Self-propelled over-partition type machinery for removing stamens of corns

A detasseling machine and leaping technology, applied in the field of self-propelled leaping maize detasseling machines, can solve the problems affecting the industrialization of seed production, high cost and high labor intensity, so as to promote the industrialization of seed production and reduce tasseling. Cost and effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

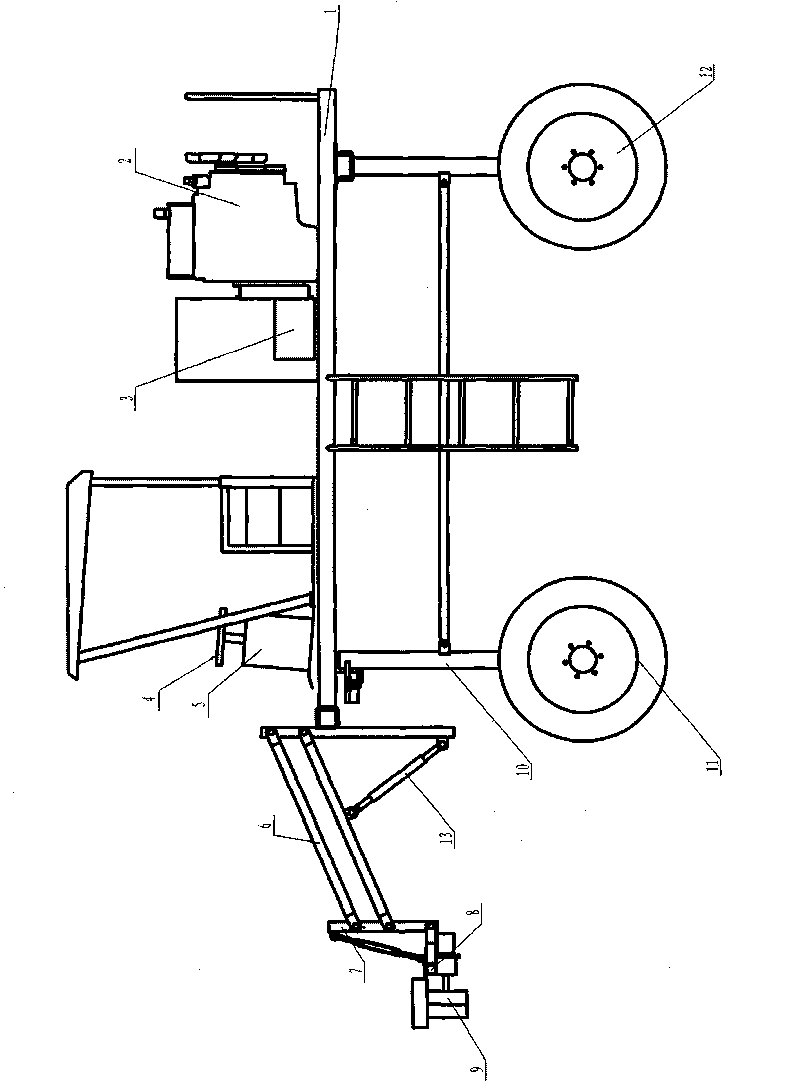

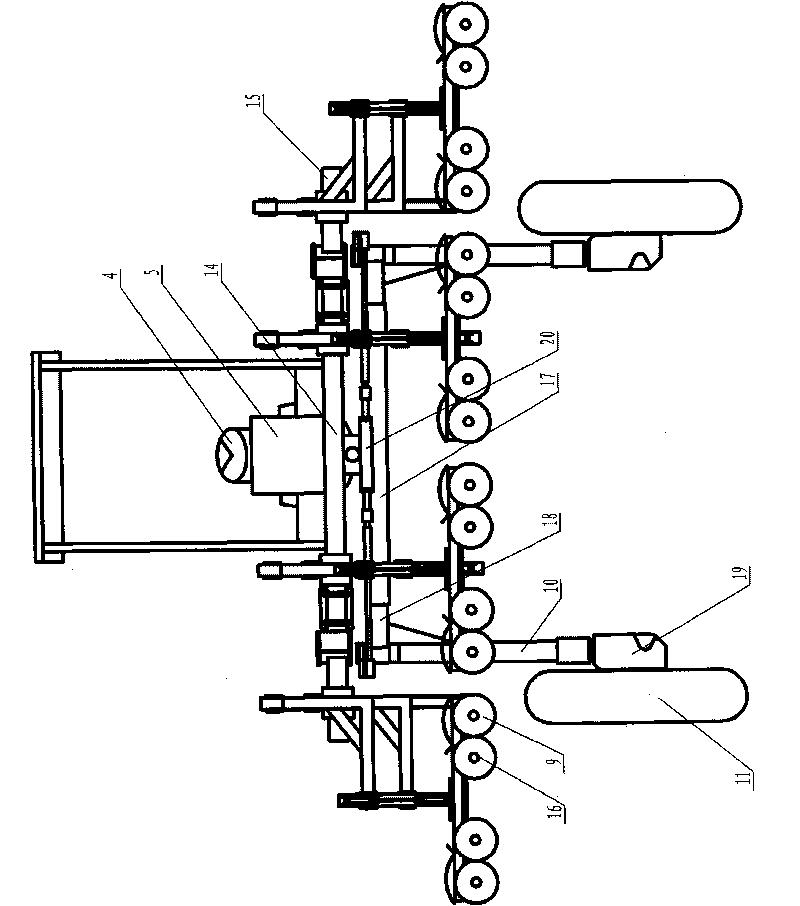

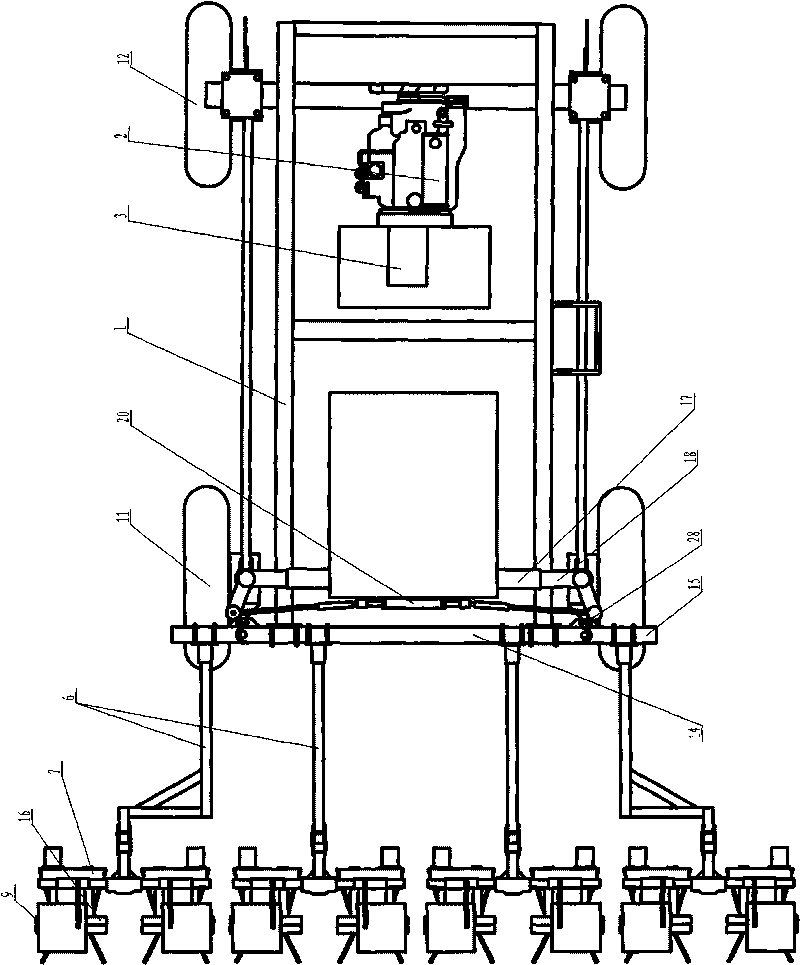

[0017] A self-propelled leaping corn detasseling machine, such as figure 1 , figure 2 , image 3 As shown, the hydraulic pump 3 driven by the engine 2 and the hydraulic control system are arranged on the frame 1 equipped with wheels, and the steering wheel 4 and the hydraulic steering gear 5 are also arranged on the frame 1. Steering hydraulic cylinder 20 controls the steering of front wheel 11 by connecting rod and crank throw, front wheel 11 and rear wheel 12 are installed respectively by support arm 10 at frame 1 front and rear girder bottom, and front and rear wheel 11,12 are respectively controlled by Driven by a hydraulic motor 19, the four-bar mechanism 6 controlled by the hydraulic cylinder 13 is evenly distributed on the support beam provided at the front of the frame 1, and the four-bar mechanism 6 controlled by the hydraulic cylinder 13 is respectively installed. male device. like Figure 4 , Figure 5 , Image 6 As shown, the roller maleting device is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com