Power source automatic assembly production line and assembly process thereof

A technology of automatic power supply and production line, which is applied in the direction of assembly machines, auxiliary devices, manufacturing tools, etc., and can solve problems such as high product failure rate, long production line, low production efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

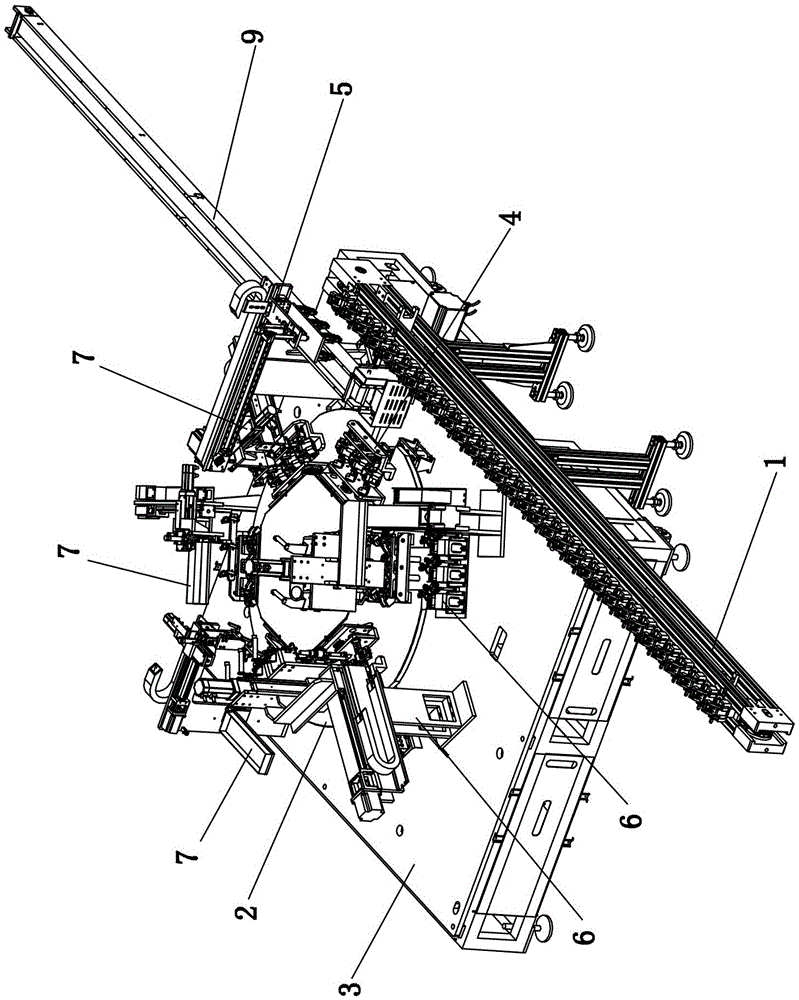

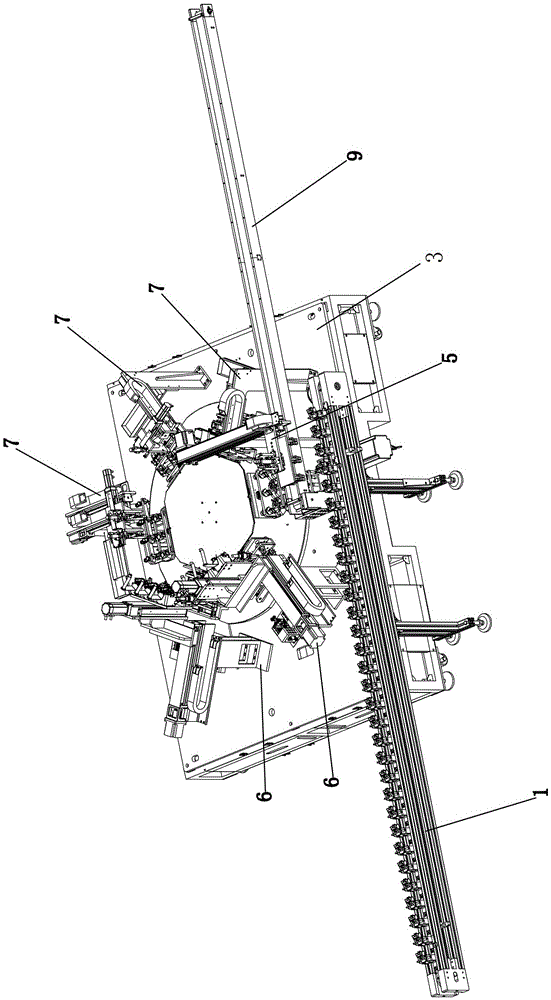

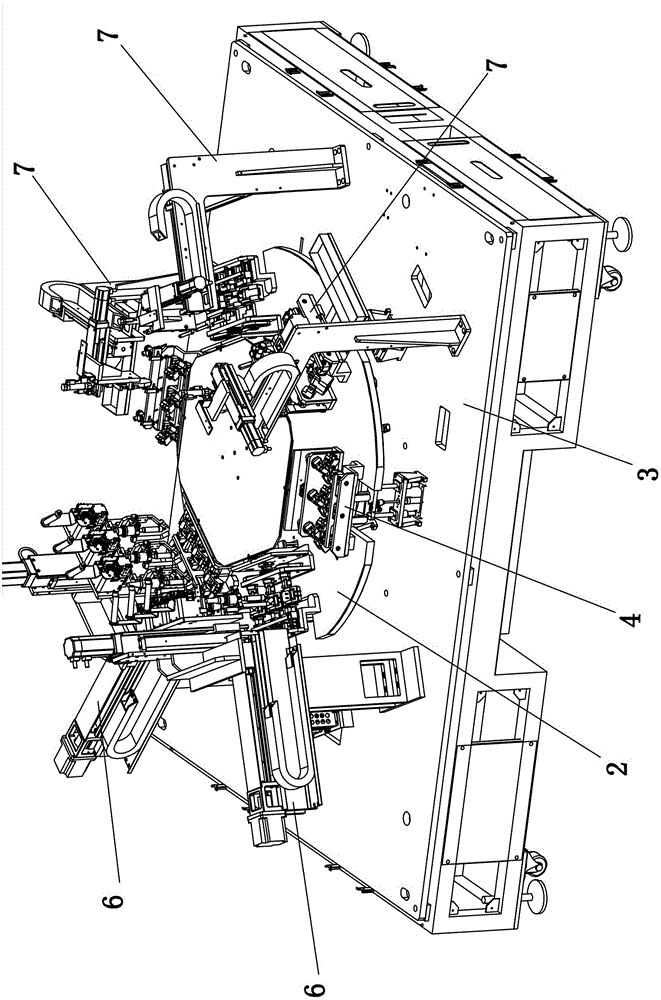

[0052] The present invention will be further described below in conjunction with accompanying drawing:

[0053] Such as Figure 1 to Figure 22 As shown, the technical solution adopted by the present invention is as follows: an automatic power supply assembly production line, including a feeding mechanism 1, an assembly platform 2, a material carrying mechanism 5, a welding mechanism 6, a glue dispensing mechanism 7 and a material discharging mechanism 9, wherein the above-mentioned The feeding mechanism 1 and the discharging mechanism 9 are respectively arranged on both sides of the assembly platform 2, the feeding mechanism 1 extends to the outside of the assembly platform 2, and transports the jig 04 loaded with the power supply 05 forward to the assembly platform 2 one by one The middle part of the above-mentioned assembly platform 2 is provided with a turntable 21, and the edge of the turntable 21 is provided with a loading and unloading station 4 and at least two processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com