Handling and calibrating manipulator

A technology of manipulator and installation and calibration, applied in the field of manipulator, can solve the problem of inability to precisely fine-tune the posture of the object to be loaded, and achieve the effects of simple structure, high positioning accuracy and high automation level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

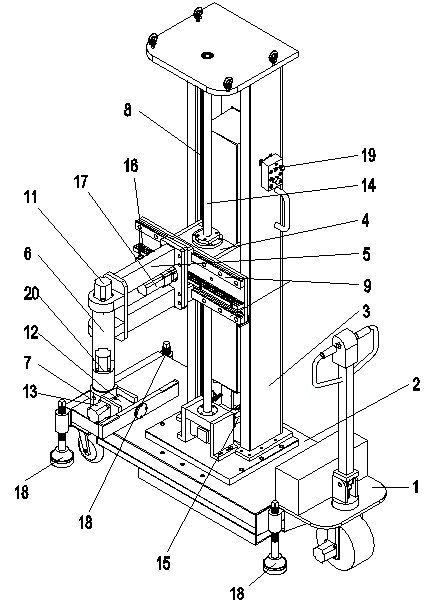

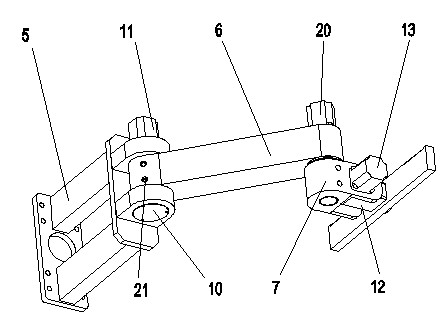

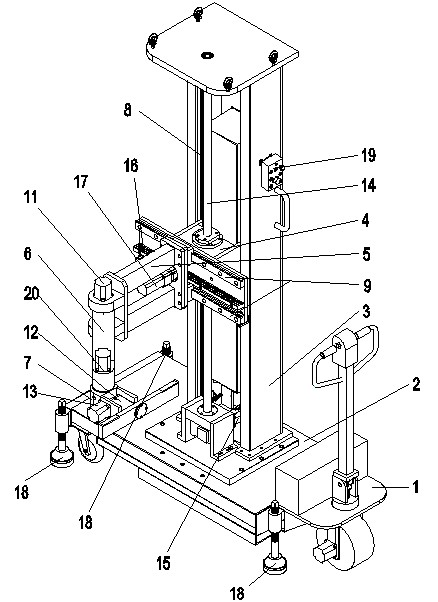

[0015] Such as figure 1 The illustrated loading and transporting manipulator is composed of an electric platform car 1, a lifting platform 2, a frame 3, a moving frame 4 up and down, a moving frame 5 left and right, a rotating arm 6, and a front end actuator 7. Wherein the frame 3 is vertically fixed on the lifting platform 2, and the electric platform vehicle 1 has the functions of electric walking and electric lifting. The frame 3 is provided with an up and down moving guide rail 8, and the frame 3 and the up and down moving frame 4 are connected by the up and down moving guide rail 8, and the up and down moving guide rail 8 guides the sliding of the up and down moving frame 4 on the frame 3; the front end of the up and down moving frame 4 Horizontal guide rail 9 is provided, and up and down movable frame 4 and left and right movable frame 5 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com