Method for preparing activated carbon with chitosan used as raw material and obtainedactivated carbon

A technology for preparing activated carbon and chitosan, applied in the field of preparing activated carbon, can solve the problems of limited activated carbon production scale, small application field, high production cost, save production time, expand production scale, and achieve good product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

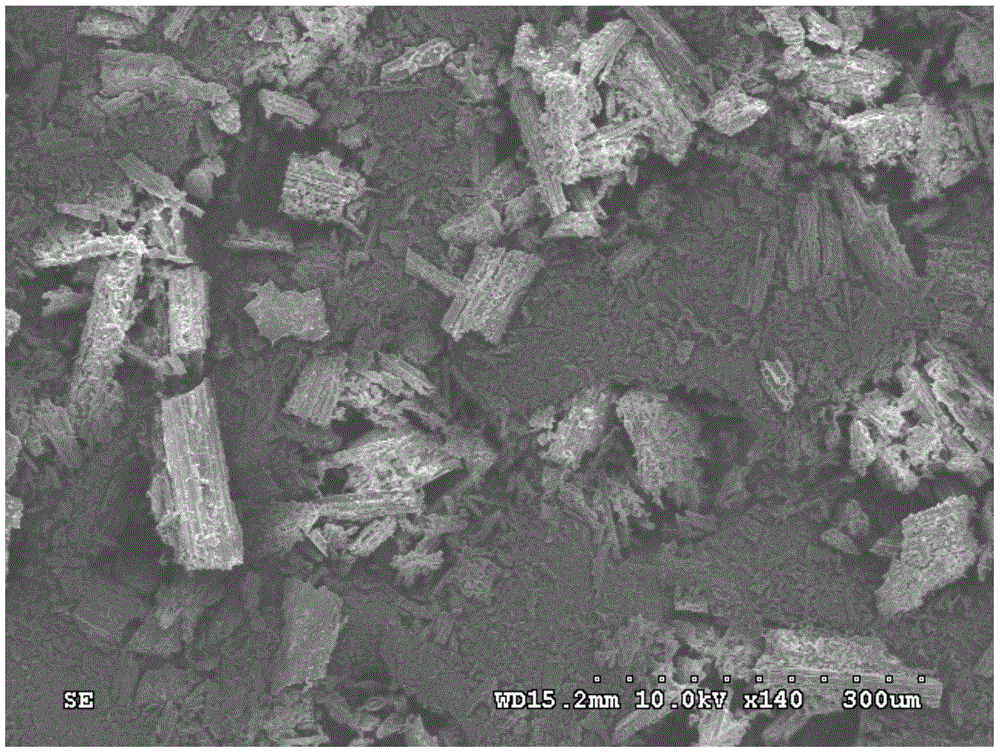

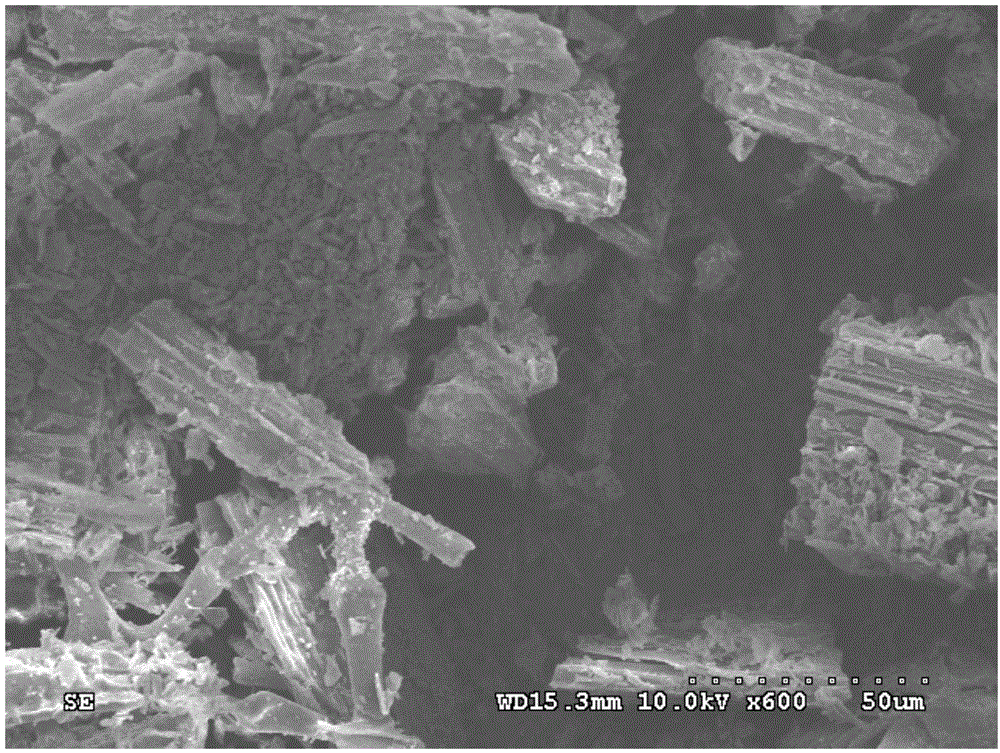

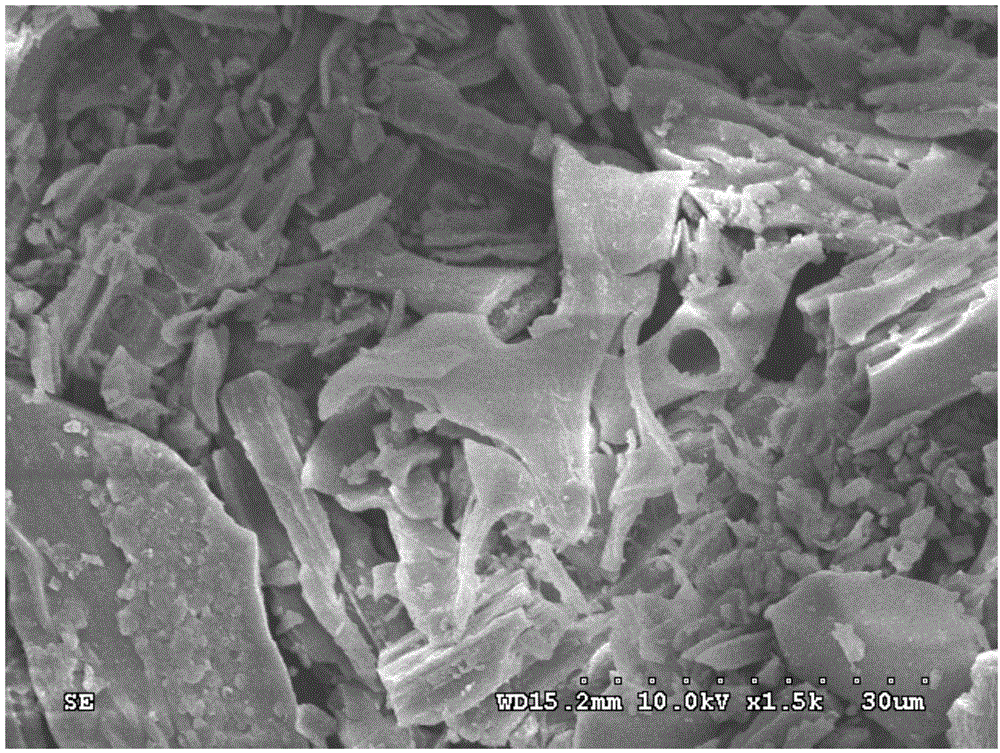

Image

Examples

Embodiment 1

[0032] a. take chitosan as raw material, fully disperse chitosan in the acetic acid aqueous solution of mass fraction 2%, make the chitosan colloidal solution of mass fraction 2.5%, and get rid of the air bubbles in the chitosan colloidal solution;

[0033] b. Hydrothermal carbonization, the above-mentioned chitosan colloid solution was transferred to a polytetrafluoroethylene high-pressure reactor, and the reactor was placed in an oven at 150° C. for hydrothermal reaction for 10 hours. After the reaction, the reaction kettle was taken out and cooled to room temperature naturally, the precipitated product was filtered, washed with distilled water until pH ≈ 7, and dried at 70°C for 8 hours to obtain carbonized chitosan;

[0034] c. Activation, mix the obtained carbonized chitosan and sodium hydroxide powder at a mass ratio of 1:10 and put them into a vacuum tube furnace to raise the temperature to 300°C at 2°C / min, keep the temperature for 2 hours, and then raise the temperatur...

Embodiment 2

[0038] a. take chitosan as raw material, fully disperse chitosan in the acetic acid aqueous solution of mass fraction 4%, make the chitosan colloidal solution of mass fraction 2.5%, and get rid of the air bubbles in the chitosan colloidal solution;

[0039] b. Hydrothermal carbonization, the above-mentioned chitosan colloid solution was transferred to a polytetrafluoroethylene high-pressure reactor, and the reactor was placed in an oven at 160° C. for hydrothermal reaction for 12 hours. After the reaction, take out the reaction kettle and cool it down to room temperature naturally, filter the precipitated product, wash it with distilled water until pH ≈ 7, and dry it at -50°C for 8 hours to obtain carbonized chitosan;

[0040] c. Activation, mix the obtained carbonized chitosan and sodium hydroxide powder at a mass ratio of 1:1 and put them into a vacuum tube furnace to raise the temperature to 400°C at 5°C / min, keep the temperature for 1 hour, and then raise the temperature at...

Embodiment 3

[0046] a. take chitosan as raw material, fully disperse chitosan in the acetic acid aqueous solution of mass fraction 2%, make the chitosan colloid solution of mass fraction 4%, and get rid of the air bubbles in the chitosan colloid solution;

[0047]b. Hydrothermal carbonization, the above-mentioned chitosan colloid solution was transferred to a polytetrafluoroethylene high-pressure reactor, and the reactor was placed in an oven at 180° C. for hydrothermal reaction for 24 hours. After the reaction, the reaction kettle was taken out and cooled to room temperature naturally, the precipitated product was filtered, washed with distilled water until pH ≈ 7, and dried at -20°C for 6 hours to obtain carbonized chitosan;

[0048] c. Activation, mix the obtained carbonized chitosan and sodium hydroxide powder according to the mass ratio of 1:2 and put them into a vacuum tube furnace to raise the temperature to 300°C at 2°C / min, keep the temperature for 2 hours, and then raise the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com