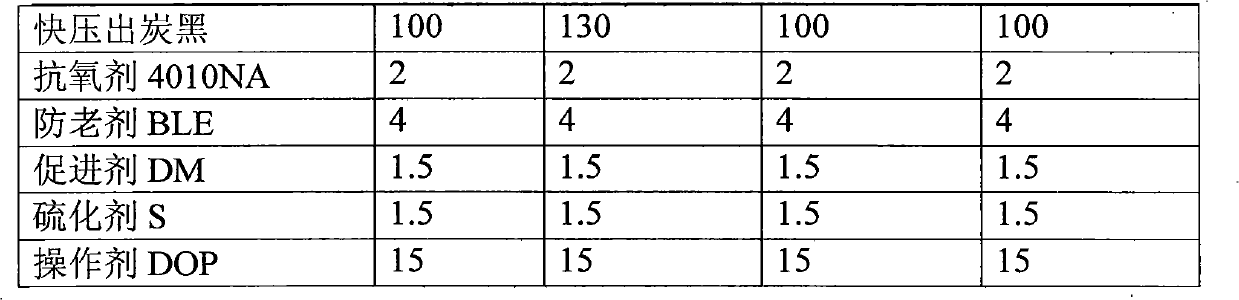

[0021] Table 1 Raw material ratio (parts by weight)

[0022]

[0023]

[0024] The preparation method is as follows:

[0025] The first step: Weigh the raw materials according to the above weight percentage

[0026] Step 2: Use a rubber internal mixer to mix the rubber, active agent, anti-aging agent, and filler evenly between 80°C and 120°C.

[0027] Step 3: Use the second-stage rubber mixing to add the vulcanization accelerator on the open mill between 40°C and 60°C and mix evenly.

[0028] Step 4: Extrude at 70°C.

[0029] Step 5: vulcanization molding under the condition of 150°C×30 minutes.

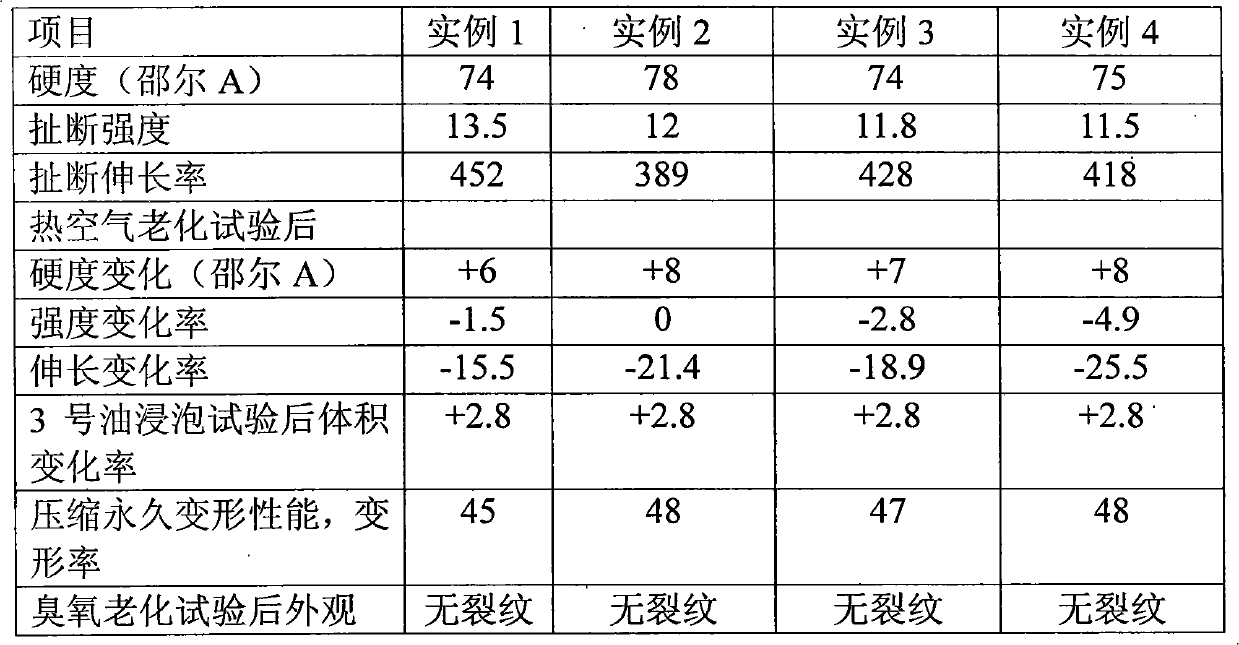

[0030] Table 2 The nitrile rubber / chloroprene rubber blend material prepared by the above method, the main properties are as follows.

[0031]

[0032] The above experimental data proves that the present invention has certain quality stability, is suitable for processing oil-resistant oil pipes, and is also suitable for processing and manufacturing sealing strips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com