Coal-based direct reduced iron shaft furnace

A reduced iron, direct technology, applied in the field of shaft furnace, coal-based direct reduced iron shaft furnace, can solve the problems of uneven heating of pellets, low discharge efficiency, low degree of automation, etc., achieve oxidation resistance heat transfer effect, improve Yield, production efficiency, and effect of improving heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

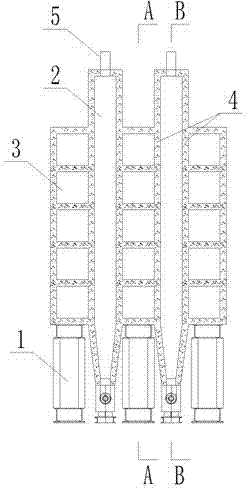

[0034] In the coal-based direct reduction iron shaft furnace of the present invention, the furnace body is integrally erected on the supporting steel structure 1, and the furnace body is provided with two reduction chambers 2 and three combustion chambers 3, the reduction chamber 2 and the combustion chamber 3 The heat conduction wall 4 is arranged at intervals to form a combustion chamber 3 on both sides of the reduction chamber 2, and a combustion chamber 3 is shared between the two reduction chambers 2 (such as figure 1 shown), the shown heat conduction wall 4 is made of high alumina bricks and silicon carbide bricks.

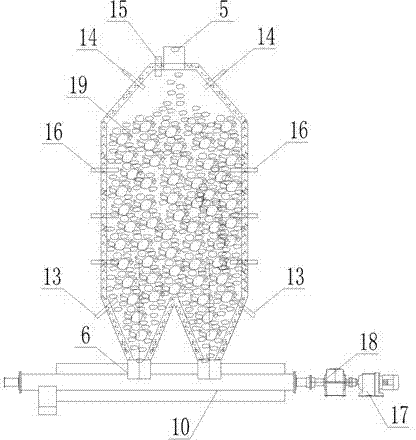

[0035] The upper part of the reduction chamber 2 is provided with a sealed feed port 5, the sealed feed port 5 is a high-temperature-resistant chute, and a pellet with a plug-in baffle structure is also arranged between the sealed feed port 5 and the reduction chamber 2. Cutting device (not shown in the figure), the inner top of the reduction chamber 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com