Method for treating dyeing wastewater in transfer piping by ozone

A technology for printing and dyeing wastewater and transportation pipelines, applied in the application field, can solve the problems of low mass transfer efficiency, achieve high mass transfer efficiency, short treatment process, and high effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

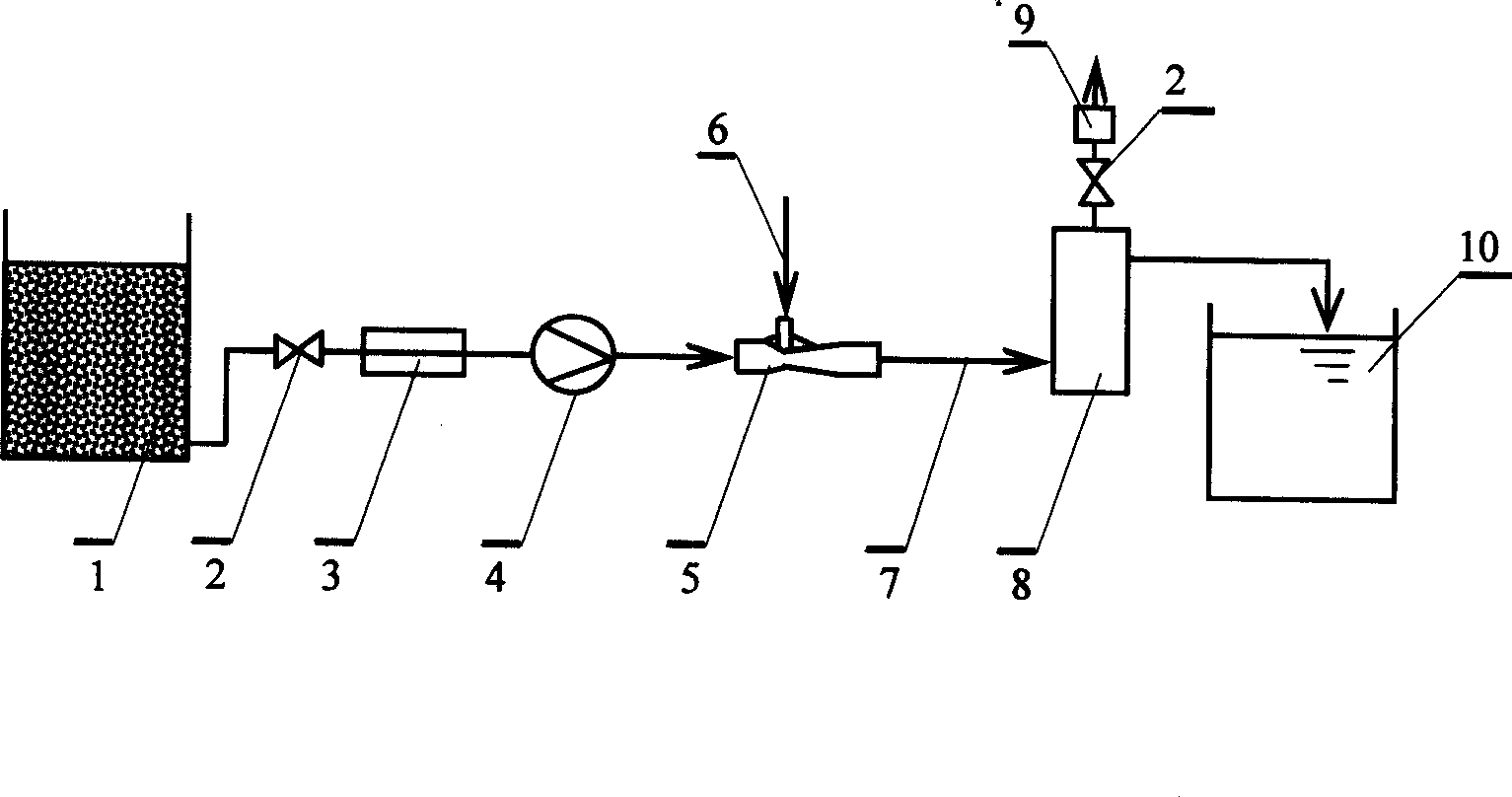

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

[0011] The printing and dyeing wastewater 1 after pretreatment such as sand filtration, enters the ejector 5 after passing through the control valve 2, the flow meter 3 and the pump 4, and contacts with the ozone 6 in the ejector 5, and the mass transfer efficiency of the ozone is greater than 98%; then printing and dyeing Wastewater and ozone complete the oxidation reaction in the pipeline 7, the reaction time is 1s~5s, and the length of the pipeline 7 is 3~10m; the ozonated printing and dyeing wastewater enters the gas-liquid separation device 8 to separate the remaining ozone, and then the ozone After entering the residual ozone elimination device through the control valve 2, it becomes oxygen and then discharged; the decolorization rate of the effluent 10 can reach more than 98%, and the COD removal rate can reach more t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com