Multiple inspection robot cooperative operation method for substation sequence control system

A technology for inspection robots and substations, applied in two-dimensional position/channel control, etc., can solve the problems of insufficient substation layout, inability to achieve full coverage of equipment, and not involving substations and sequence control systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present invention will be further described below in combination with specific embodiments.

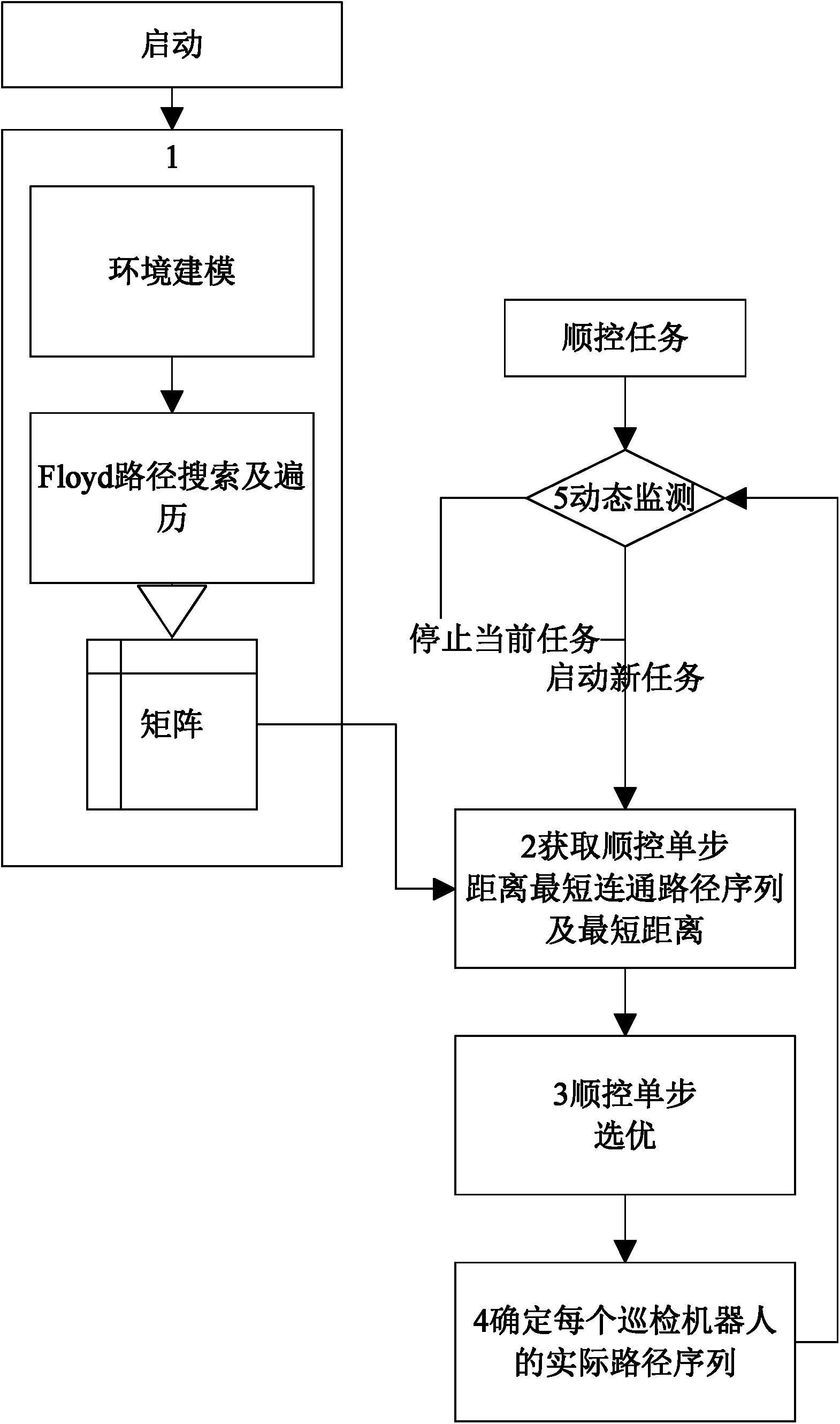

[0072] figure 1 Among them, a multi-inspection robot collaborative operation method for substation sequence control system, its steps are:

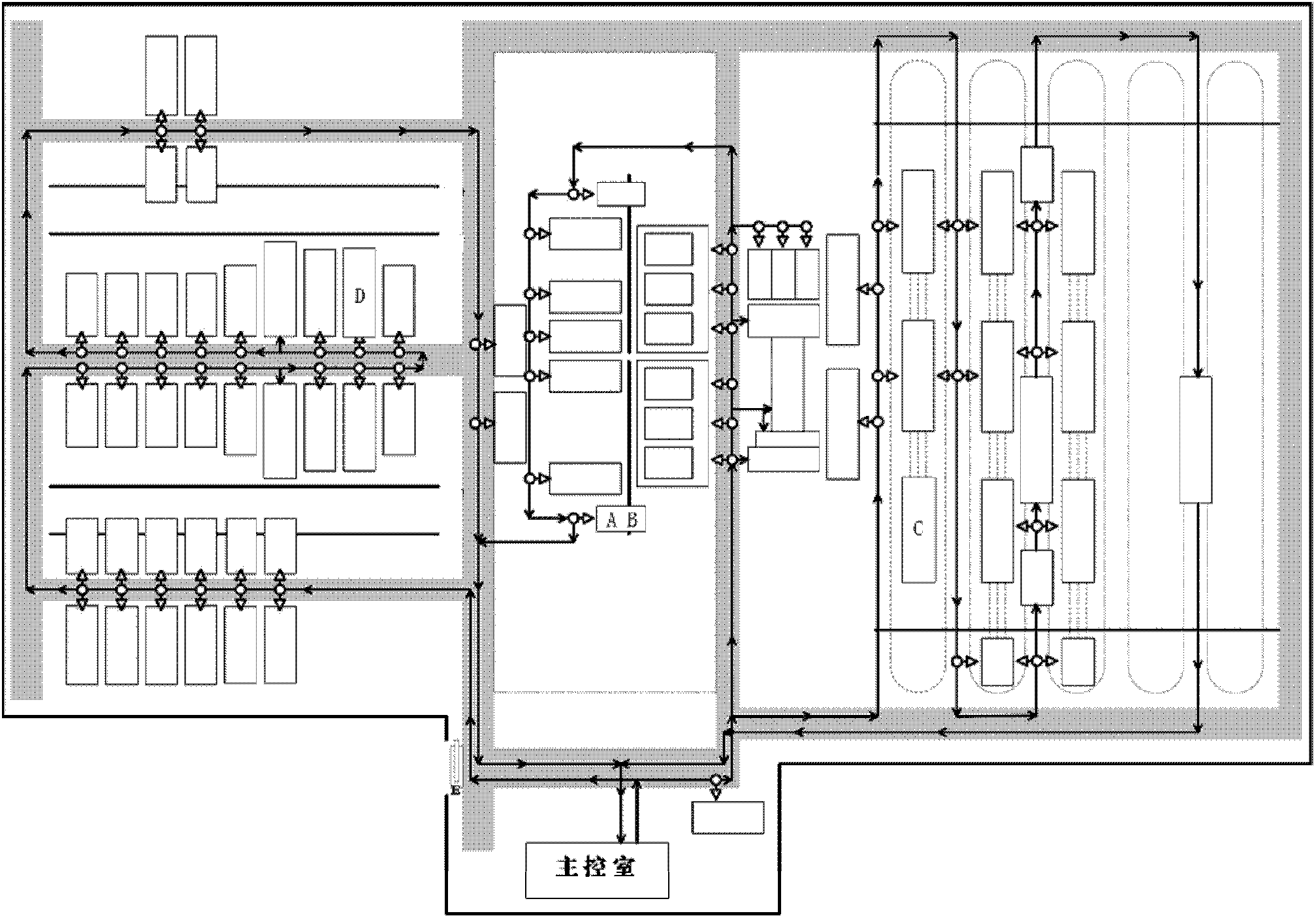

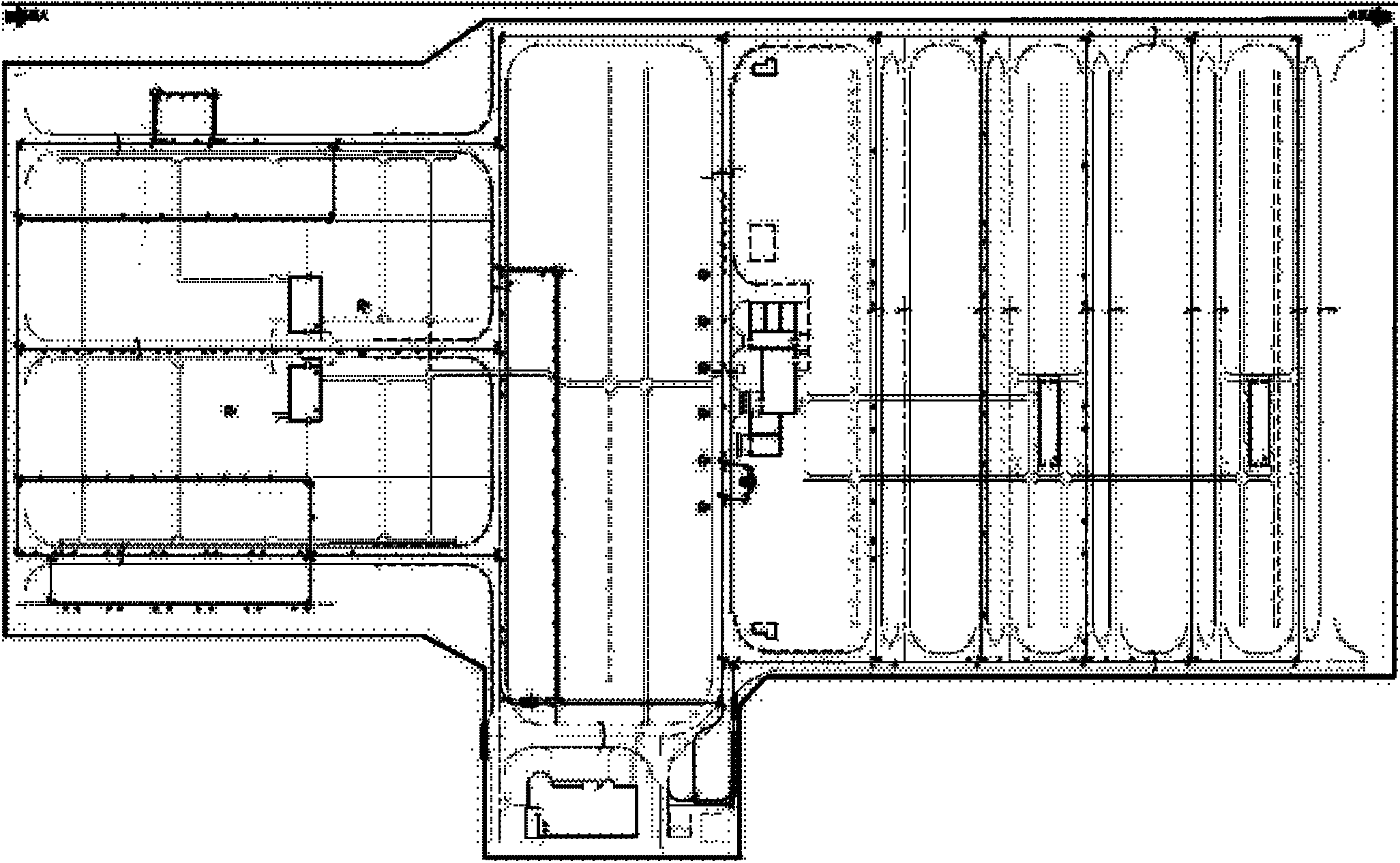

[0073] The first step is to use topology modeling based on the substation environment, and form a topology network graph and a connectivity matrix according to the walkable magnetic navigation route of the inspection robot, search for the path and traverse the output distance matrix and shortest path matrix;

[0074] The second step is to determine the shortest connected path sequence of each inspection robot from the current position to the target point according to the distance matrix and the shortest path matrix during the sequential control single step;

[0075] The third step is single-step selection of each target point, that is, selecting the inspection robot with the best performance under the comprehensive indicators of dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com