Sludge ozone oxidation and reduction device and use method thereof

A technology for ozone oxidation and sludge, which is applied in chemical instruments and methods, oxidation treatment of sludge, water/sludge/sewage treatment, etc., can solve the problems of insufficient utilization of resources, insufficient reaction of ozone and sludge, and ozone Low utilization rate and other problems, to achieve the effect of maximizing the utilization of resources, reducing the amount of ozone dosage, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

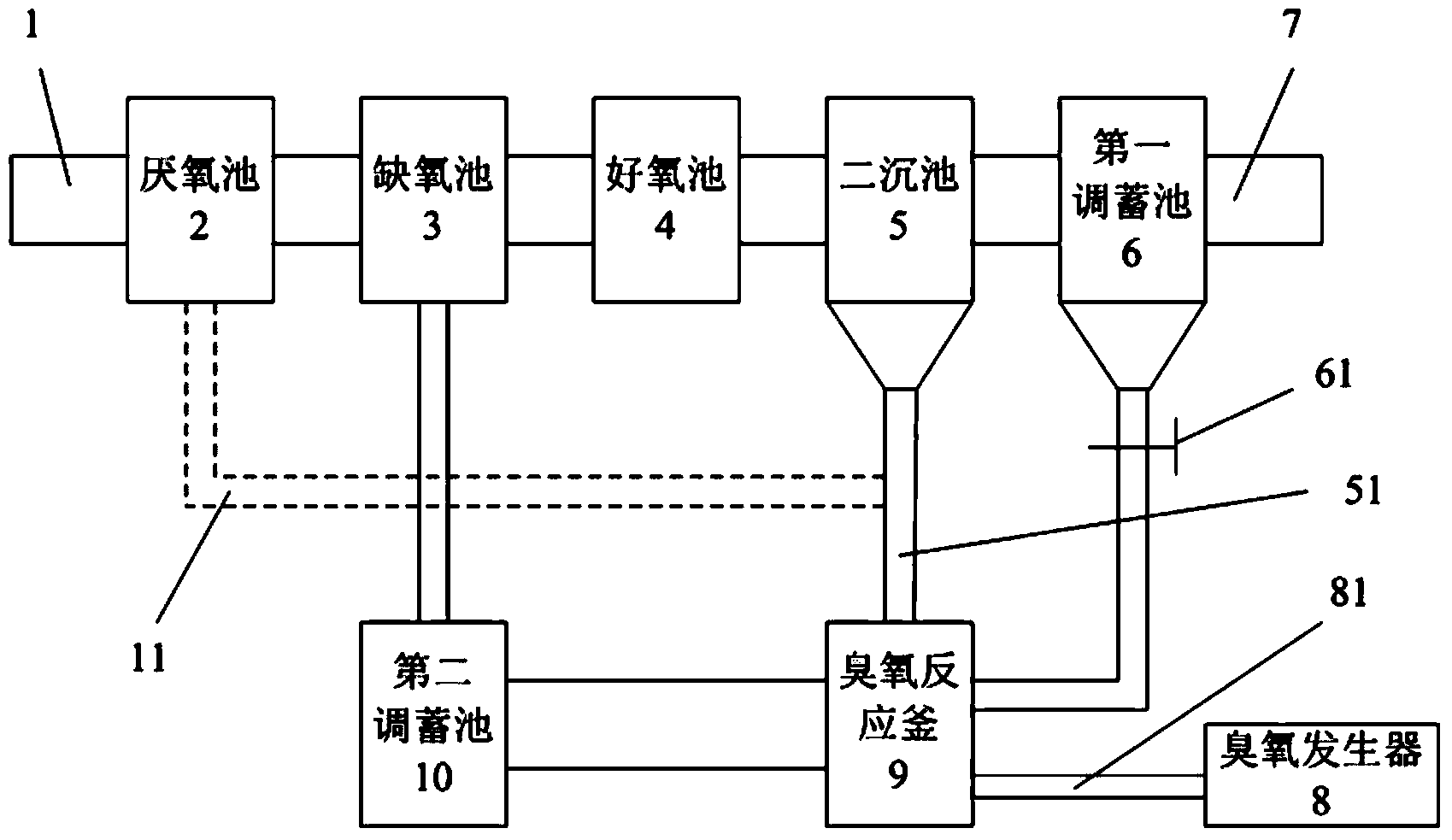

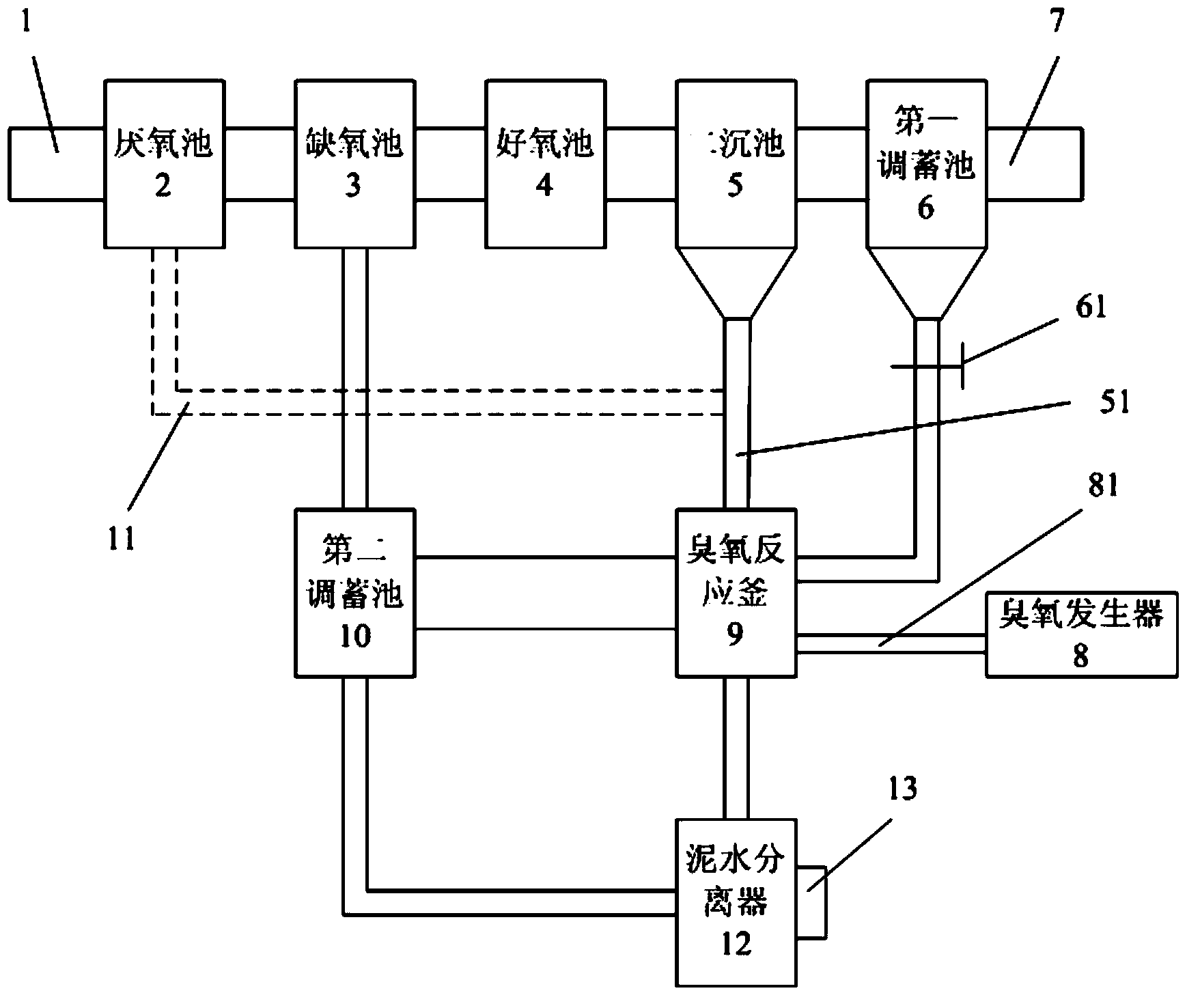

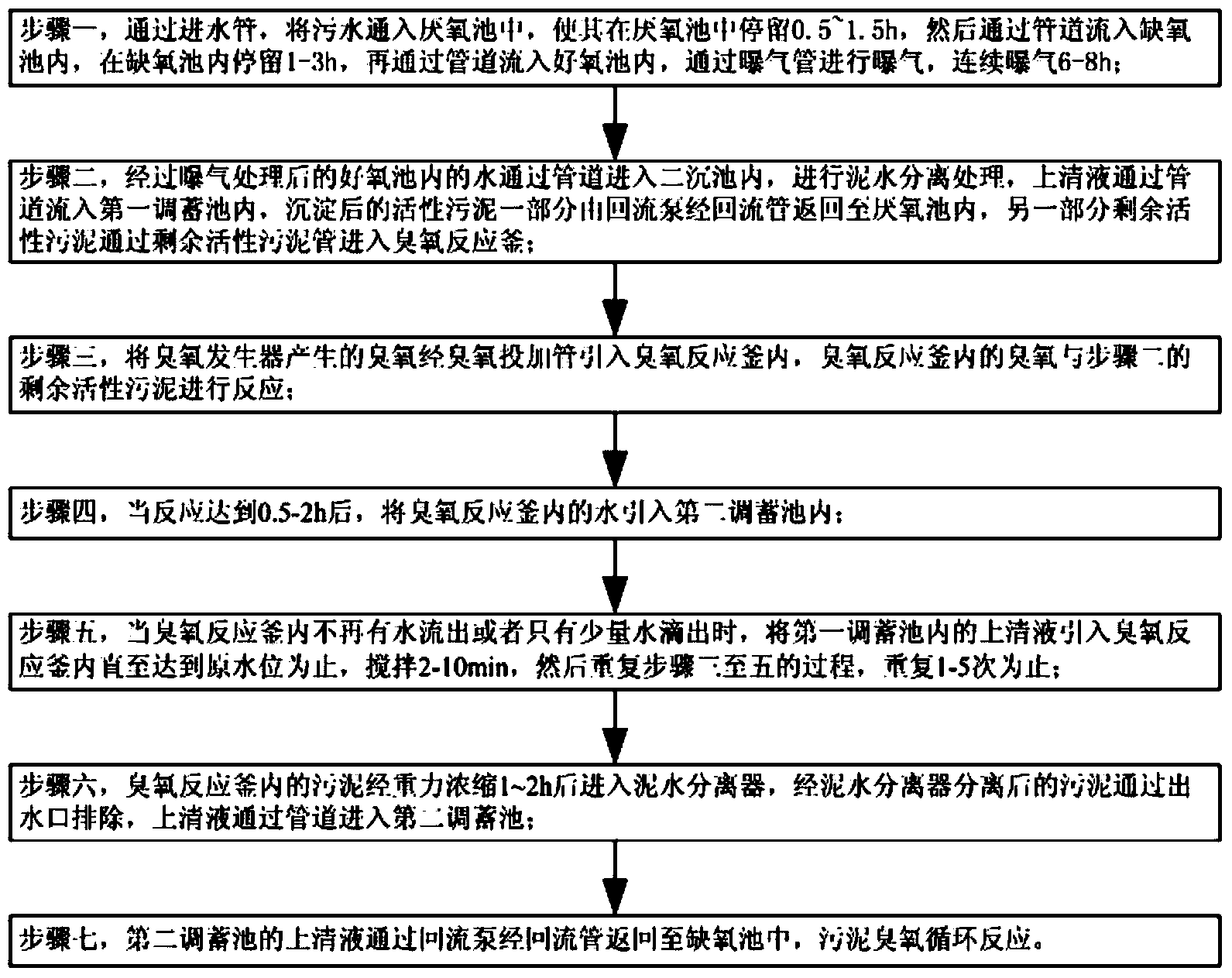

[0048] Pass the sewage into the anaerobic tank through the water inlet pipe, make it stay in the anaerobic tank for 1 hour, then flow into the anoxic tank through the pipeline, stay in the anoxic tank for 2 hours, then flow into the aerobic tank through the pipeline, and pass through the aeration tube Aeration is performed continuously for 8 hours; after the aeration treatment, the water in the aerobic tank enters the secondary sedimentation tank through the pipeline for mud-water separation treatment, and the supernatant flows into the first storage tank through the pipeline, and the activated sludge after sedimentation One part is returned to the anaerobic tank by the return pump through the return pipe, and the other part of the remaining activated sludge enters the ozone reactor through the remaining activated sludge pipe; the ozone generated by the ozone generator is introduced into the ozone reactor through the ozone dosing pipe, specifically Introduce 0.01g / g MLSS each t...

Embodiment 2

[0050] Pass the sewage into the anaerobic tank through the water inlet pipe, make it stay in the anaerobic tank for 1 hour, then flow into the anoxic tank through the pipeline, stay in the anoxic tank for 2 hours, then flow into the aerobic tank through the pipeline, and pass through the aeration tube Aeration is carried out continuously for 6 hours; after the aeration treatment, the water in the aerobic tank enters the secondary sedimentation tank through the pipeline for mud-water separation treatment, and the supernatant flows into the first storage tank through the pipeline, and the activated sludge after sedimentation One part is returned to the anaerobic tank by the return pump through the return pipe, and the other part of the remaining activated sludge enters the ozone reactor through the remaining activated sludge pipe; the ozone generated by the ozone generator is introduced into the ozone reactor through the ozone dosing pipe, specifically Introduce 0.05g / g MLSS each...

Embodiment 3

[0052] Pass the sewage into the anaerobic tank through the water inlet pipe, make it stay in the anaerobic tank for 1 hour, then flow into the anoxic tank through the pipeline, stay in the anoxic tank for 2 hours, then flow into the aerobic tank through the pipeline, and pass through the aeration tube Aeration is performed continuously for 8 hours; after the aeration treatment, the water in the aerobic tank enters the secondary sedimentation tank through the pipeline for mud-water separation treatment, and the supernatant flows into the first storage tank through the pipeline, and the activated sludge after sedimentation One part is returned to the anaerobic tank by the return pump through the return pipe, and the other part of the remaining activated sludge enters the ozone reactor through the remaining activated sludge pipe; the ozone generated by the ozone generator is introduced into the ozone reactor through the ozone dosing pipe, specifically Introduce 0.02g / g MLSS each t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com