Fruit quality real time detection and grading robot system

A robotic system and real-time detection technology, applied in the field of robotic systems, can solve problems such as failure to complete simultaneously, slow speed, high missed detection rate of fruit surface, etc., to achieve the effect of improving competitiveness and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

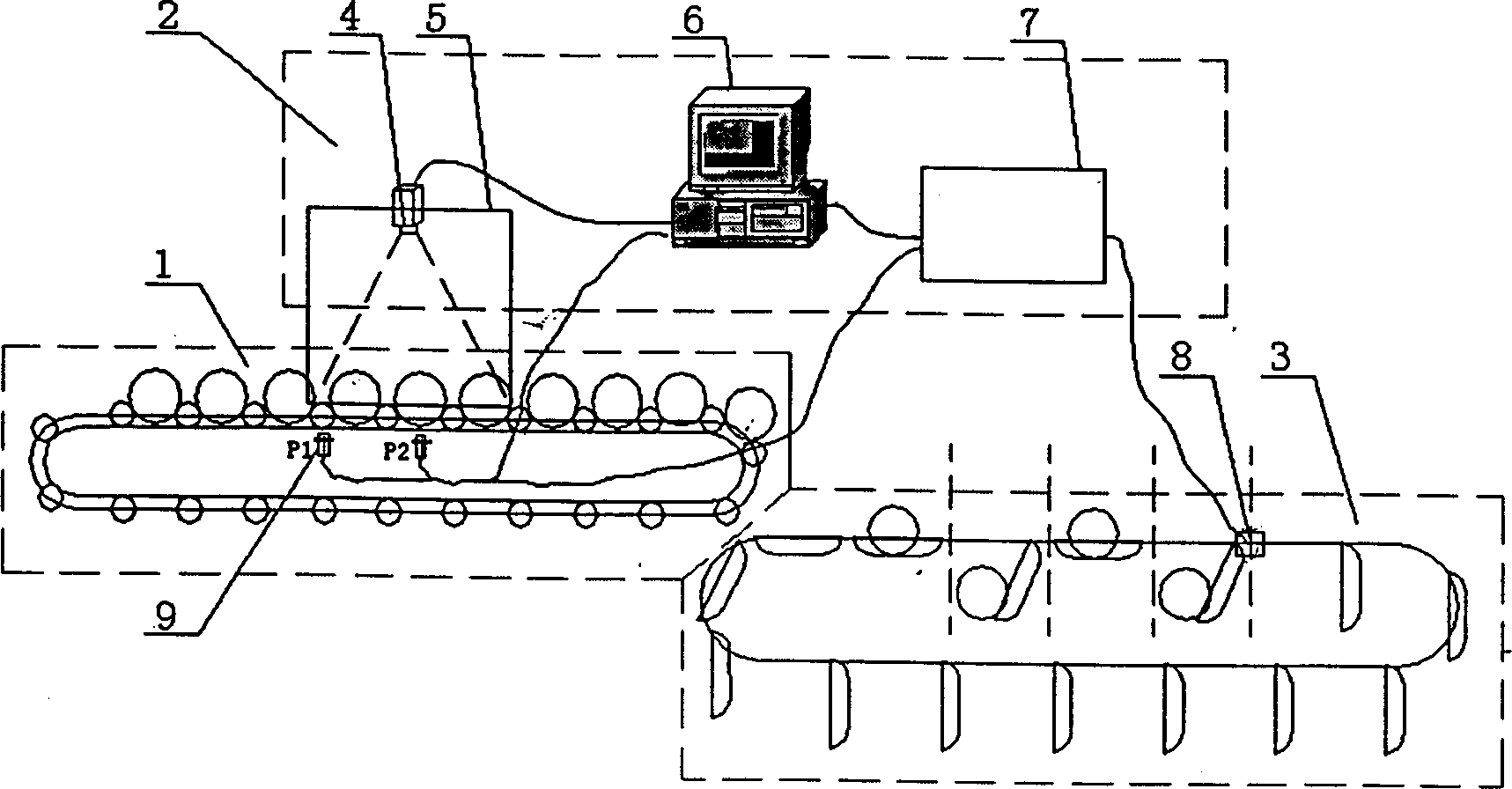

[0019] like figure 1 Shown, the present invention is made up of fruit conveying overturning part 1, computer vision identification part 2 and fruit grading part 3.

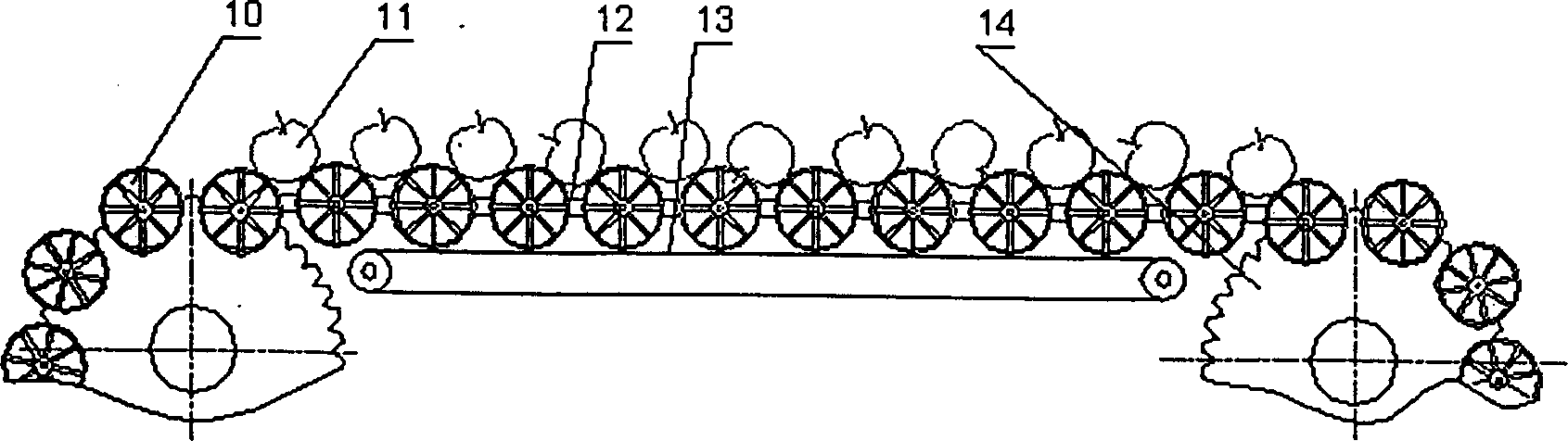

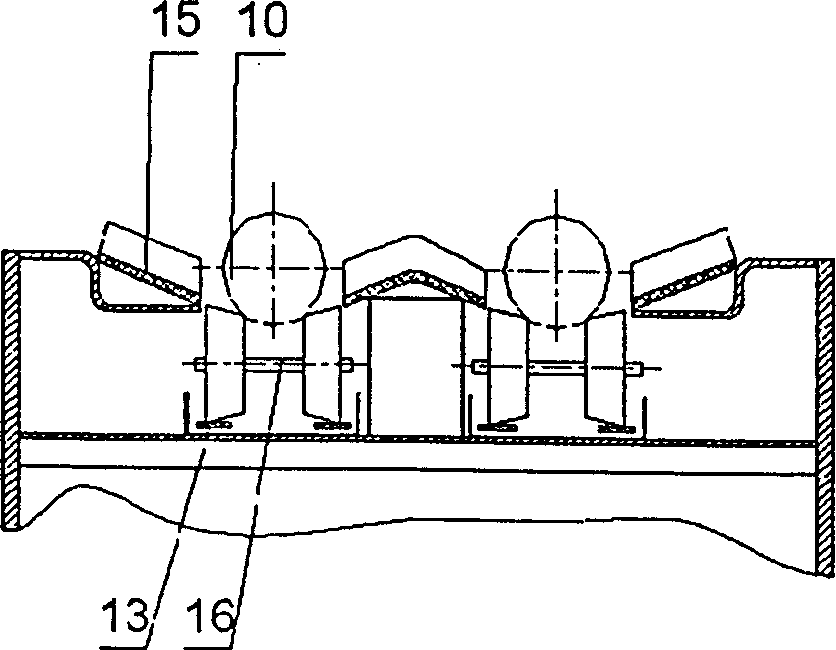

[0020] like figure 1 , figure 2 , image 3 As shown, the fruit conveying turning part 1: includes double-cone roller 10, conveying chain 12, friction belt 13, conveying sprocket 14, slope plate 15, horizontal small shaft 16; double-conical roller 10 passes through the horizontal small shaft 16 is evenly installed on the conveyor chain 12, the conveyor sprocket 14 rotates, the double-cone roller 10 can move forward with the conveyor chain 12, and the friction belt 13 installed under the double-cone roller 10 is driven by another motor. When there is a speed difference between the two, the double-cone roller 10 will rotate around the small horizontal axis 16 on the friction belt 13, and the two sides of the double-cone roller 10 are provided with a ribbed slope plate 15, and the slope plate 15 The lowest end is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com