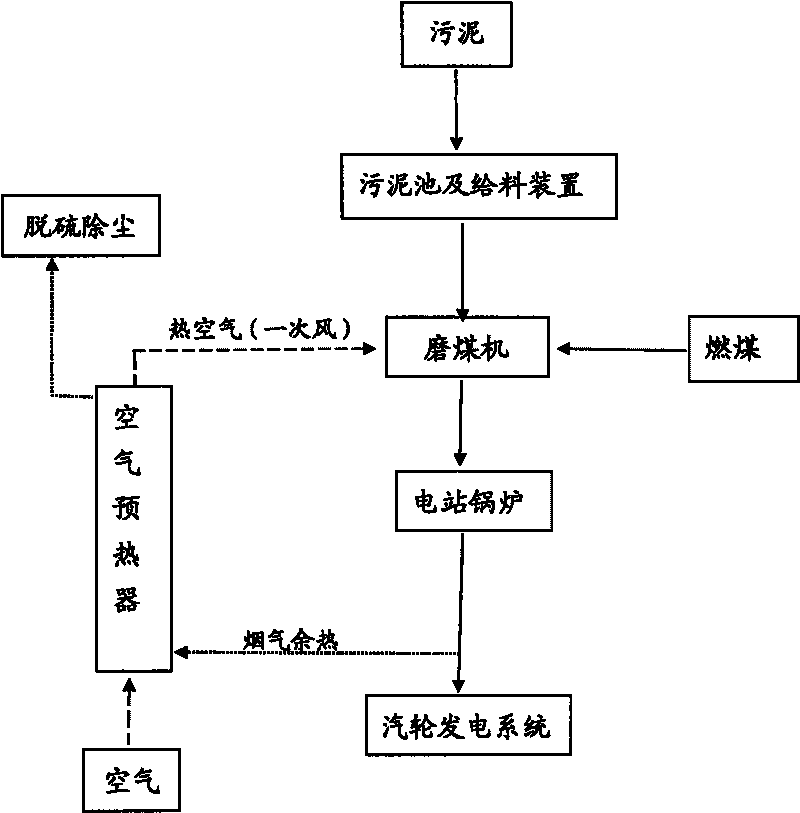

Sludge treatment method for drying sludge by using coal grinding machine and using sludge for electricity generation

A technology for sludge treatment and coal mill, which is applied in dewatering/drying/concentrating sludge treatment, oxidation treatment of sludge, vaporization of by-products, etc., can solve the problems of high moisture content of sludge, complicated process and large investment, etc. Achieve the effect of saving equipment investment, simplifying process and reducing coal consumption for power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

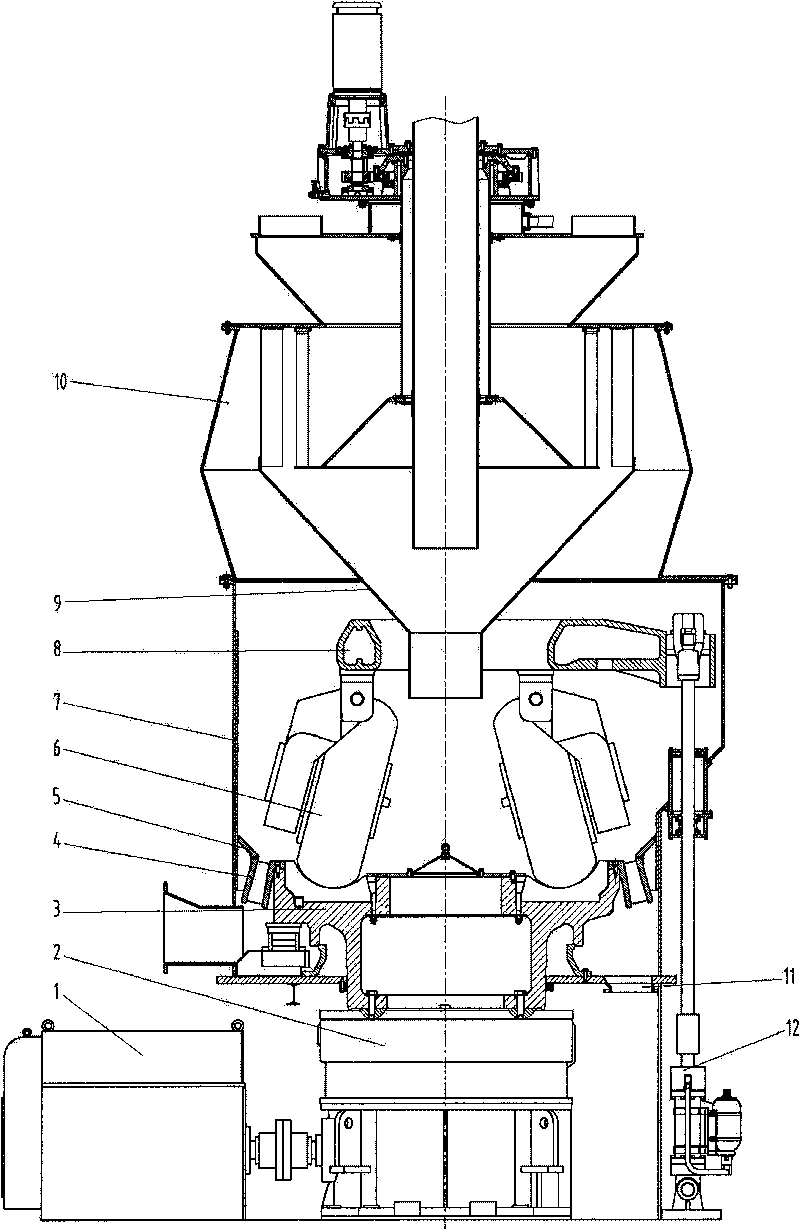

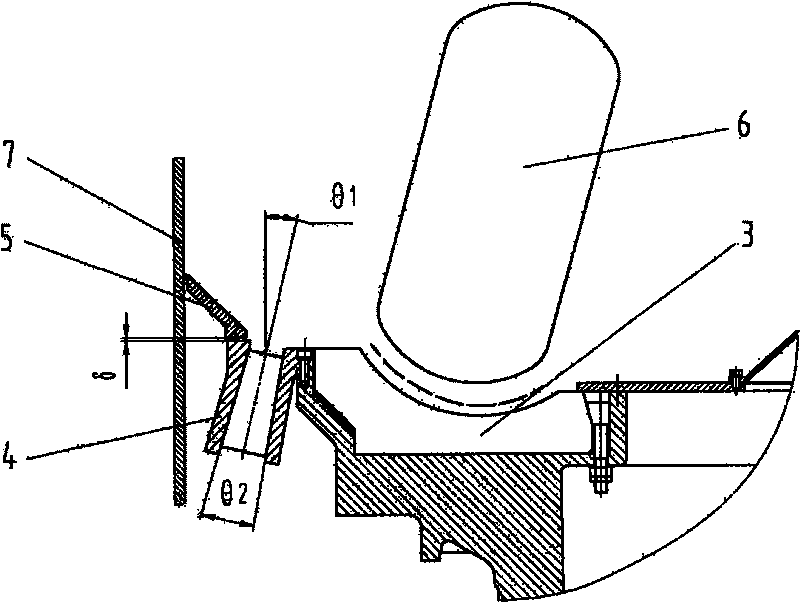

Embodiment 1

[0034] In a power plant with an installed capacity of 300MW, the coal pulverizer adopts the 4+1 operation mode, with 4 running and 1 standby. The output of the original single coal pulverizer is 36 tons / hour, and the single coal pulverizer can treat wet sewage with a moisture content of 70% every day The mud capacity is 70 tons, and 280 tons of wet sludge is treated as an example every day to illustrate the specific implementation method of the present invention. After transporting 280 tons / day of raw wet sludge to the power plant, store it in the sludge tank, transport it to the upper part of the coal mill through metering pumps and pipelines, and use the sludge feeder to introduce the sludge into the coal mill. The amount added is 8% of the raw coal (about 2.9 tons / unit.hour). The waste heat of the flue gas from the power plant boiler exchanges heat with the air introduced by the fan through the air preheater, and the generated primary air at 260°C is directly blown into the...

Embodiment 2

[0036]For a power plant with an installed capacity of 200MW, the coal pulverizer adopts the 4+1 operation mode, 4 units are in operation and 1 is used as a backup. The output of the original single coal pulverizer is 25 tons / hour, and the daily water content of a single coal pulverizer is 75% of the total weight. Take 42 tons of sludge, and treat 168 tons of wet sludge every day as an example to illustrate the specific implementation method of the present invention. After transporting 168 tons / day of raw wet sludge to the power plant, store it in the sludge tank, transport it to the upper part of the coal mill through metering pumps and pipelines, and use the sludge feeder to introduce the sludge into the coal mill. The amount added is 7% of the weight of raw coal (about 1.75 tons / unit.hour). The waste heat of the flue gas from the boiler in the power station exchanges heat with the air introduced by the fan through the air preheater, and the generated primary air at 260°C is ...

Embodiment 3

[0038] In a power plant with an installed capacity of 135MW, the coal mill adopts 3+1 operation mode, with 3 running and 1 standby. The output of the original single coal mill is 20 tons / hour, and the daily water content of a single coal mill is 85% of the total weight. Take 24 tons of sludge, and treat 72 tons of sludge every day as an example to illustrate the specific implementation method of the present invention. After transporting 72 tons / day of wet sludge to the power plant, store it in the sludge tank, transport it to the upper part of the coal mill through metering pumps and pipelines, and use the sludge feeder to introduce the sludge into the coal mill. The addition of sludge The amount is 5% of the raw coal (about 1.0 tons / unit.hour). The waste heat of the flue gas from the power plant boiler exchanges heat with the air introduced by the fan through the air preheater, and the generated primary air at 260°C is directly blown into the coal mill as a drying heat source...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com