Guide device for rolling over the barrel wall of oil barrel

A guide device, barrel wall technology, applied in storage devices, feeding devices, positioning devices, etc., can solve the problems of increasing manufacturing costs, increasing scrap rate, and the two sides of the square plate are not parallel to the forward direction, so as to reduce and Scrap rate, small pitch, easy to tighten the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

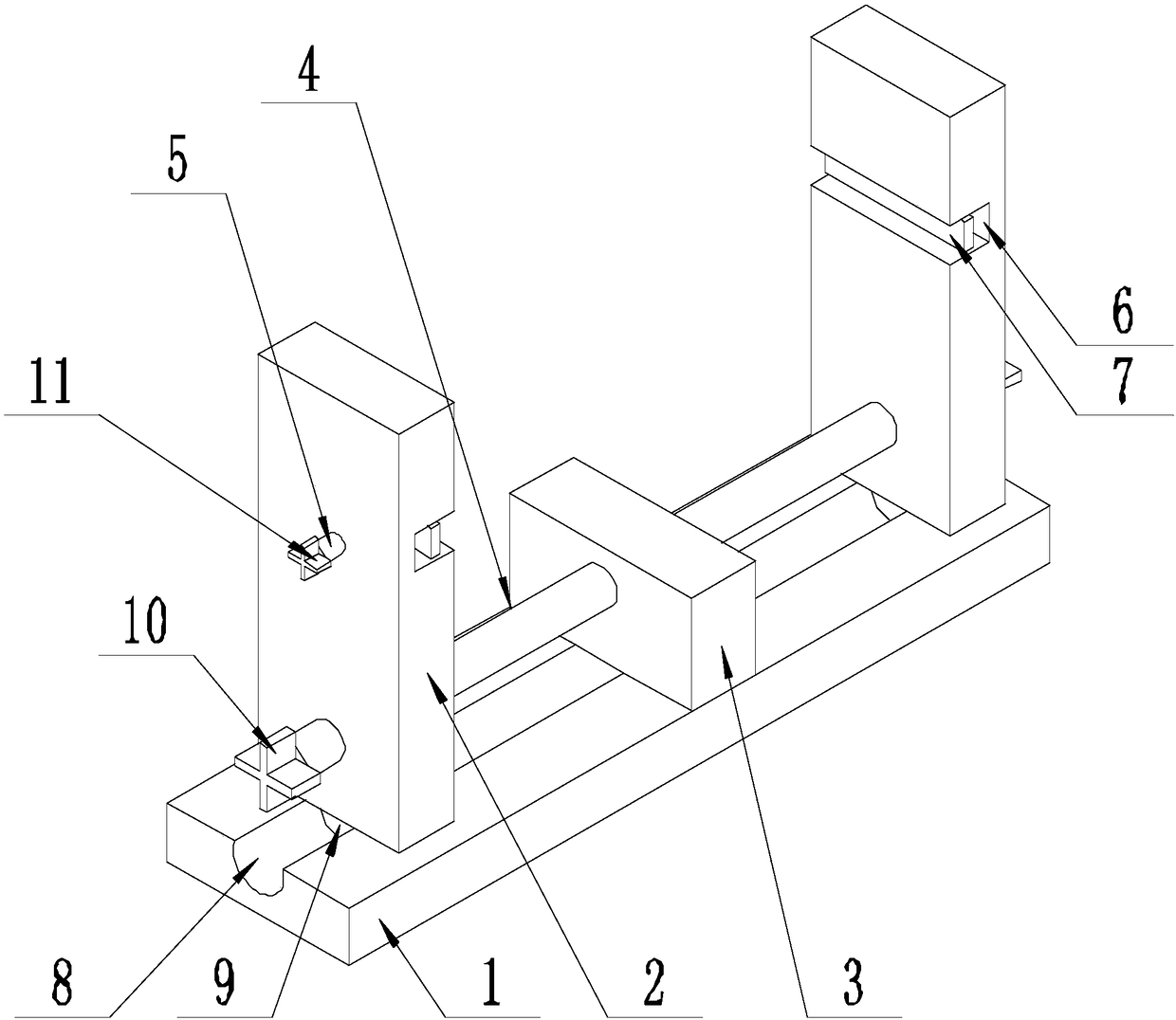

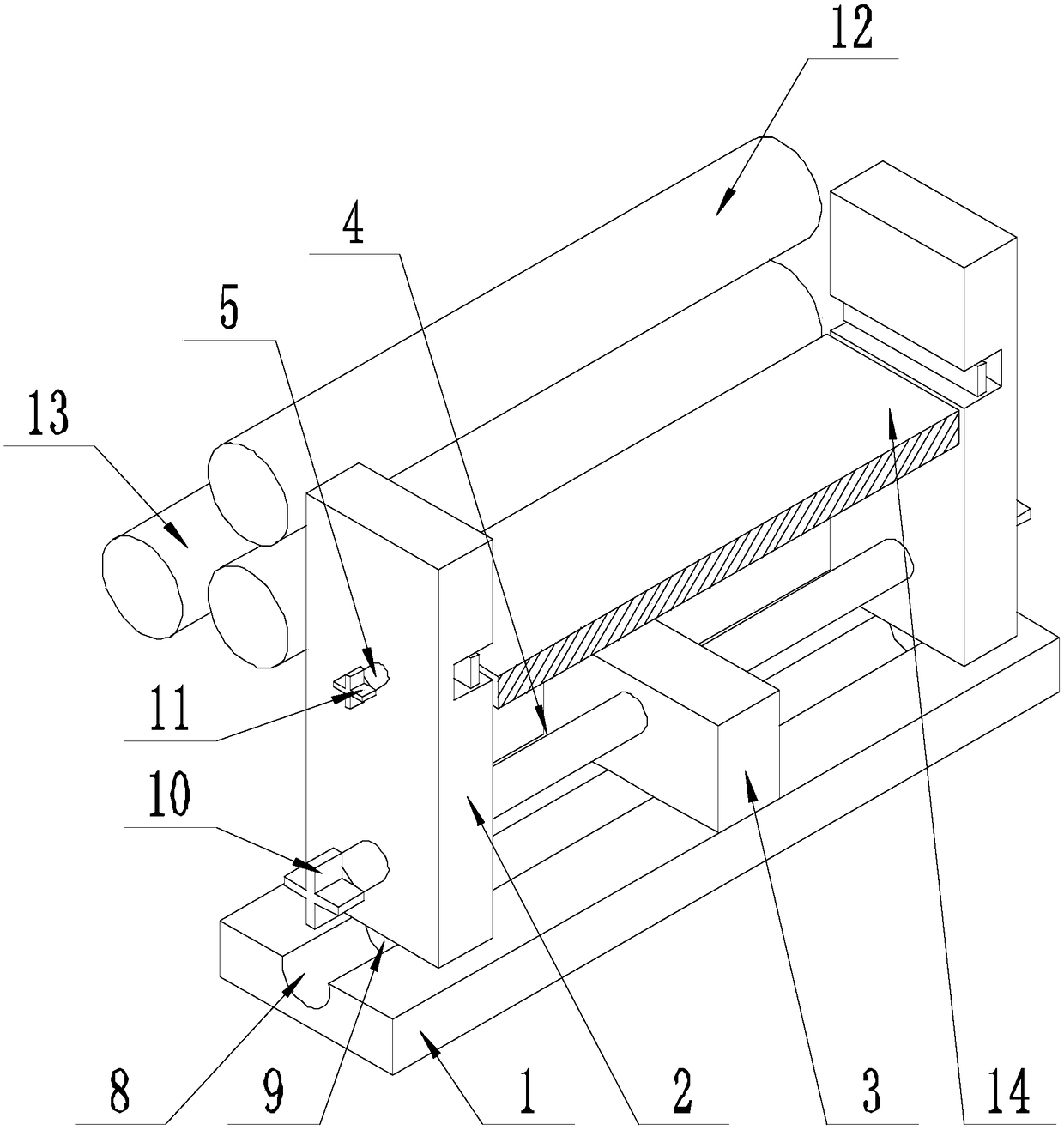

[0023] like Figure 1-Figure 2 As shown, the number 12 in the figure is the upper roll 12 of the plate bending machine, the number 13 is the lower roll 13 of the plate bending machine, and the number 14 is the conveyor belt 14 for transmitting the steel plate. The present invention facilitates the guiding device for turning over the barrel wall of the oil barrel, comprising a base plate 1, a baffle plate 2, a fixing block 3 and a screw I4. The block 3 is located between the two baffles 2, and the end of the fixed block 3 close to the bottom plate 1 is connected to the bottom plate 1. There are two screws I4, and one screw I4 passes through a baffle 2 vertically and rotates with the fixed block 3 The other screw rod I4 vertically passes through another baffle plate 2 and then is rotatably connected with the fixed block 3, and the screw rod I4 can rotate around its own axis and drive the corresponding baffle plate 2 to move.

[0024] When using this guiding mechanism, the baffl...

Embodiment 2

[0026] This embodiment is based on Embodiment 1 to further illustrate the present invention.

[0027] like Figure 1-Figure 2 As shown, the guide device of the present invention is convenient for turning over the barrel wall of the oil barrel. Grooves 6 are arranged on the opposite surfaces of the baffle plate 2, and the grooves 6 are through grooves. The end distribution of the steel plate protruding on both sides of the conveyor belt 14 during the advancing process on the conveyor belt 14 is put into the corresponding groove 6 .

[0028] Further, it also includes a screw rod II5, and a splint 7 is arranged in the groove 6, and the splint 7 is parallel to the baffle 2, and one end of the screw II 5 is located in the groove 6 after passing through the baffle 2, and is connected with the splint 7 . For ease of use, the pitch of the screw II5 is smaller than that of the screw I4. Rotate the screw I4 first to adjust the baffle plate 2 to the approximate position, then rotate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com