Method and system for utilizing carbon dioxide and energy of thermal power plant based on plant factory

A carbon dioxide, thermal power plant technology, applied in the fields of botanical equipment and methods, electric light sources, gardening methods, etc., can solve the problems of low energy utilization rate of thermal power plants, reduce power transmission loss, reduce coal consumption for power generation, and improve plant growth conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

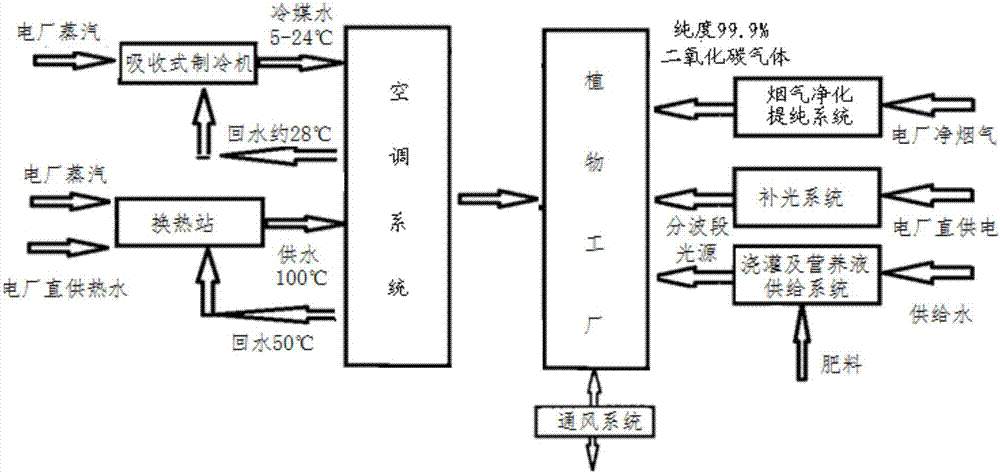

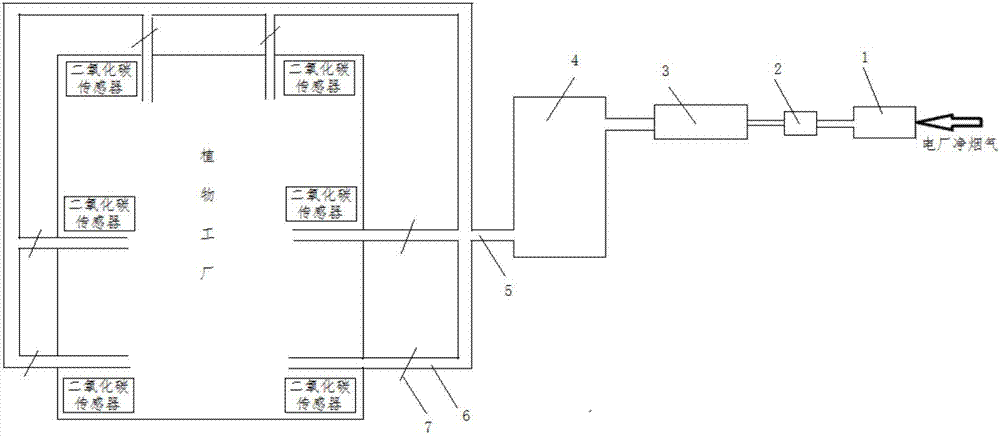

[0024] like figure 1 As shown, the plant factory-based thermal power plant energy and carbon dioxide utilization system in the exhaust gas of the present invention includes a plant factory, a thermal power plant, an absorption refrigerator, a heat exchange station, and a flue gas purification and purification system. The plant factory is equipped with air conditioning system, ventilation system, lighting system, watering and nutrient solution supply system. The absorption chiller adopts the lithium bromide absorption chiller, uses the steam provided by the thermal power plant as the heat source, and the refrigerant water generated is passed into the air-conditioning system of the plant factory through the refrigerant water pipeline. The supplementary light system adopts the LED lamp dot matrix supplementary light system. When the temperature needs to be raised, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com