Insulating adhesive film for laminated bus bar and laminated bus bar

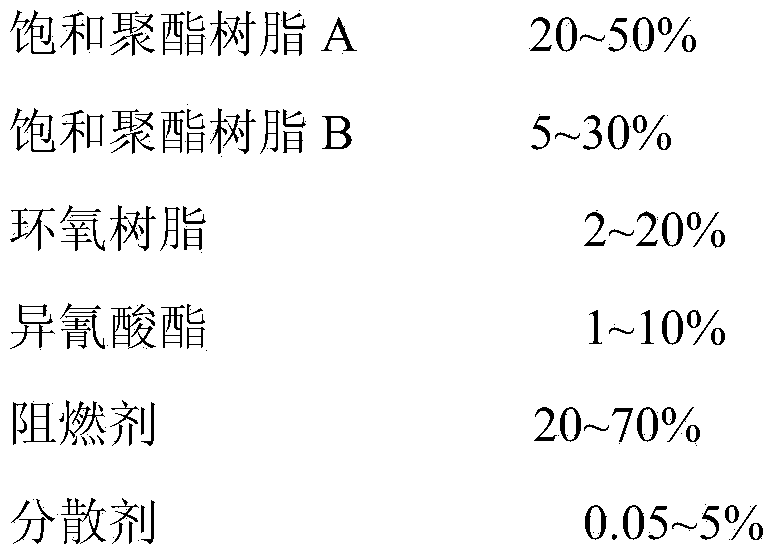

A technology of laminated busbar and insulating film, applied in insulators, adhesives, epoxy resins, etc., can solve the problems of substrate cracking, failure to meet, environmental protection performance not up to standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation of the present invention will be described below through examples.

[0055] 1. Synthesis of saturated polyester resin:

[0056] Add terephthalic acid, isophthalic acid, adipic acid, 2-methyl 1,3 propanediol, and ethylene glycol into a stainless steel reaction kettle with a stirrer, cooling pipe, and thermometer, start stirring, and then add relative The acid component is 0.04mol% catalyst antimony trioxide, under the condition of blowing nitrogen, the temperature of the reaction kettle is raised to 160° C. to 240° C., and the esterification reaction is carried out for 4 hours. Then release the pressure in the reactor. After 1 hour, the pressure in the reactor drops to 650Pa. The temperature of the reactor continues to rise to 265°C. Polymerization reaction to obtain saturated polyester resin.

[0057] 2. Determination of the composition of saturated polyester resin:

[0058] Dissolve 0.1g of saturated polyester resin in 5ml of deuterat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com