Dyeing wastewater advanced treatment method and device by using ozone, oxydol and activated carbon

A printing and dyeing wastewater and advanced treatment technology, applied in the direction of oxidation water/sewage treatment, water/sewage treatment, textile industry wastewater treatment, etc., can solve the problems of high cost and low utilization rate, and achieve low operating cost and high ozone utilization rate , the treatment effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

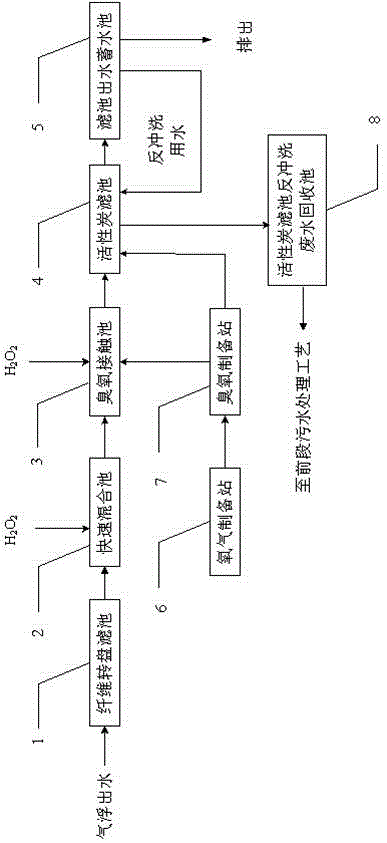

[0027] Please refer to the attached figure 1 As shown, the present invention is a device for advanced treatment of printing and dyeing wastewater by ozone, hydrogen peroxide and activated carbon, which consists of a fiber turntable filter 1, a rapid mixing tank 2, an ozone contact tank 3, an activated carbon filter 4, and a filter effluent reservoir 5. Oxygen preparation station 6, ozone preparation station 7 and active carbon filter backwash wastewater recovery pool 8 are composed of several parts.

[0028] Wherein, the fiber rotary disc filter 1, the rapid mixing tank 2, the ozone contact tank 3, the activated carbon filter 4 and the filter outlet water storage tank 5 are connected in sequence.

[0029] The oxygen preparation station 6 is connected to the ozone preparation station 7; the ozone preparation station 7 is connected to the ozone contact tank 3 and the activated carbon filter tank 4 respectively.

[0030] A backwash pipe is connected between the activated carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com