Method for producing milk product

A dairy product and milk technology, applied in dairy products, milk preparations, food preparation, etc., can solve problems such as inability to produce, adverse reactions, and lower product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

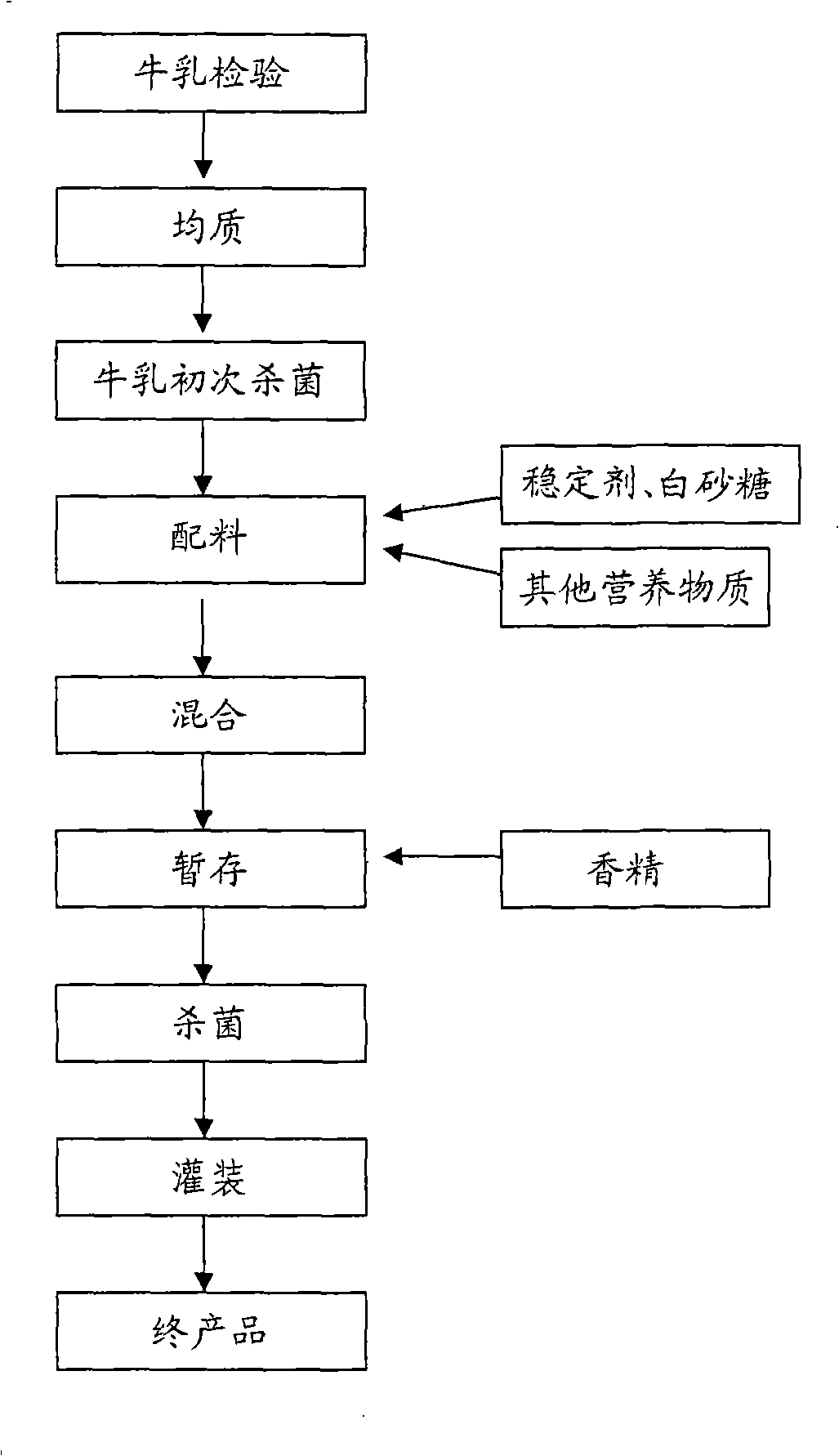

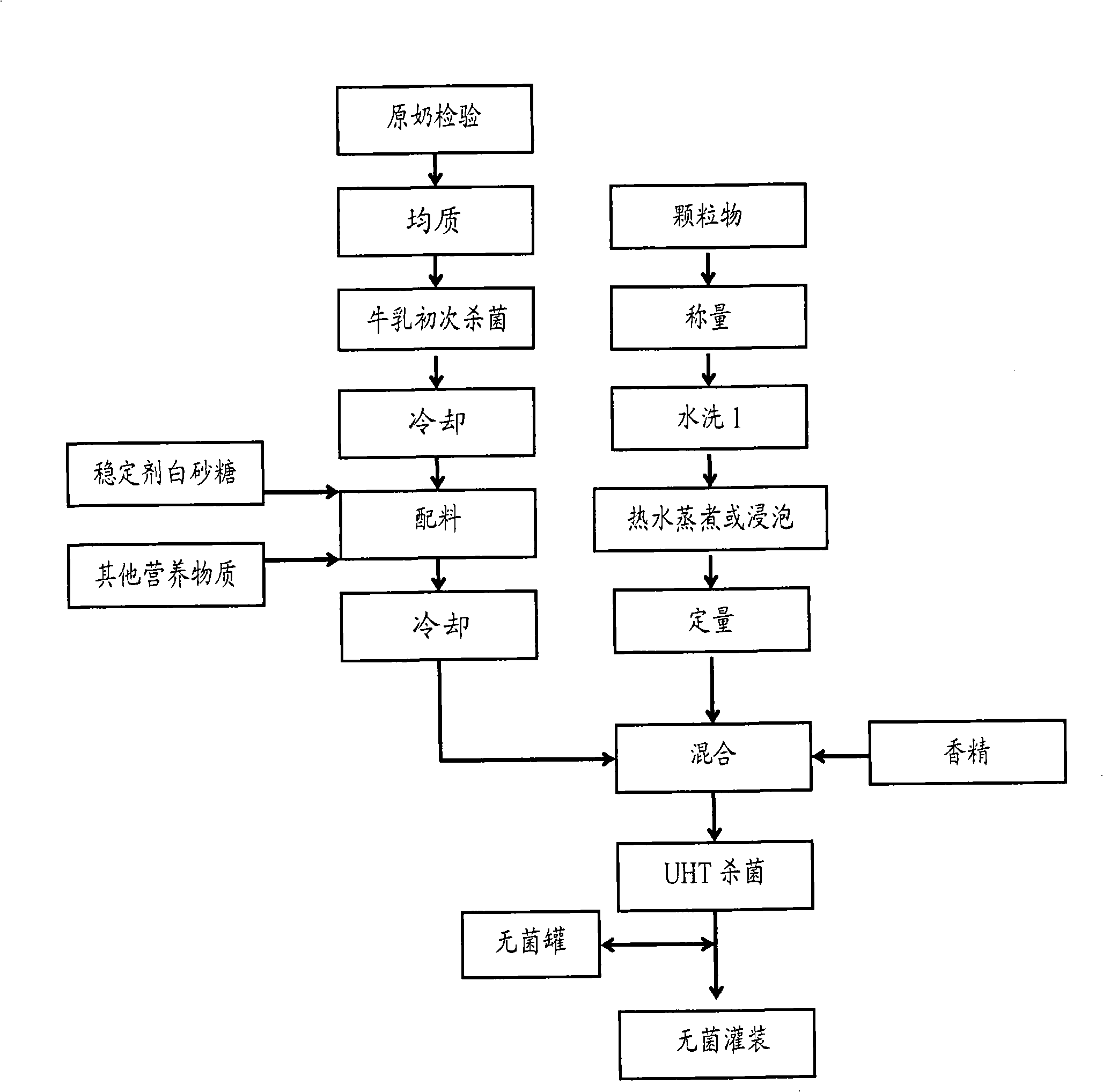

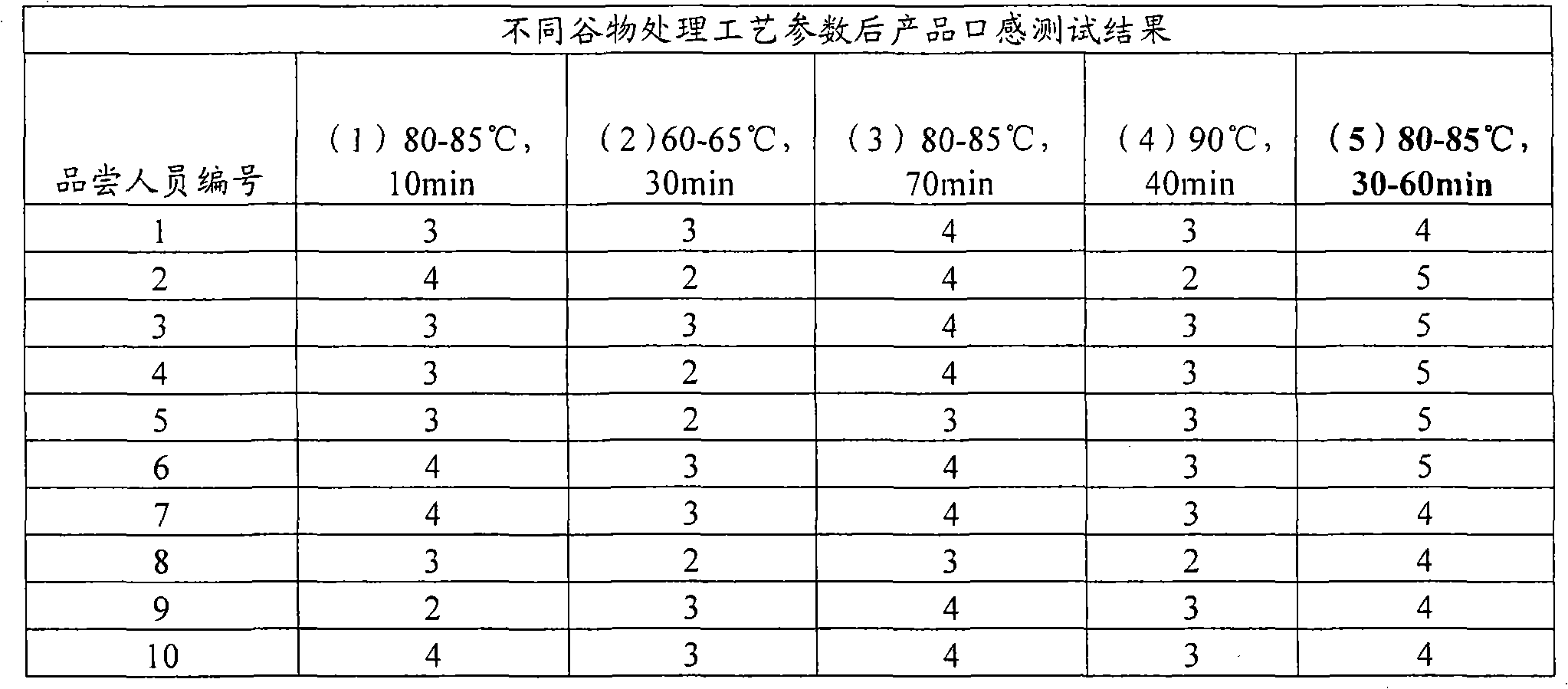

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, produce the milk product containing oat functional granule

[0048] Formula (according to 1 ton):

[0049] Milk 800.0 kg Monoglyceride: 1.5 kg Oats (grain size 5mm): 35 kg White sugar: 35 kg

[0050] Purified water: 128.5 kg

[0051] Preparation Process:

[0052] 1. Inspection of milk

[0053] a. Raw milk inspection: mainly for sensory indicators, acidity, fat, protein, whole milk solids, adulteration, alcohol test and other indicators to ensure that the raw milk meets the relevant national standards.

[0054] b. Milk collection, filtration, and cooling: the raw milk is filtered to remove some large impurities, and the collected fresh milk is cooled to 1°C to 8°C through plate replacement, and stored in raw milk tanks.

[0055] 2. Initial sterilization:

[0056] a. Preheat the milk to 55-65°C.

[0057] b. Homogeneous: The homogeneous pressure is 19MPa, the primary pressure is 13Mpa, and the secondary pressure is 6Mpa.

[0058] c. Pasteurization: The...

Embodiment 2

[0073] Embodiment 2, the production of milk products containing oats and black rice compound functional granules

[0074] Formula (according to 1 ton):

[0075] Milk 360.0kg Monoglycerides: 1.5kg Oats (5-7mm in size): 20kg Black rice (5-6mm in size): 15kg White sugar: 35kg Purified water: 568.5kg

[0076] Preparation Process:

[0077] 1. Inspection of milk

[0078] a. Raw milk inspection: mainly for sensory indicators, acidity, fat, protein, whole milk solids, adulteration, alcohol test and other indicators to ensure that the raw milk meets the relevant national standards.

[0079] b. Milk collection, filtration, and cooling: the raw milk is filtered to remove some large impurities, and the collected fresh milk is cooled to 1°C to 8°C through plate replacement, and stored in the raw milk tank.

[0080] 2. Initial sterilization:

[0081] a. Preheat the milk to 55-65°C.

[0082] b. Homogeneous: The homogeneous pressure is 19MPa, the primary pressure is 13Mpa, and the second...

Embodiment 3

[0098] Example 3. Production of milk products containing buckwheat functional granules

[0099] Formula (according to 1 ton):

[0100] Milk 800.0 kg Monoglyceride: 1.5 kg Buckwheat (grain size 4-5mm): 35 kg White sugar: 35 kg

[0101] Purified water: 128.5 kg

[0102] Preparation Process:

[0103] 1. Inspection of milk

[0104] a. Raw milk inspection: mainly for sensory indicators, acidity, fat, protein, whole milk solids, adulteration, alcohol test and other indicators, which meet the relevant national standards.

[0105] b. Milk collection, filtration, and cooling: the raw milk is filtered to remove some large impurities, and the collected fresh milk is cooled to 1°C to 8°C through plate replacement, and stored in the raw milk tank.

[0106] 2. Initial sterilization:

[0107] a. Preheat the milk to 55-65°C.

[0108] b. Homogenize the milk: the homogenization pressure is 19MPa, the primary pressure is 13Mpa, and the secondary pressure is 6Mpa.

[0109] c. Pasteurizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com