Catalyst with active component nano particles embedded in molecular sieve to crystallize, method and application

A technology of nanoparticles and active components, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high n-aldehyde selectivity, large particle size, low catalytic activity, etc., to prevent active components The effects of separation loss, good mechanical stability and long catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a catalyst in which active component nanoparticles are embedded in molecular sieve crystals, comprising the following steps:

[0048] 1) Co / SiO2 2 Existing Equal Volume Impregnation Preparation of Precursor Catalysts:

[0049] SiO 2 Treated in air at 200°C for 2h, then treated with Co(NO 3 ) 2 ·6H 2 O is the impregnation of the same volume as the Co source, the active metal Co loading is 20wt%, vacuum treatment for 1h, drying at 120°C for 12h, and roasting at 400°C for 2h to obtain the precursor particle catalyst; crush and screen the precursor particle catalyst to pass 80 mesh powder;

[0050] 2) TPAOH was used as template, and Al(NO 3 ) 3 9H 2 O is the source of Al, with Co / SiO 2 The Si dissolved out during the synthesis is used as the Si source;

[0051] Al(NO 3 ) 3 9H 2 O is dissolved in deionized water and ethanol (abbreviation: EtOH), and after stirring evenly, add the precursor catalyst powder obtained in step 1), add the templ...

Embodiment 2

[0059]A method for preparing a catalyst in which active component nanoparticles are embedded in molecular sieve crystals, comprising the following steps:

[0060] 1) Co / Al 2 o 3 Existing Equal Volume Impregnation Method Preparation of Precursor Catalysts

[0061] γ-Al 2 o 3 Treated in air at 200°C for 2h, then treated with Co(NO 3 ) 2 ·6H 2 O is impregnated with an equal volume of Co source, the active metal Co loading is 20wt%, vacuum treatment for 1h, drying at 120°C for 12h, and calcination at 400°C for 2h to obtain a precursor catalyst; crush and sieve the obtained precursor catalyst into a 20-mesh powder ;

[0062] 2) TPAOH was used as template, TEOS was used as Si source, and Co / Al 2 o 3 The Al dissolved during the synthesis process is used as the Al source;

[0063] Mix TEOS with deionized water and ethanol, stir evenly, add the precursor catalyst powder obtained in step 1), and then add template agent drop by drop, stir and mix evenly to obtain a synthetic so...

Embodiment 3

[0072] A method for preparing a catalyst in which active component nanoparticles are embedded in molecular sieve crystals, comprising the following steps:

[0073] Preparation of Co-Zr / SiO by Traditional Equal Volume Impregnation Method 2 catalyst:

[0074] SiO 2 Treated in air at 200°C for 2h, then treated with Co(NO 3 ) 2 ·6H 2 O and Zr(NO 3 ) 4 ·5H 2 O aqueous solution impregnated the equal volume, the active metal Co loading was 20wt%, the additive Zr loading was 6wt%, vacuum treatment for 1h, drying at 120°C for 12h, calcination at 400°C for 2h, to obtain Co-Zr / SiO 2 Precursor catalyst; Gained precursor catalyst is crushed and sieved into 60-mesh powder;

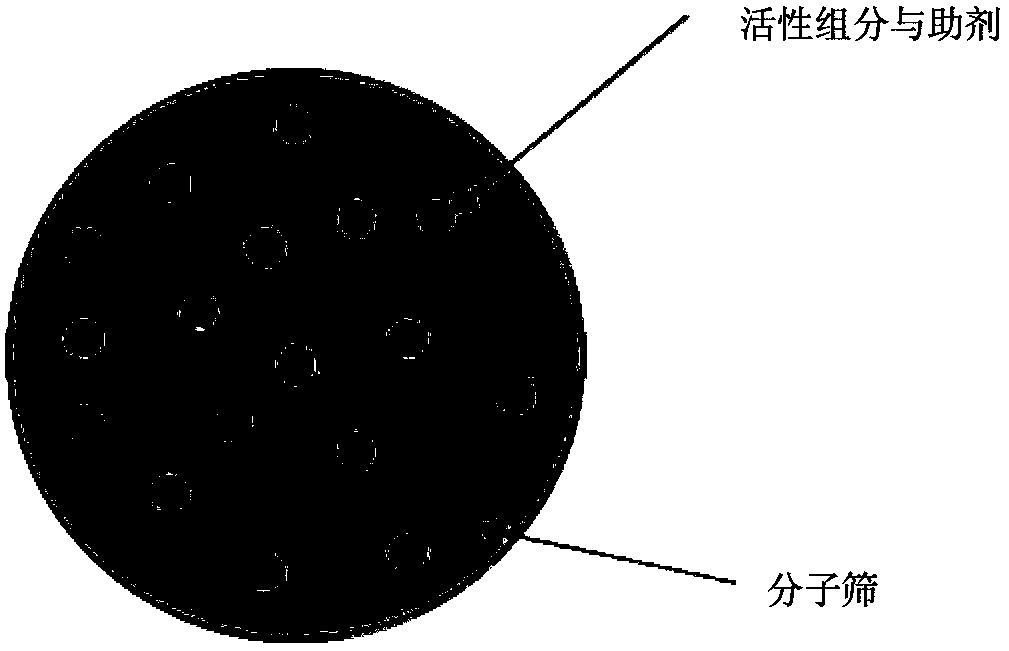

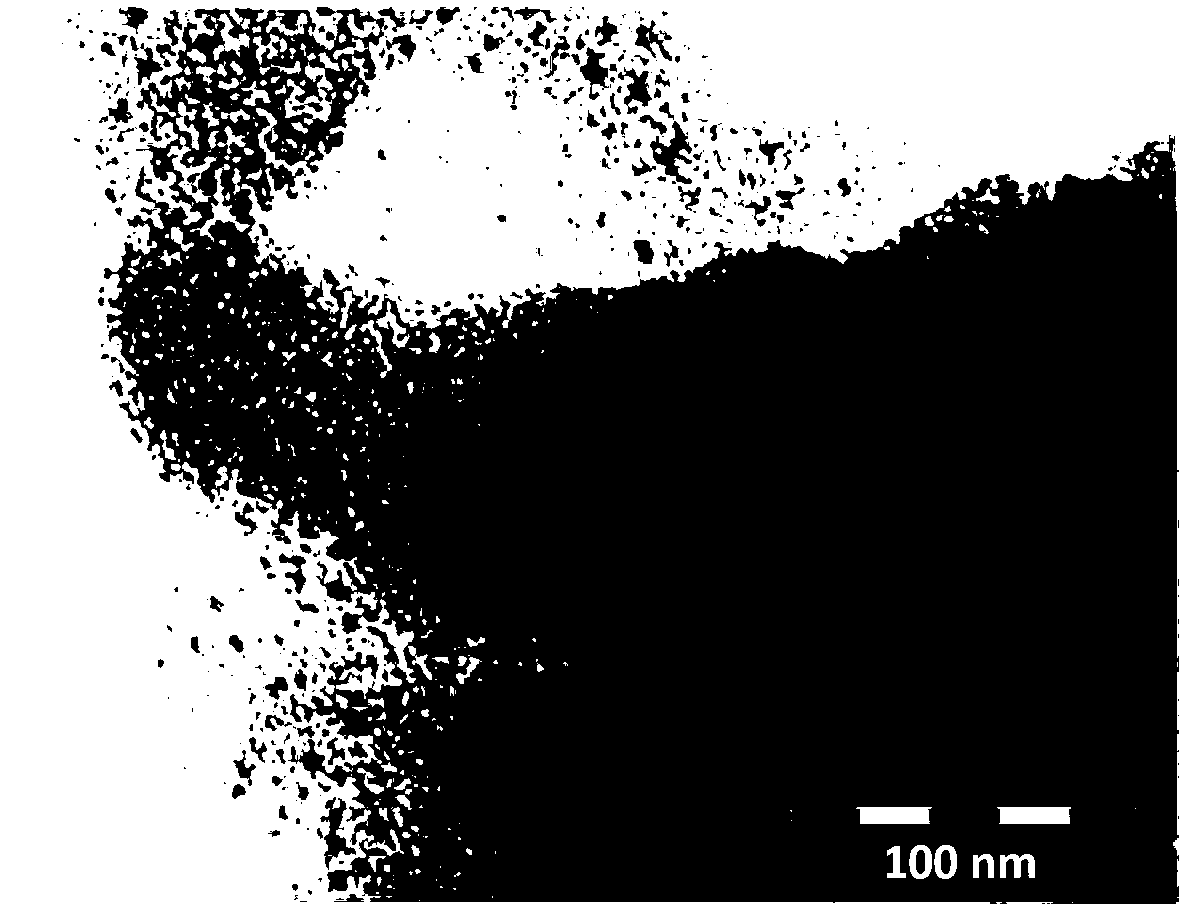

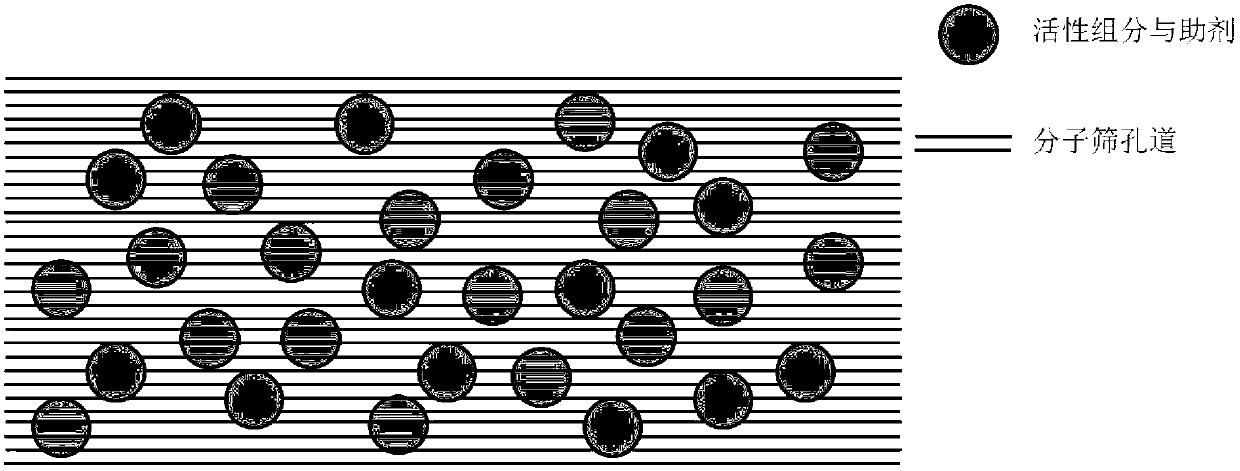

[0075] The rest of the operation steps are the same as in Example 1, and a novel structure Co-Zr·HZSM-5 molecular sieve catalyst is prepared. The Co-Zr·HZSM-5 catalyst includes Co active component nanoparticles, Zr additive particles and HZSM-5 molecular sieve, the Co active component nanoparticles are embedded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com