Paper cup or paper bowl packaging line

A packaging line and paper cup technology, applied in the field of improvement and invention, can solve the problems of low efficiency, many production personnel, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

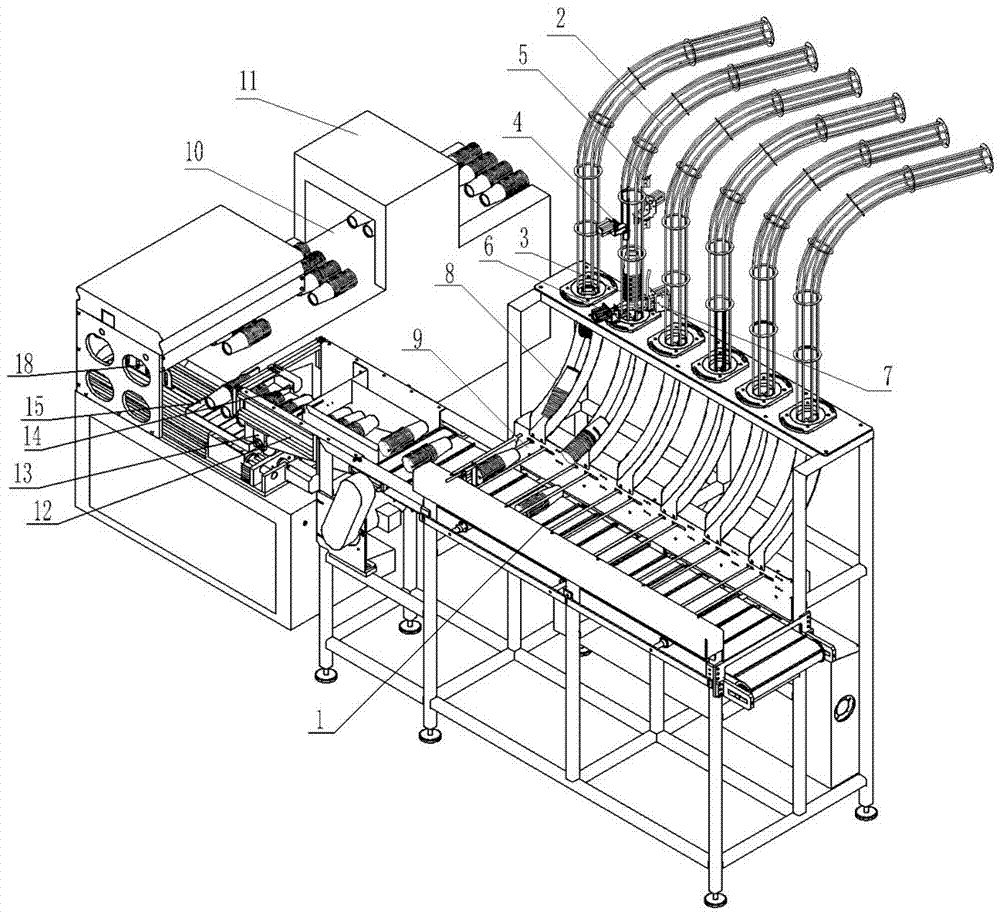

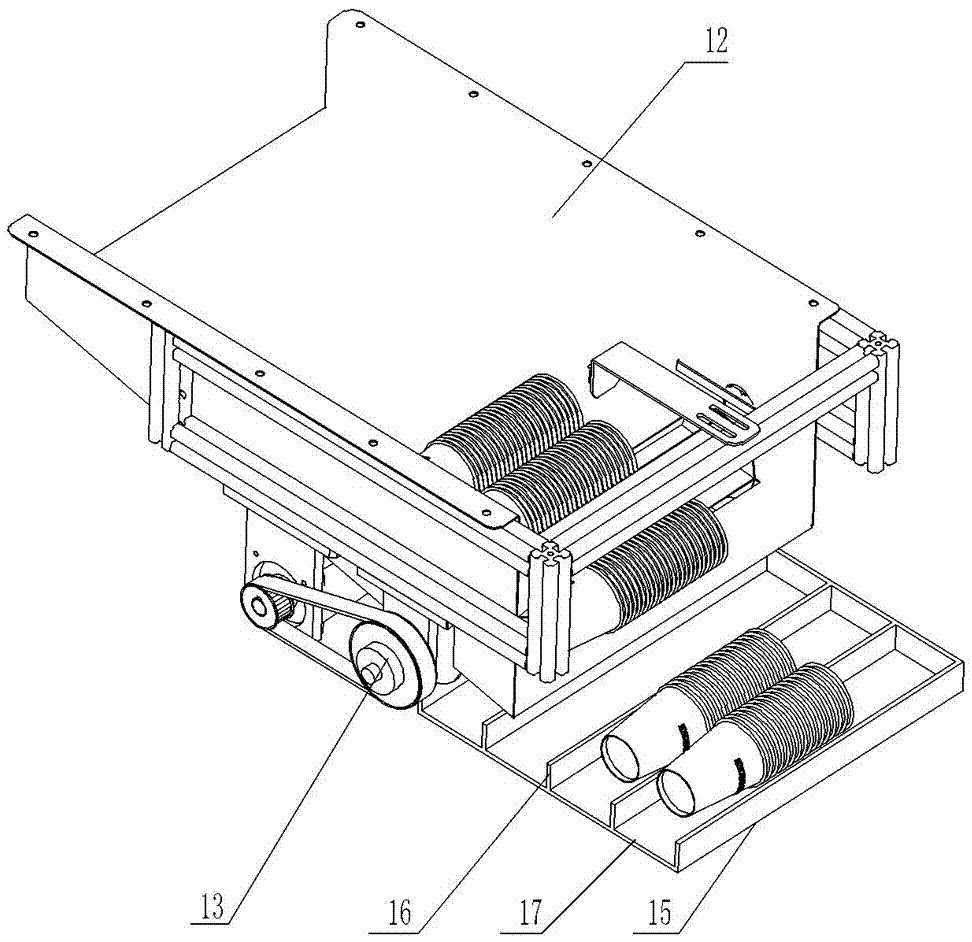

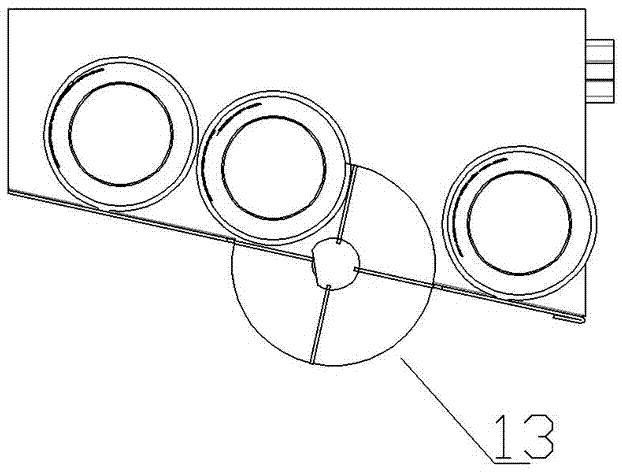

[0021] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The paper cup or paper bowl packaging line includes a collecting device and a packaging conveying device. The collecting device includes a first conveying platform 1 and a cup collection pipeline 2. The cup collection pipeline 2 is connected to the paper cup forming outlet of the paper cup machine, and the cup collection pipeline 2 is set There are at least two, respectively connected to a corresponding number of paper cup machines, the first conveying table 1 is preferably a synchronous belt or a roller chain: the cup collecting pipeline 2 includes a paper cup stacking area 3, and a first Cup blocking mechanism 4 and counter 5, counter 5 is arranged on the top of first blocking mechanism 4, and counter 5 is preferably photoelectric counter 5, and paper cup stacking area 3 lower end is provided with second block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com