Device for treating volatile organic gaseous contamination

A volatile organic and gas pollution technology, applied in gas treatment, oxidized water/sewage treatment, membrane technology, etc., can solve the problems of short contact time between oxidants and pollutants, oxidants remaining in exhaust gas, and reduced treatment efficiency, so as to improve Effective utilization rate, reduction of purification degree, and effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

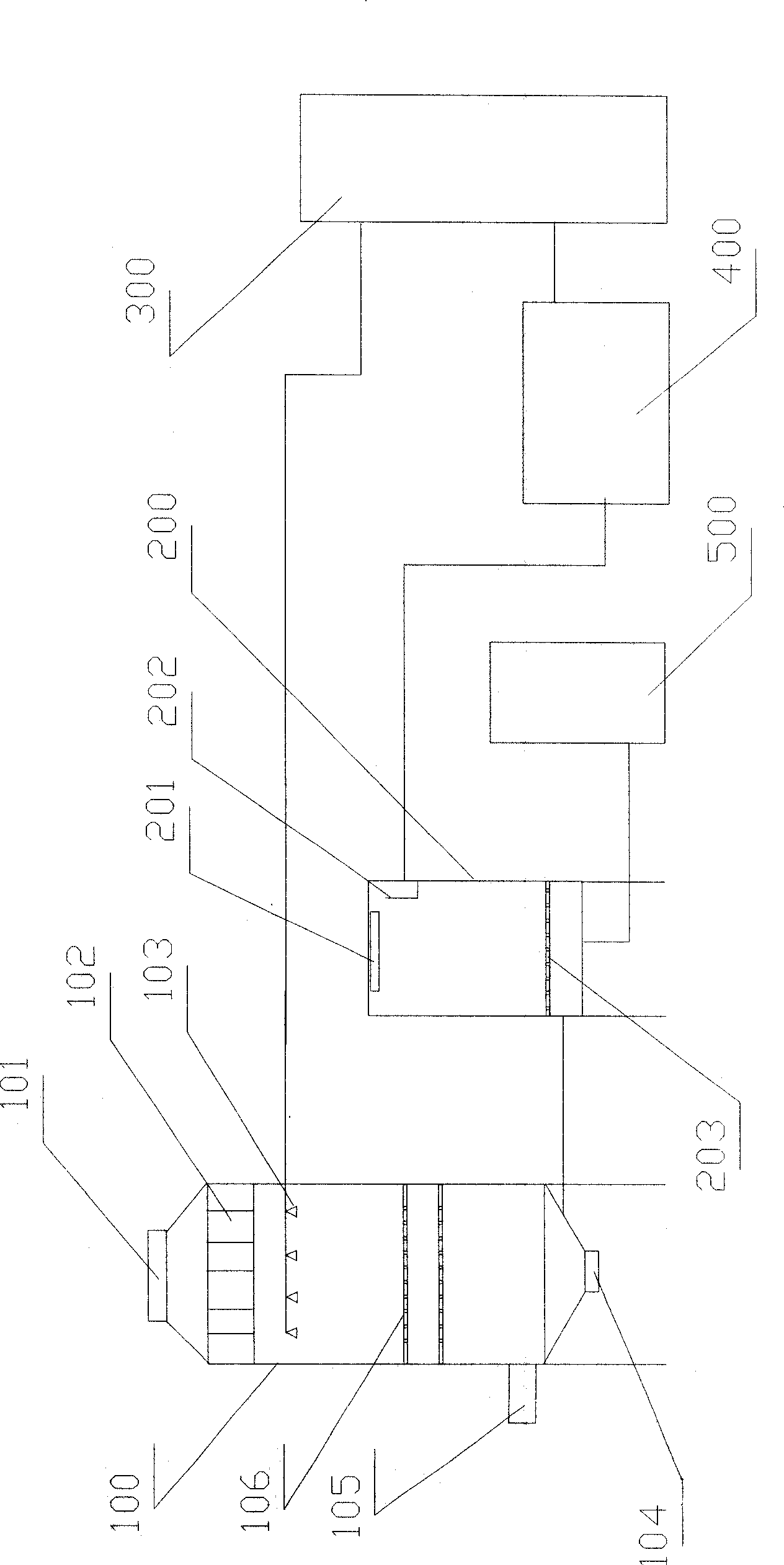

[0007] see figure 1 , a treatment device for volatile organic gas pollution, comprising a washing tower 100, a catalytic oxidation tank 200, a liquid storage tank 300 and an ozone generator 500, the middle part of the inner space of the washing tower is provided with several washing liquid nozzles 103, and the lower part is provided with There are several layers of sieve plates 106, the top is provided with a gas-liquid separation device 102, the air inlet 105 of the washing tower is connected to the tower inner space at the bottom of the sieve plate, and the gas outlet 101 is connected to the gas outlet of the gas-liquid device. Photocatalyst particles are housed in the catalytic oxidation tank, the ozone generator is provided with an ozone contact device that dissolves ozone in water, the nozzle pipeline of the scrubber is connected with the liquid storage tank, and the bottom drain is connected with the catalytic oxidation tank The water inlet at the bottom is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com