Vertical conveyance device

A technology for handling devices and moving rails, which is applied in the fields of transportation and packaging, electrical components, semiconductor/solid-state device manufacturing, etc. It can solve the problems of lifting height limitation of rack-type lifting devices, reduced handling efficiency, low efficiency, etc., and achieves simple structure, Improvement of handling efficiency and expansion of production scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

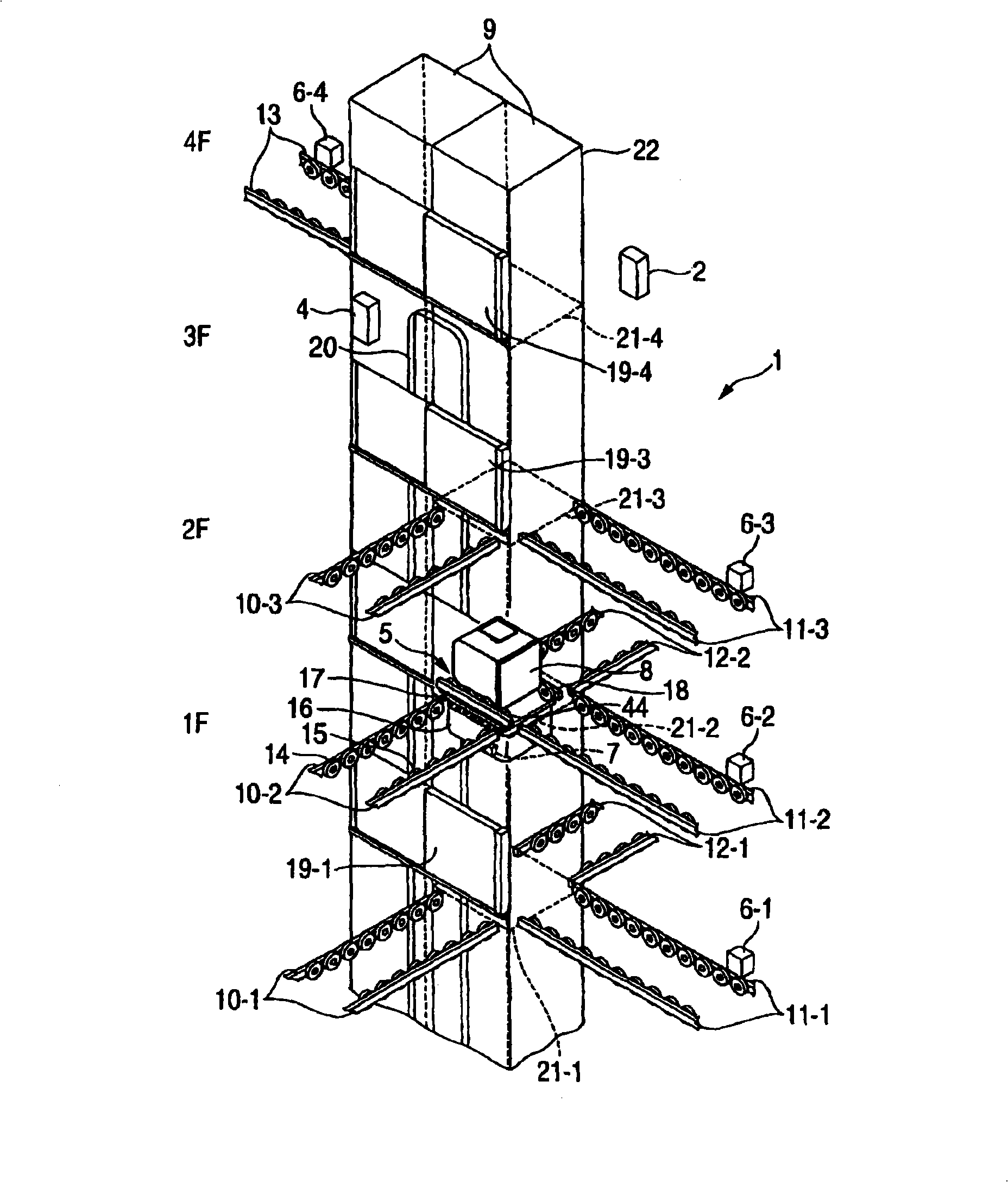

[0044] Hereinafter, an example of a specific best mode for implementing the vertical transfer device according to the present invention will be described with reference to the drawings. It should be noted that the present embodiment can be assumed to be applied to a case where a conveyor system using roller conveyors laid on multiple floors is used in a semiconductor manufacturing plant in which manufacturing processes span multiple floors.

[0045] Below, according to figure 1 The vertical transfer device according to this embodiment will be described. figure 1 It is a perspective view showing the vertical transfer device according to this embodiment.

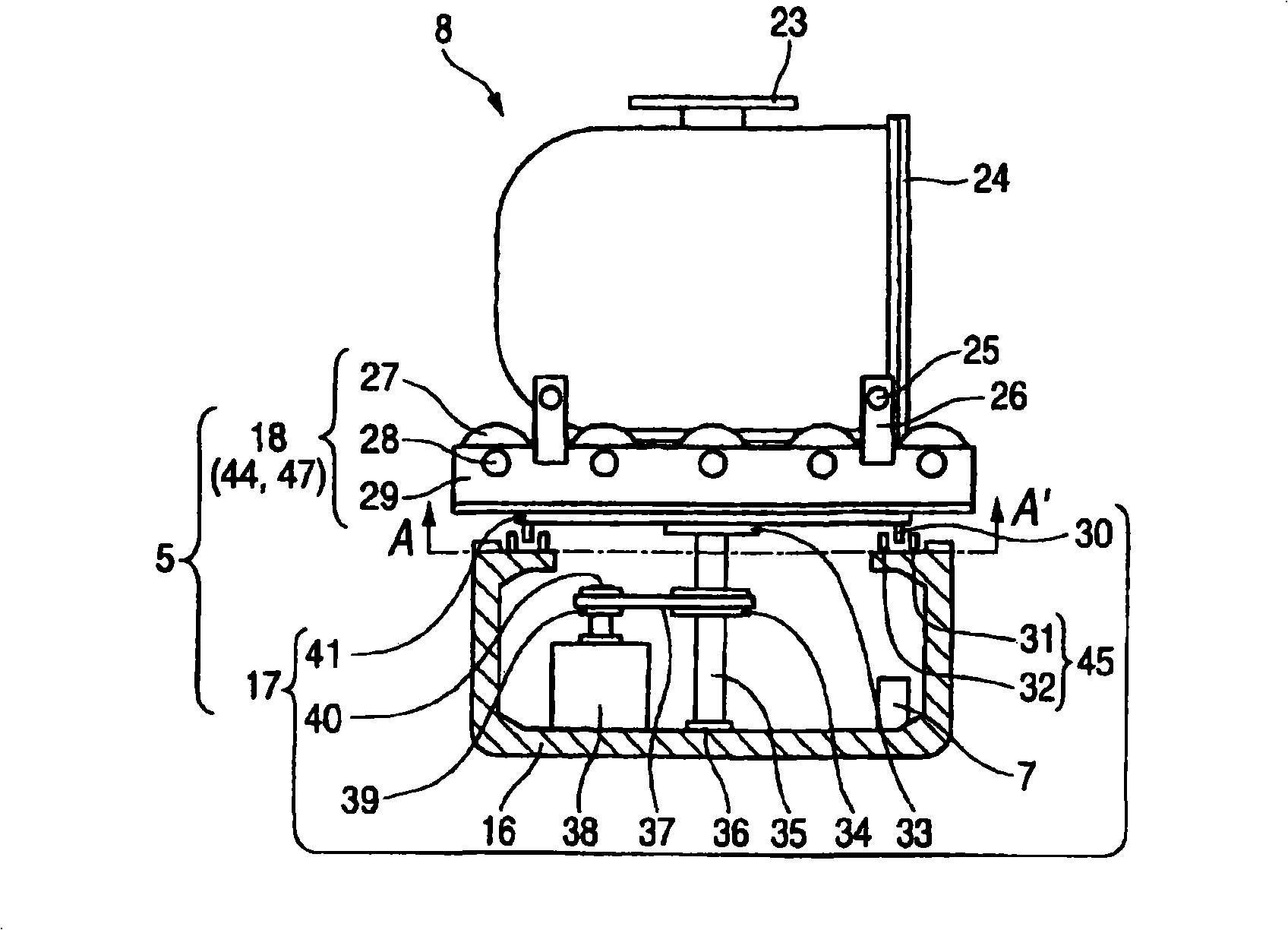

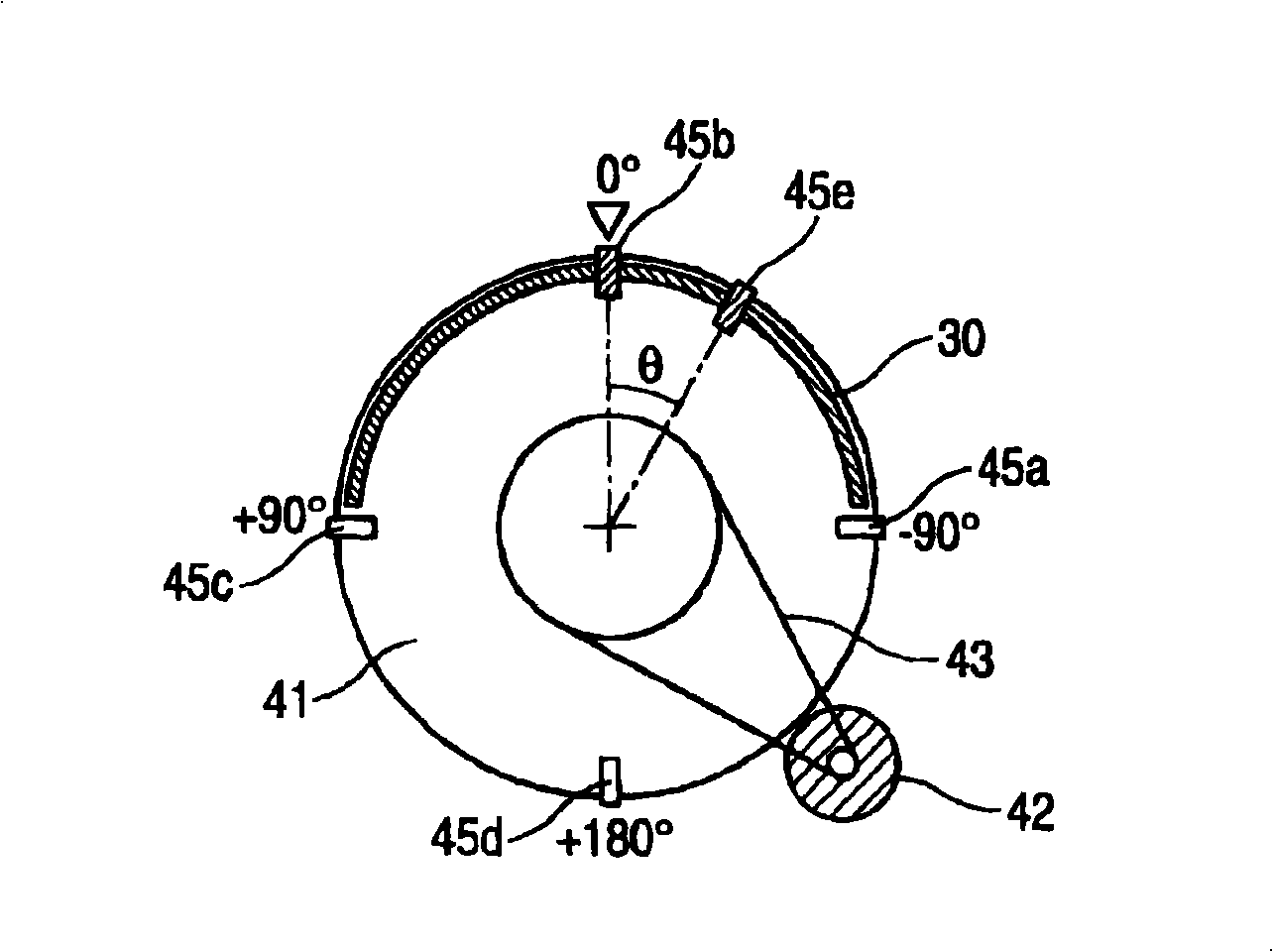

[0046] Such as figure 1 As shown, the vertical conveying device 1 has a lifting conveyor (carrying direction setting device) 5, a cable support lifting device) 20, including a lifting controller 4 and a rotary platform controller 7 ( figure 2 ) vertical transfer controller (vertical transfer control device) 3. and, figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com