Exhaust steam waste heat recycling system for small steam turbine of induced draft fan through circulating water based on steam turbine driving

A technology for small steam turbines and induced draft fans, which is applied in steam engine installations, machines/engines, steam applications, etc., can solve the problems of reduced economic efficiency, reduced main steam turbine work, and exhaust heat loss of induced draft fan steam turbines, and achieves reduction in civil engineering volume. The effect of small size, height reduction and project cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

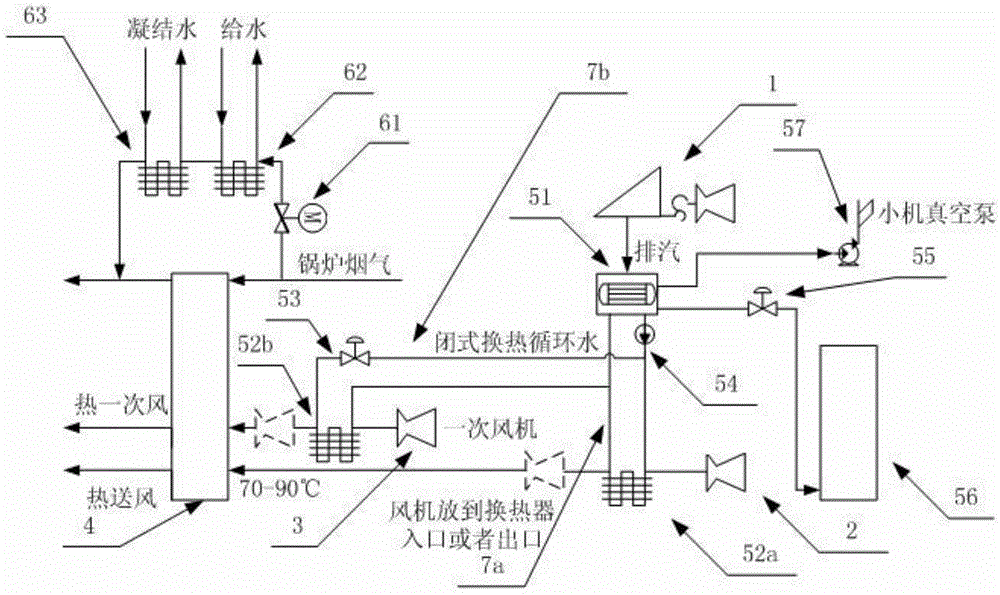

[0019] Embodiment 1 (new coal-fired power plant application)

[0020] The induced draft fan has a large capacity and is driven by steam. For the convenience of starting, an electric start-up induced draft fan with a capacity of 30-50% is set at the same time; the primary fan 3 and the blower fan 2 are electrically driven. When the load of the standby unit rises to 30-50% load, the induced draft fan is switched to the small steam turbine for driving, and the exhaust steam heat of the induced draft fan small steam turbine 1 is heated by the indirect cooling heat exchange system to heat the primary air and the supply air, and recover this part of the exhaust steam heat.

[0021] After the primary air 3 and the supply air 2 are heated by the waste heat of the induced draft fan steam turbine 1, the exhaust gas temperature of the boiler air preheater 4 will inevitably rise. In order to reduce the exhaust gas temperature of the air preheater 4, a bypass feed water heat exchanger 62 a...

Embodiment 2

[0024] Embodiment two (applying to the expansion coal-fired power plant)

[0025] Since there is external auxiliary steam, only the steam-driven induced draft fan can be installed, and the electric start-up induced draft fan can be removed, and the steam-driven induced draft fan can be started directly when the unit is started.

[0026] When recovering the waste heat of the small steam turbine, the exhaust steam of the small steam turbine 1 of the induced draft fan is discharged to the small machine condenser 51, and the condensed water flows into the heat exchanger 52 through the circulating water pipe 7 and the circulating pump 54 to heat the primary air and send Wind; the circulating pump provides circulating power, and the primary air is adjusted according to the actual needs of the system by adjusting the opening of the primary air heat exchange regulating valve 53 to adjust the heat transfer; the air supply recovers most of the heat from the waste heat of the exhaust stea...

Embodiment 3

[0028] Embodiment 3 (Application to technical transformation of in-service air-cooling units)

[0029] For wet-cooled in-service units, there have been examples in China of changing the induced draft fan from electric motor drive to small steam turbine drive. The purpose is to reduce the power consumption rate of the plant and increase the power transmission to the grid. However, for air-cooled units, due to the limited capacity of the air-cooled island and site constraints, it is impossible to use the existing air-cooled island margin or build a new induced draft fan air-cooled island. At present, there is no case of changing the induced draft fan to steam for domestic air-cooled units in service.

[0030] However, the exhaust heat of the small steam turbine 1 of the induced draft fan is led to the heat exchanger 52 of the primary air 3 and the air supply 2 through the indirect cooling heat exchange system, which is to use the fan heat exchanger 52 as an air-cooling device and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com