Method and system for ozone removal and gas purification of cabin of aircraft

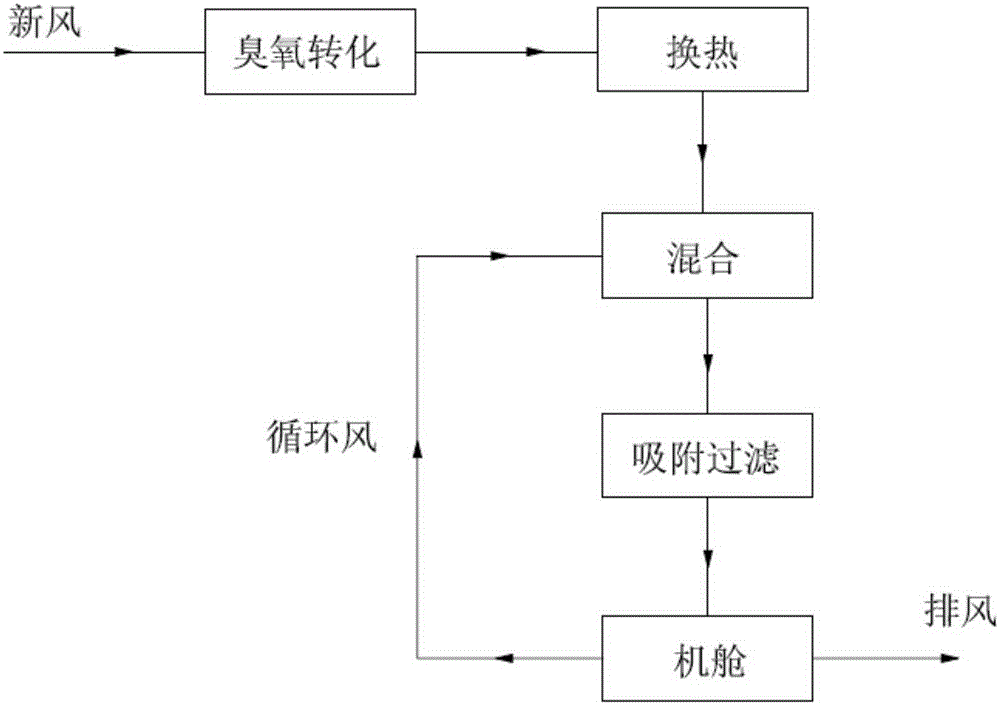

A gas purification system and technology in the cabin, which is applied in the field of gas purification and ozone removal in the aircraft cabin, can solve the problems of complex and bulky systems and low removal efficiency, and achieve large gas flow, compact structure, high efficiency and economy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

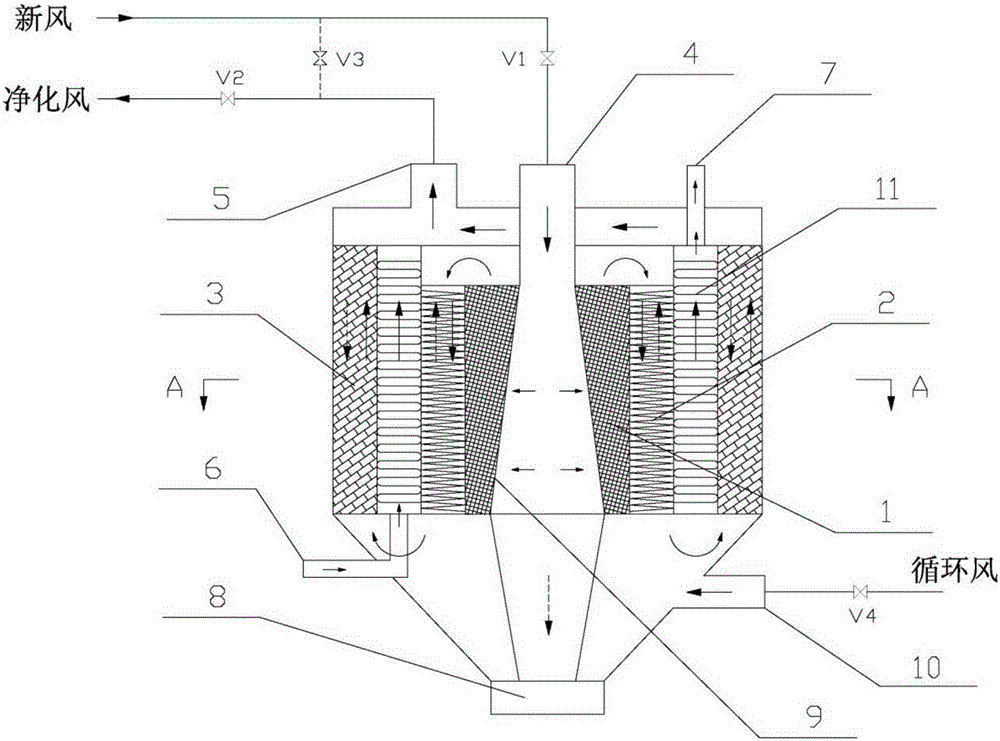

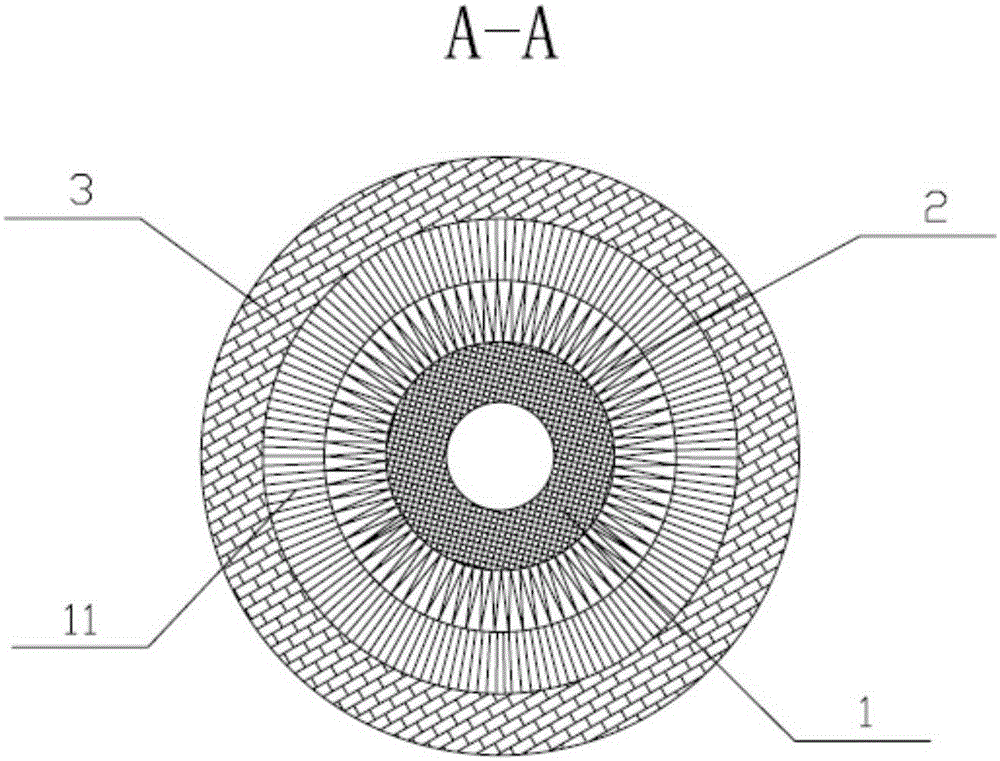

[0049] Combine below figure 2 , image 3 The present invention is described in detail, the following are only preferred embodiments of the present invention, but the scope of the present invention cannot be limited with this, especially the shape of the system, and all equivalent changes and modifications done according to the application scope of the present invention shall belong to scope covered by the present invention.

[0050] The fresh air introduced from the outside of the aircraft cabin enters the gas purification system through the air inlet 4. At this time, the valves V1, V2, and V4 are opened, and the back purge valve V3 is closed. The center tube is perforated, and the inside of the center tube is fixed with a wire mesh filter 9. The material of the wire mesh filter is stainless steel, and the mesh aperture is 200-400 orders. Fresh air filters through the wire mesh filter 9 to remove particulate matter therein. The filtered fresh air enters the ozone removal ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com