A kind of preparation method of damping rubber

A technology of shock-absorbing rubber and preparation steps is applied in the field of preparing shock-absorbing rubber, which can solve the problems of short service life, inability to be dissipated in time, and accelerated thermal-oxidative aging of rubber, so as to improve roughness and avoid thermal-oxidative aging of rubber. , to avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

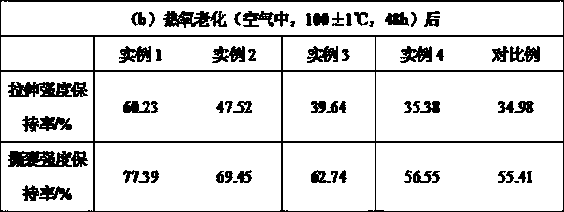

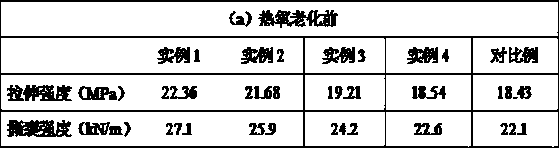

Examples

example 1

[0020] According to the mass ratio of 1:60, mix the alkali-free glass fiber and the dopamine solution with a mass concentration of 2g / L and pour it into a beaker, and move the beaker into a magnetic stirrer with a digital constant temperature and speed measurement at a temperature of 60°C and a speed of 400r / min. Stir and mix at constant temperature for 60 minutes, filter to obtain a filter cake, which is the pretreated glass fiber; add the obtained pretreated glass fiber and 10% ferric chloride solution in a mass ratio of 1:40 into the reactor, and The temperature is 50°C, the rotation speed is 400r / min, after stirring and dispersing at constant temperature for 60min, add 10% urea solution with a mass fraction twice the volume of ferric chloride solution to the reaction kettle dropwise, and control the dropping rate of urea solution to 10mL / min, when the urea solution is added dropwise, continue to stir the reaction at constant temperature for 3h, and when the reaction is ove...

example 2

[0022]In parts by weight, successively take 100 parts of hydrogenated nitrile rubber, 10 parts of polymethyl methacrylate, 10 parts of polyvinyl chloride resin, 10 parts of C5 petroleum resin, 10 parts of glass fiber, 3 parts of sulfur, and 3 parts of accelerator M, 3 parts of anti-aging agent, 2 parts of plasticizer, first put the hydrogenated nitrile rubber in an open mill, and masticate for 10 minutes at a temperature of 40 ° C, then add polymethyl methacrylate, polychloride Vinyl resin, C5 petroleum resin, glass fiber, sulfur, accelerator M, anti-aging agent and plasticizer were mixed for 10 minutes at a temperature of 150°C. During the mixing process, a strength of 50T was applied to the materials in the open mill. After the mixing is completed, discharge the material, and then let it stand at room temperature for 8 hours to obtain the mixed rubber, and transfer the obtained mixed rubber into a flat vulcanizing machine at a temperature of 200 °C and a pressure of 30 MPa. ...

example 3

[0024] According to the mass ratio of 1:60, mix glass fiber and dopamine solution with a mass concentration of 2g / L and pour it into a beaker, and move the beaker into a magnetic stirrer with a digital display, constant temperature and speed measurement, at a temperature of 60°C and a speed of 400r / min. , stirred and mixed at a constant temperature for 60 minutes, filtered to obtain a filter cake, which is the pretreated glass fiber; the obtained pretreated glass fiber and a mass fraction of 10% ferric chloride solution were added to the reactor at a mass ratio of 1:40, and the temperature was At 50°C and a rotating speed of 400r / min, stir and disperse at a constant temperature for 60min, then add a 10% urea solution with a mass fraction twice the volume of the ferric chloride solution to the reactor dropwise, and control the dropping rate of the urea solution to 10mL / min , after the addition of the urea solution is completed, continue to stir and react at a constant temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com